Semi-direct-drive axial composite dual-port permanent magnet synchronous wind-driven generator

A technology of wind generator and permanent magnet synchronization, which is applied in the direction of wind generator, wind generator combination, wind generator control, etc. It can solve the problems of increasing the volume of the generator, increasing the installation and transportation, and increasing the power of a single machine, so as to reduce the The difficulty of installation and transportation, the reduction of processing and manufacturing costs, and the effect of reducing volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

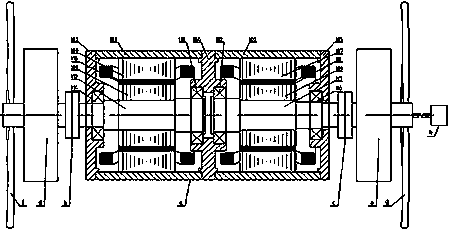

[0015] Such as figure 1 As shown, the present invention provides a semi-direct-drive axial compound dual-port permanent magnet synchronous wind generator, which includes a generator a, a left coupling b, a right coupling c, a left Side speed increaser d, right side speed increaser e, one group of blades f, another group of blades g, yaw mechanism h; the generator a includes casing one 101, casing two 102, and left end cover 103 , middle end cover 104, right end cover 105, winding stator core one 106, winding stator core two 107, rotor core one 108, rotor core two 109, permanent magnet one 110, permanent magnet two 111, rotating shaft one 112, rotating shaft two 113, bearing one 114, bearing two 115, bearing three 116, bearing four 117...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com