A flange sealing structure suitable for high temperature and large heat flow environment and its installation method

A flange sealing and installation method technology, which is applied in the field of aerospace, can solve the problems of high production and maintenance costs, difficult to reuse, and inconvenient maintenance, and achieve the effects of simple structure, avoiding adverse effects, and reducing research and development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] Below in conjunction with accompanying drawing and specific embodiment content of the present invention is described in further detail:

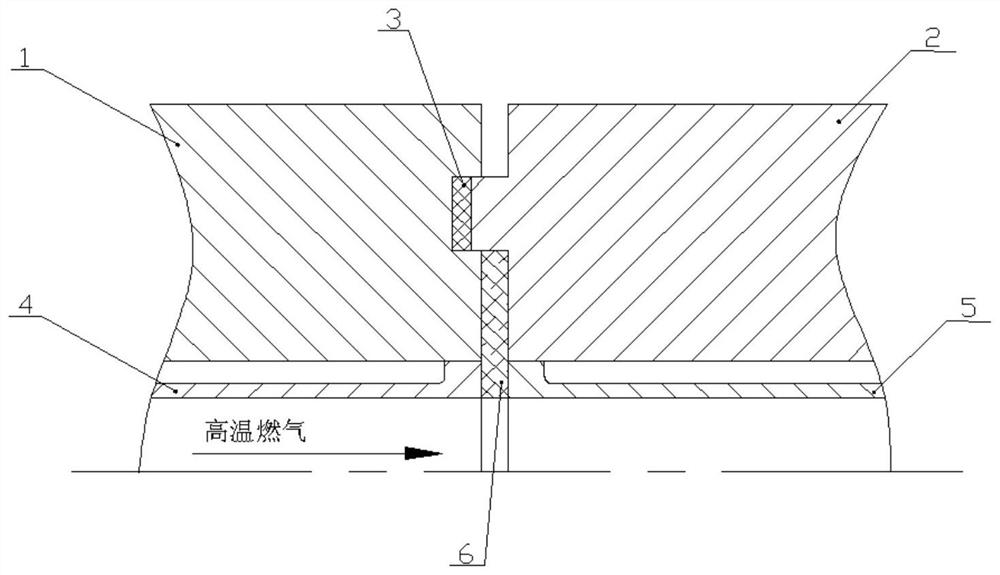

[0051] Such as figure 1 As shown, a flange sealing structure suitable for high temperature and large heat flow environment includes a first inner cylinder 4, a second inner cylinder 5, and matching groove flange 1 and tenon flange 2;

[0052] The groove of the groove flange 1 and the tenon of the tenon flange 2 respectively separate the butt end faces of the groove flange 1 and the tenon flange 2 into an inner butt end face and an outer butt end face;

[0053] The first inner cylinder 4 and the second inner cylinder 5 are respectively welded on the inner sides of the groove flange 1 and the tenon flange 2, and there is a gap between the two inner cylinders and the two flanges for filling cooling water to form a sandwich structure ; The butt end surfaces of the two inner cylinders are respectively flush with the inner butt end surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com