A kind of masonry method of rotary kiln

A technology of rotary kiln and kiln body, applied in the field of rotary kiln, which can solve the problems of looseness of the inner wall of refractory brick and kiln body and poor stability of refractory brick, and achieve the effect of increasing bonding strength and improving bonding stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0042] A method for building a rotary kiln, comprising the following steps:

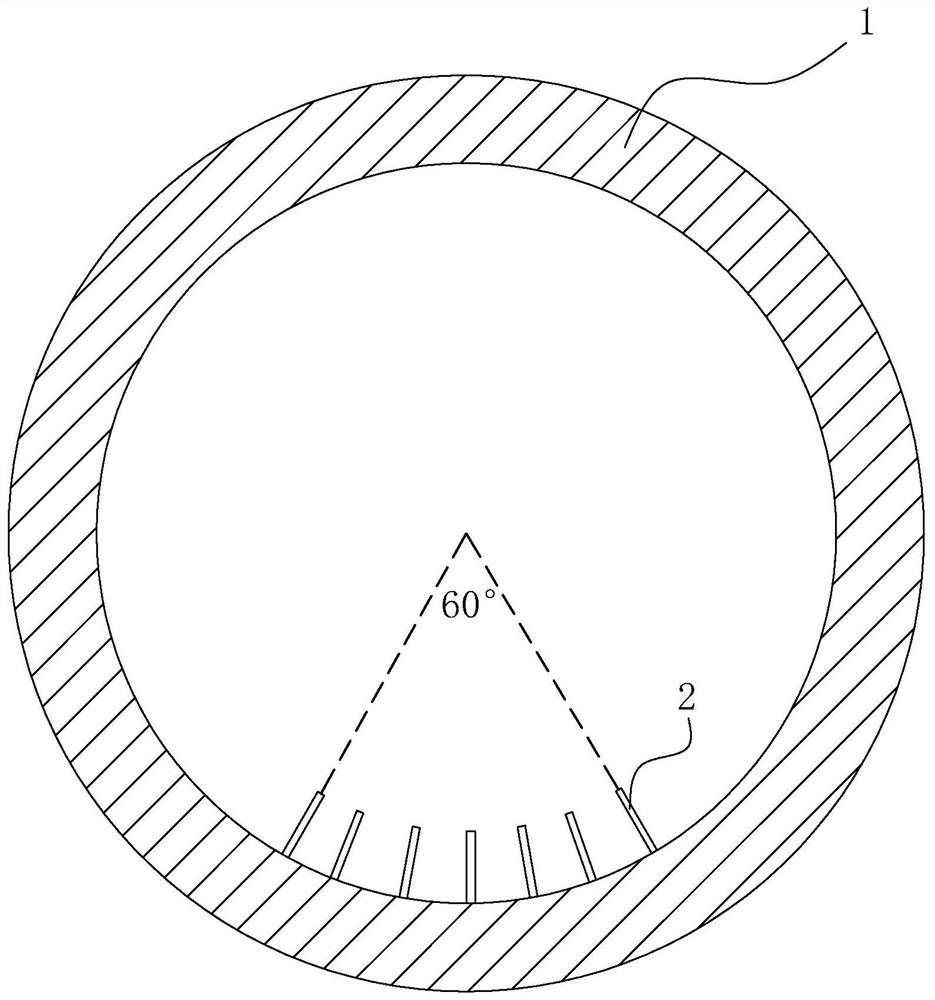

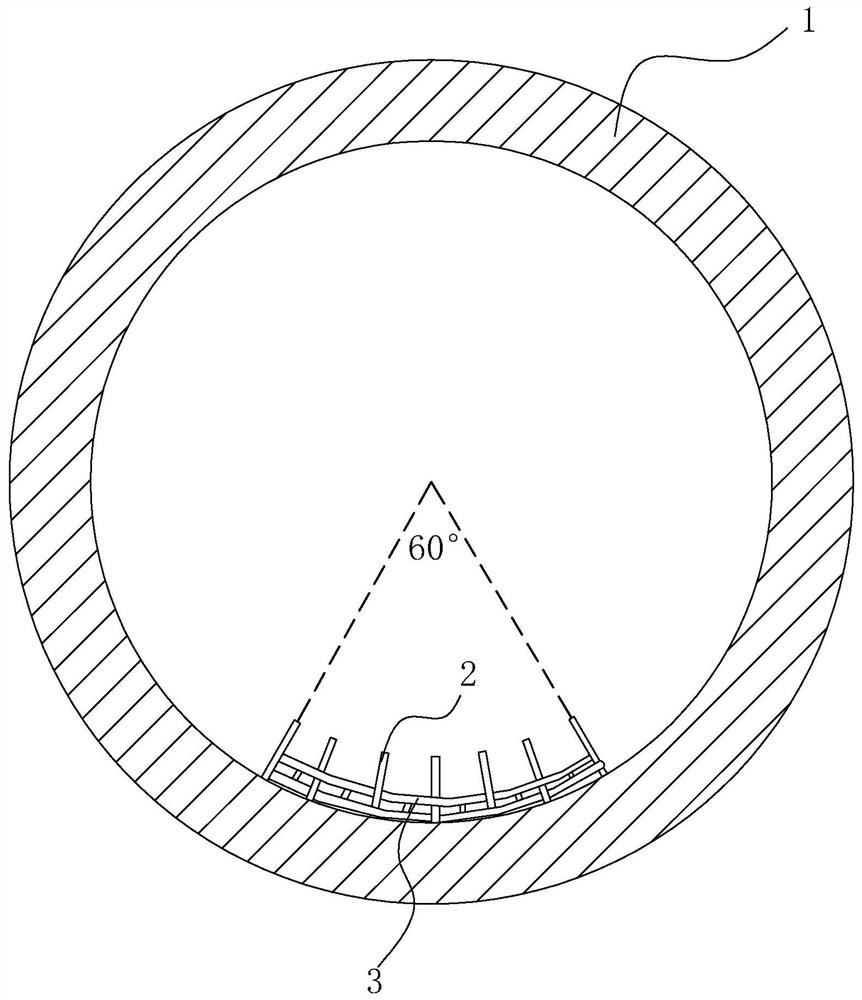

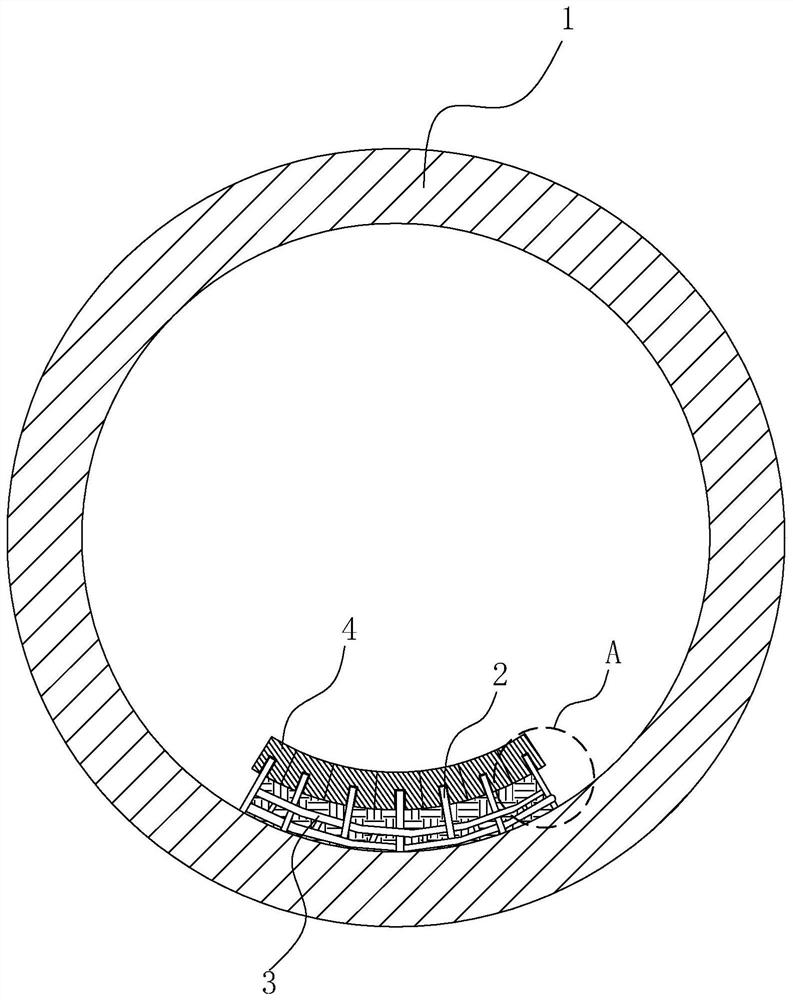

[0043] S1, such as figure 1 As shown, the kiln body 1 is placed horizontally, and a plurality of prefabricated rods 2 are welded on the inner wall of the kiln body 1. The prefabricated rods 2 are perpendicular to the inner wall of the kiln body 1. During the welding process, ensure that the plurality of prefabricated rods 2 are evenly spaced. The specific welding When using segmented welding, the range of each welding is 30-60 degrees of the central angle of the kiln body 1. In this embodiment, the welding range is preferably 60 degrees of the central angle of the kiln body 1, and the welding position is at the bottom of the kiln body 1. On both sides of the symmetrical ends, after each section of welding is completed, the kiln body 1 is rotated, and the rotation angle is the angle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com