Throttling and heating production device and throttling and heating production method for well mouth of gas well

A production device and production method technology, applied in isolation devices, wellbore/well components, pipeline heating/cooling, etc., can solve the problems of reducing gas well development and production operation costs, shortening production adjustment and shutdown periods, and high requirements for downhole tools , to achieve the effect of reducing the cost of gas well development and production operation, and shortening the period of production adjustment and shutdown.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

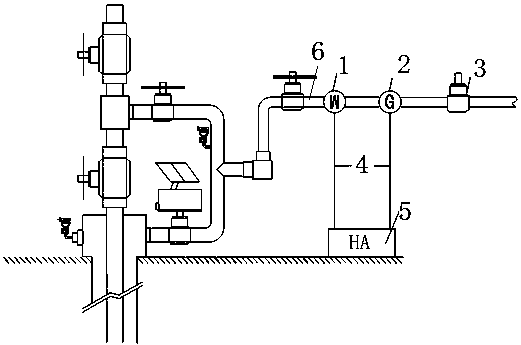

[0028] In order to overcome the cumbersome construction, heavy workload, and high overall cost of the existing downhole throttling process; the downhole throttling process has high requirements for downhole tools, and the maintenance construction is difficult, costly, and long-term, with high safety risks. The maintenance process Problems that affect the normal production of gas wells. The present invention provides as figure 1 Shown is a gas well wellhead throttling heating production device and method. The present invention does not require a downhole throttling device, meets the requirements of medium and low pressure gas gathering technology and solves the problem of single well pipeline freezing in winter, further reduces the cost of gas well development and production operation, shortens Adjust production and shut down cycle, so that gas well throttling is transferred from downhole uncontrollable to surface controllable state.

[0029] A gas well wellhead throttling hea...

Embodiment 2

[0034] Based on Embodiment 1, in this embodiment, both the heat tracing device 1 and the impeller expander 2 are electrically connected to the power system 5 through the power wire 4 .

[0035] The heat tracing device 1 is an electric heater.

[0036] An emergency cut-off valve is provided downstream of the impeller expander 2 .

[0037] The turbo expander 2 is driven by the high-pressure natural gas produced by the production pipeline 6 to generate electricity and store the electric energy in the power system 5 .

[0038] The control valve 3 is a flow control valve.

[0039] A gas well wellhead throttling heating production method, the specific steps are:

[0040] First, the impeller expander 2 and the heat tracing device 1 are connected to the power supply system 5 through the power wire 4, the impeller expander 2 uses the high-pressure natural gas produced by the production pipeline 6 to drive power generation and stores the electric energy in the power supply system 5, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com