Combined frame-type hot press

A hot-press, frame-type technology, applied in the direction of plywood presses, veneer presses, wood processing appliances, etc., can solve the problem of uneven heat transfer performance of hot-pressed plates, inability to meet the use of lamination performance, and inability to form hot-pressed structure and other problems, to avoid waste of hot pressing resources, improve combination performance, and improve utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

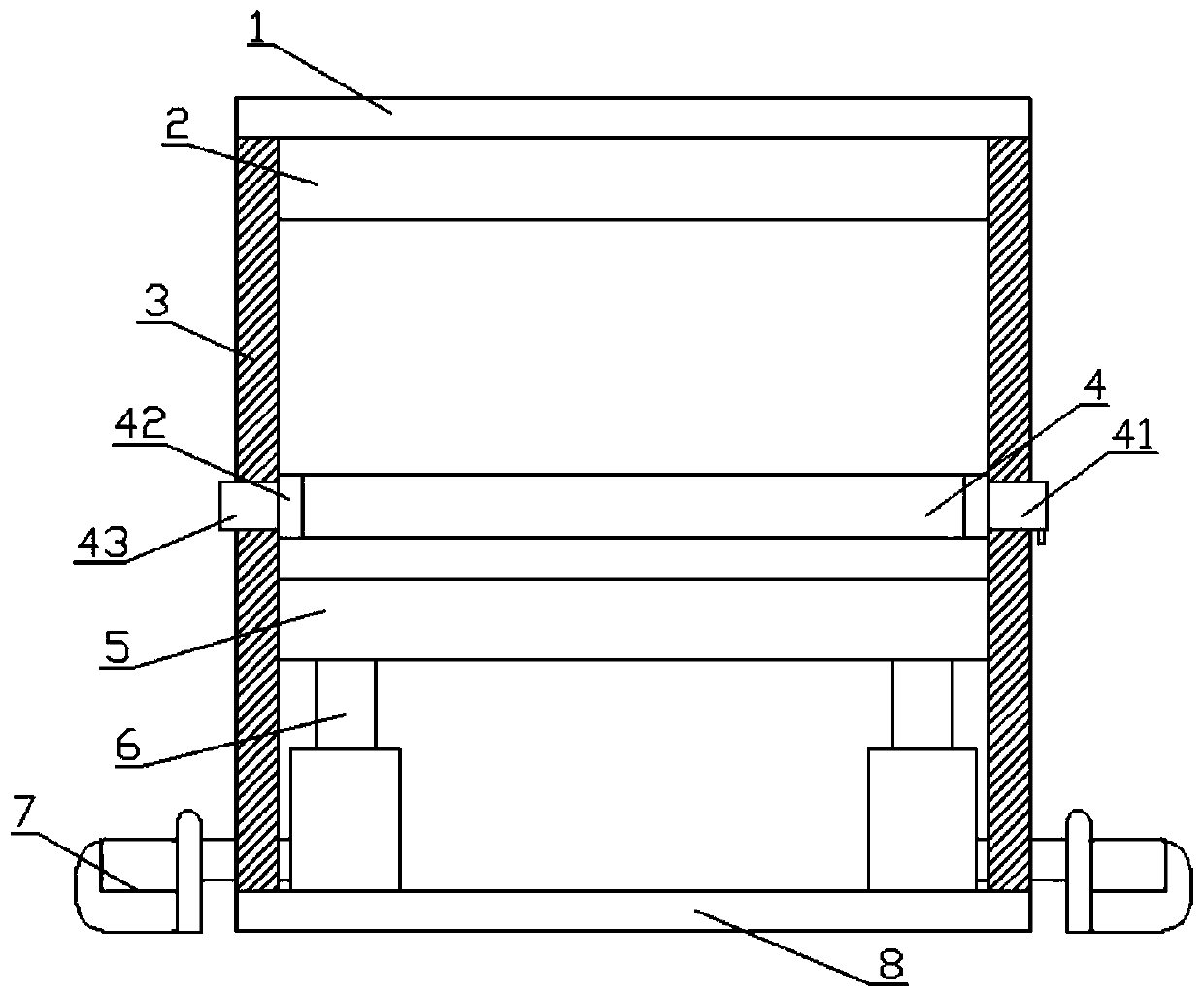

[0023] as attached figure 1 to attach Figure 4 shown

[0024] The present invention provides a combined frame type hot press, comprising a fixed head 1, a top plate 2, a guide plate 3, a hot pressing plate 4, a bottom plate 5, a hydraulic rod 6, a hydraulic pump 7 and a platform 8, the lower end of the fixed head 1 Both sides are provided with guide plate 3, and one side of guide plate 3 is provided with top plate 2, and the bottom of this top plate 2 is provided with hot pressing plate 4; The bottom of described hot pressing plate 4 is provided with base plate 5, and the bottom plate 5 The lower end is provided with a hydraulic rod 6, and one side of the hydraulic rod 6 is provided with a hydraulic pump 7, wherein the bottom end of the hydraulic rod 6 is provided with a platform 8; , button cavity 44 and stable layer 45, and the two sides of hot pressing plate 4 are respectively provided with peripheral block 43 or driving block 41, and one side of this peripheral block 43...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com