A kind of preparation method of chitosan phosphorus removal material and chitosan phosphorus removal material

A technology of chitosan and metal salts, which is applied in chemical instruments and methods, water treatment parameter control, and other chemical processes, can solve the problems of large consumption of acid and alkali solutions, cumbersome preparation process, etc., and achieve uniform load, rich sources, The effect of non-pyrogenic reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

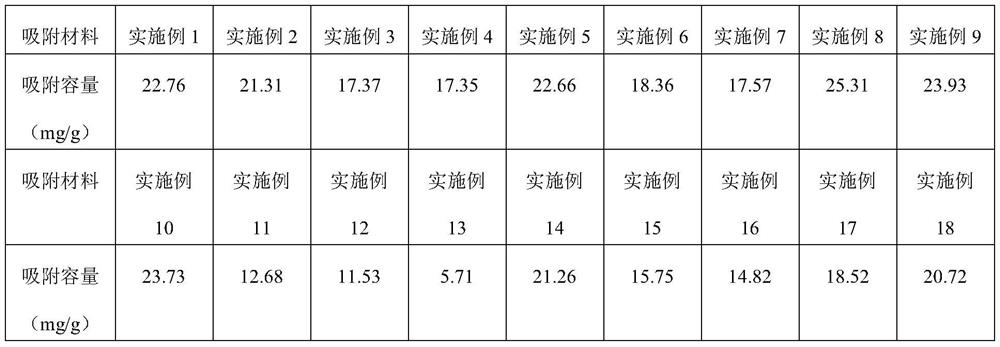

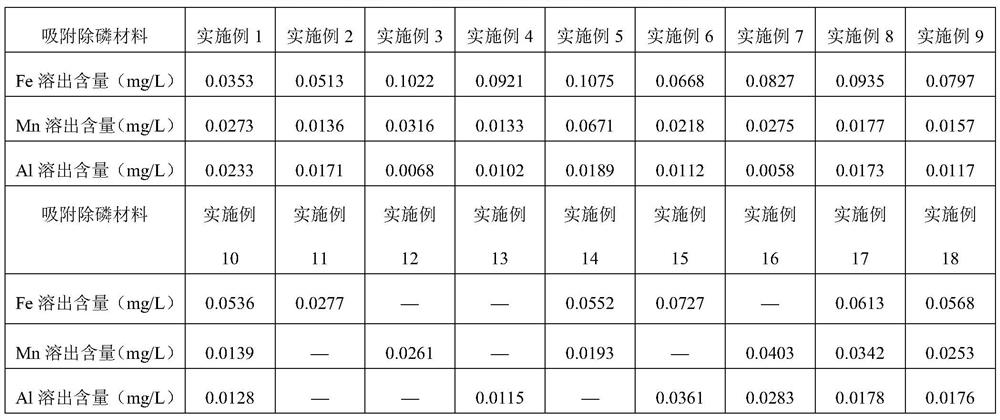

Examples

Embodiment 1

[0047] Take 50g of chitosan with a particle size of 1mm, a degree of deacetylation of 90%, and a viscosity-average molecular weight of 100,000, add it to a 10L aqueous solution, stir at a speed of 60 rpm to make it form a suspension, add 41g Fe(NO) 3 ) 3 , 26g MnSO 4 , 94g Al(NO 3 ) 3 , After stirring evenly, use spray drying technology to dry the adsorption and phosphorus removal material. The spray drying conditions are: inlet air temperature 150 °C, outlet air temperature 80 °C, drying time 1.5S, maximum water evaporation 8Kg / h, peristaltic pump feeding 2L / h, dry air flow 1.5m 3 / min, spray gas flow 0.5m 3 / h, the nozzle diameter is 2mm, and the dry powder recovery rate is 95%.

Embodiment 2

[0049] Weigh 41g Fe(NO 3 ) 3 , 26g MnSO 4 , 94g Al(NO 3 ) 3 , add it into 16L of water, stir at a speed of 50 rpm to dissolve it, add 50g of chitosan with a particle size of 1 mm, a degree of deacetylation of 90%, and a viscosity average molecular weight of 300,000, stir and mix evenly, and then use spray drying The adsorption and dephosphorization material is obtained by technical drying. The spray drying conditions are as follows: the inlet air temperature is 200°C, the outlet air temperature is 100°C, the drying time is 1.5S, the maximum water evaporation is 8Kg / h, the peristaltic pump feed is 2L / h, and the drying air flow rate is 1.5m. 3 / min, spray gas flow 0.5m 3 / h, the nozzle diameter is 2mm, and the dry powder recovery rate is 95%.

Embodiment 3

[0051] Take 30g of chitosan with a particle size of 3mm, a degree of deacetylation of 80%, and a viscosity-average molecular weight of 250,000, add it to an 8L aqueous solution, stir at a speed of 30 rpm to form a suspension, and add 54g of FeCl 3 , 59.4g MnCl 2 , 51.3g Al 2 (SO 4 ) 3 , After stirring evenly, the adsorption and dephosphorization material is obtained by drying by spray drying technology. The spray drying conditions are: inlet air temperature 100°C, outlet air temperature 50°C, drying time 1S, maximum water evaporation 10Kg / h, peristaltic pump feeding 2L / h h, dry air flow 1m 3 / min, spray gas flow 0.2m 3 / h, the nozzle diameter is 3mm, and the dry powder recovery rate is 95%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com