Shaftless generator and axle sensing communication system

A generator, shaftless technology, applied in electromechanical devices, electrical components, electric components, etc., can solve problems such as hidden safety hazards, waste of management costs, and inability to set up passenger cars, so as to reduce potential safety hazards and improve operational efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

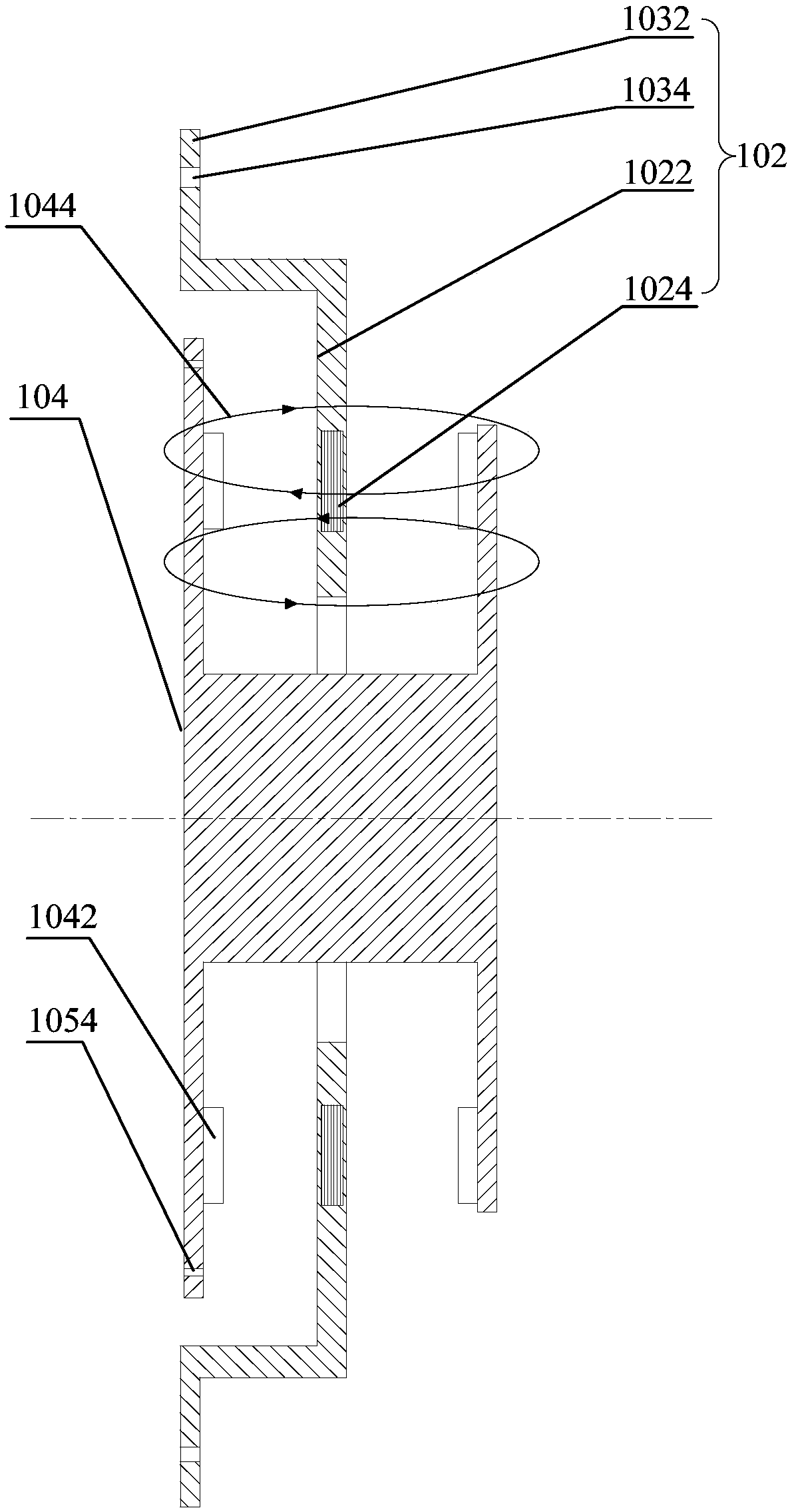

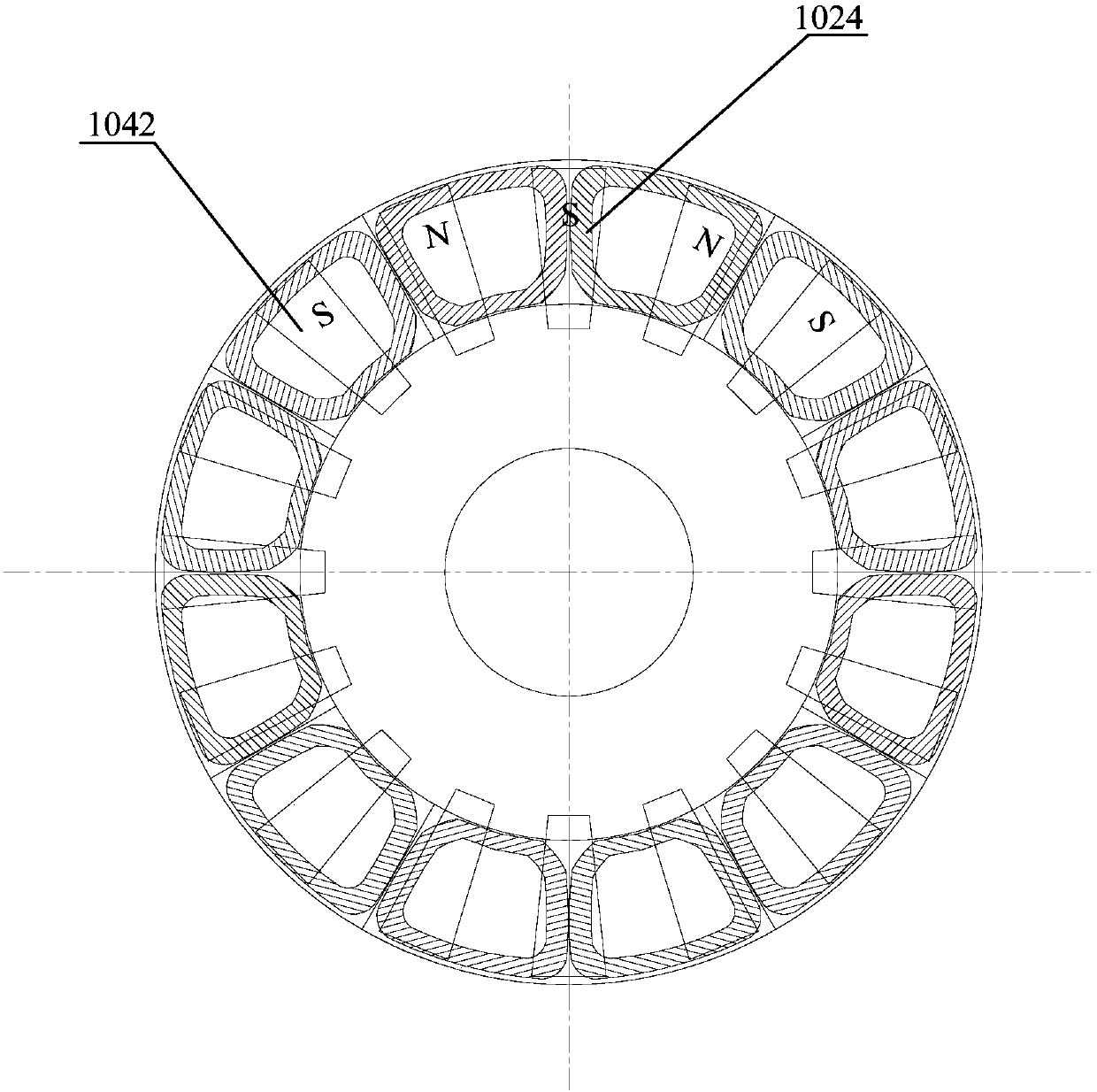

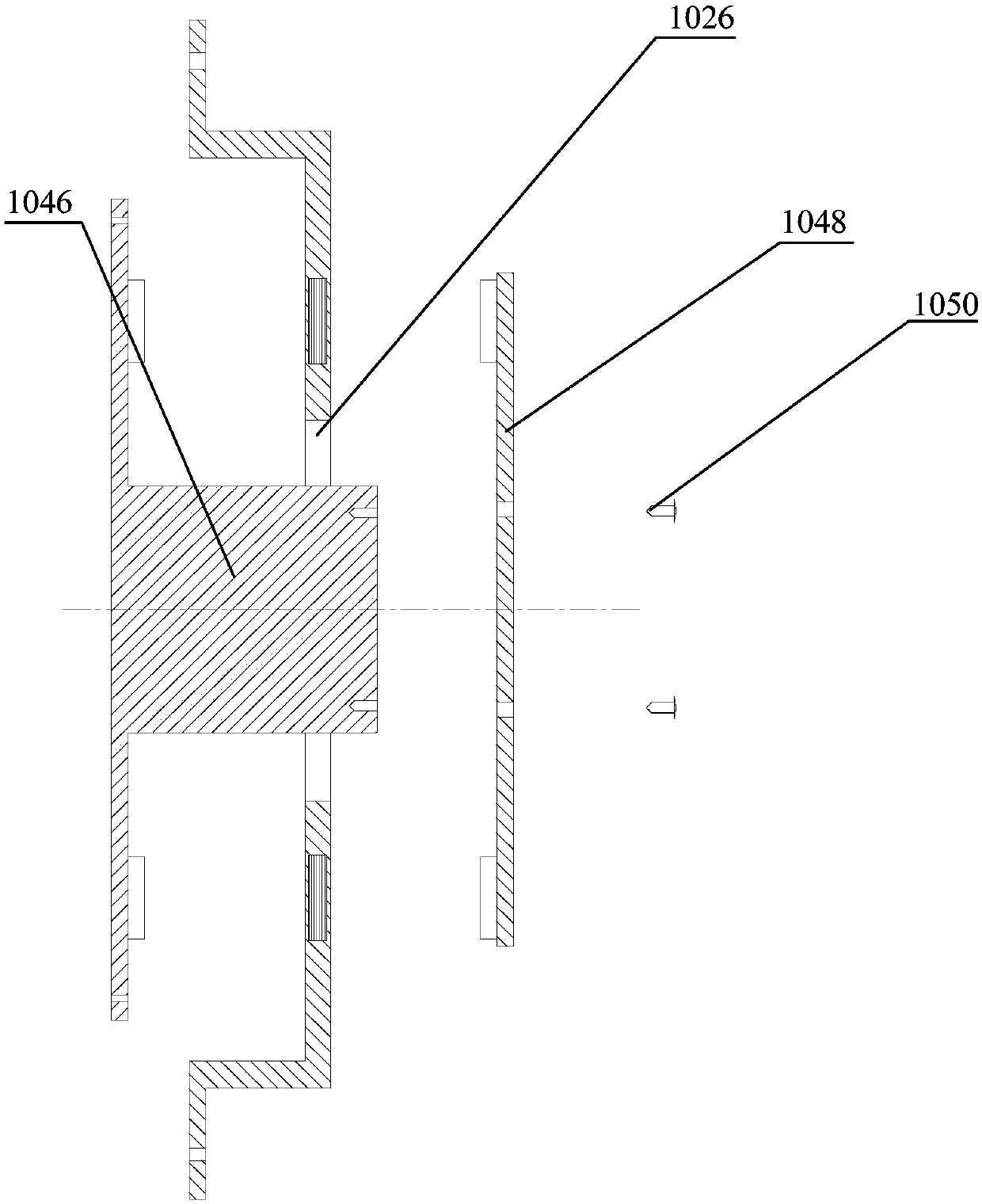

[0044] like image 3 As shown, in the above embodiment, preferably, the bottom plate is provided with a first through hole 1026; the rotor disk includes a first rotor disk 1046 and a second rotor disk 1048 which are oppositely arranged, and a first rotor disk 1046 is fixedly arranged on the first rotor disk 1046; A connecting post, the first connecting post can be detachably connected to the second rotor disk 1048 through the through hole, wherein the permanent magnets 1042 are arranged in a built-in tangential type, and the diameter of the first through hole 1026 is larger than the diameter of the first connecting post .

[0045] In this embodiment, by opening the first through hole 1026 in the central area of the accommodation groove 1022, the separated first rotor disk 1046 and the second rotor disk 1048 can pass through through the first connecting column provided between the two disks. The first through hole 1026 is connected by a plurality of circumferentially arrange...

Embodiment 2

[0047] like Figure 4 As shown, in any of the above embodiments, preferably, the rotor disk includes a third rotor disk, a fourth rotor disk and a second connecting column arranged between the third rotor disk and the fourth rotor disk. The three rotor disks, the fourth rotor disk and the second connecting column are integrally formed; the stator 102 includes a first half stator disk 1028 and a second half stator disk 1230 that can be spliced with each other, and the first half stator disk 1028 is provided with a second Half circular hole, the second half stator plate 1230 is provided with a second semicircular hole to form a second through hole after splicing, wherein the permanent magnets 1042 are arranged in a built-in tangential type, and the diameter of the second through hole is larger than that of the second connection The diameter of the column.

[0048] In this embodiment, the rotor 104 is still formed by two rotor disks. The difference from the above arrangement i...

Embodiment 3

[0050] like Figure 5 As shown, in any of the above embodiments, preferably, the number of rotor disks is one, that is, the fifth rotor disk 1052, the permanent magnets 1042 on the fifth rotor disk 1052 are arranged in a built-in tangential type, and the fifth rotor disk 1052 can extend into the accommodation groove 1022 in the axial direction, and the permanent magnet 1042 and the coil 1024 are arranged correspondingly in the radial direction.

[0051] In this embodiment, only one fifth rotor disk 1052 may be used, and a plurality of permanent magnets 1042 arranged in a tangential manner are also arranged on the fifth rotor disk 1052. Compared with the above two arrangements, on the one hand, There is no need to open a central hole on the stator 102, and the structure is simpler. On the other hand, relatively, the power generation efficiency is relatively low.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com