Sound absorption and insulation composite member and transformer

A composite part, sound absorption and isolation technology, applied in the direction of transformer/inductor noise damping, etc., can solve problems such as mismatching noise characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

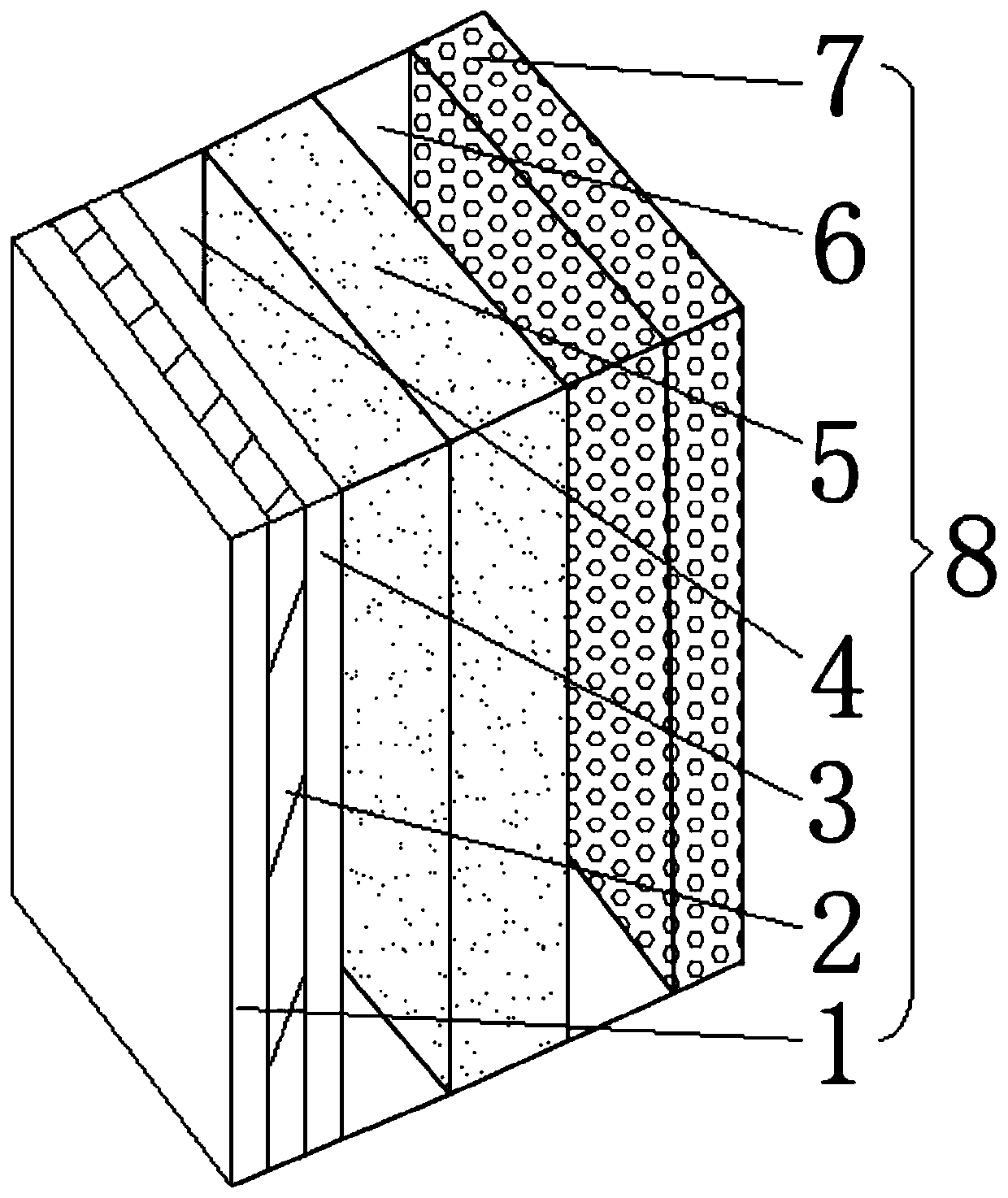

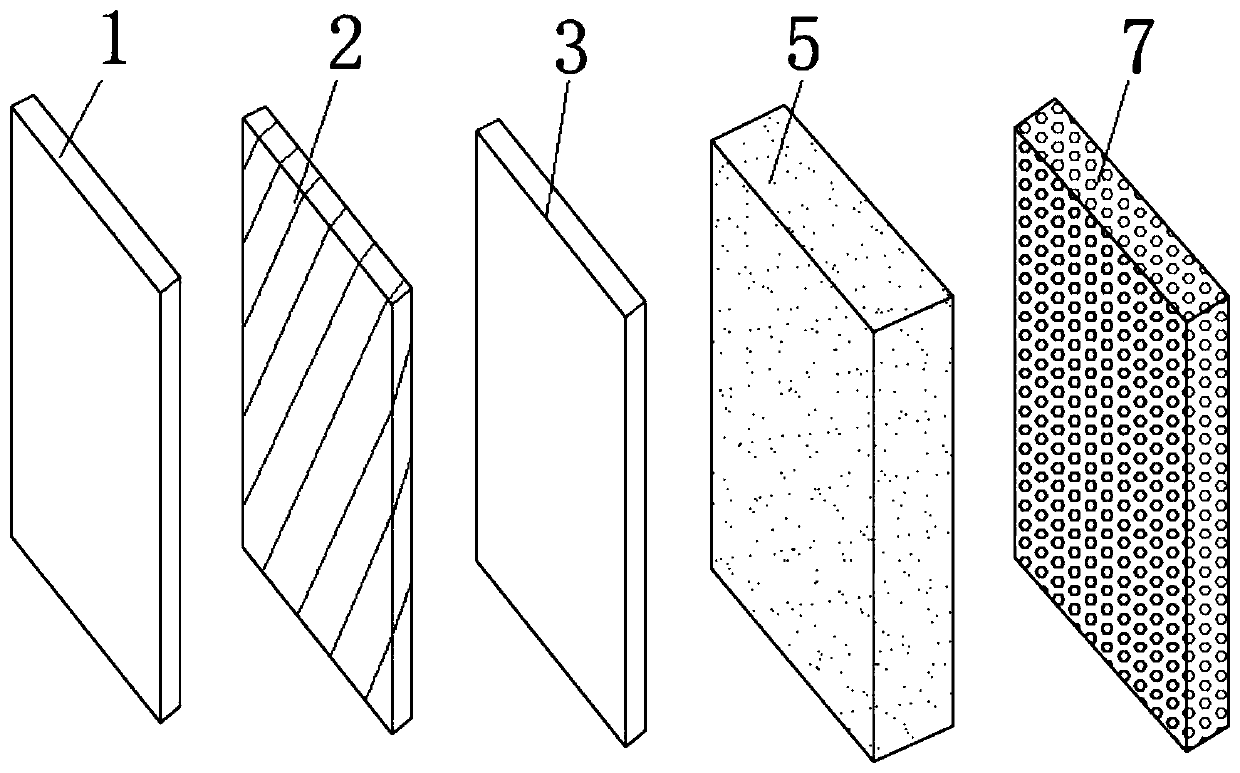

[0034] The present invention provides a transformer, which includes a transformer body and such as figure 1 The sound-absorbing and insulating composite part 8 shown is fixedly connected to the outer side of the main body of the transformer. Specifically, an angle iron is welded on the outer side of the outer wall of the transformer main body, and the sound-absorbing and insulating compound 8 is fixed on the angle iron. The sound-absorbing and insulating composite part 8 includes a constrained damping sound-insulating component and an impedance composite sound-absorbing component, and the impedance composite sound-absorbing component is arranged near the outer side of the transformer main body. Specifically, the impedance composite sound-absorbing components can be connected by square steel, and the constrained damping sound-insulation components can be connected by bonding. Of course, the sound-absorbing and insulating composite part 8 can also be used to reduce noise of oth...

Embodiment 2

[0044] This embodiment provides a transformer, which includes a transformer body and such as figure 1 The sound-absorbing and insulating composite 8 shown is arranged on the outside of the transformer main body, wherein the structure of the sound-absorbing and insulating composite 8 is the same as that of the sound-absorbing and insulating composite 8 provided in Embodiment 1, However, the material and size of the sound-absorbing and insulating composite 8 are different from those of the sound-absorbing and insulating composite 8 in Embodiment 1.

[0045] In this embodiment, both the rigid base layer 3 and the rigid constrained layer 1 are steel plates with a thickness of 1 mm, and the elastic damping layer 2 is a butyl rubber plate with a thickness of 4 mm; the micro-perforated plate 7 has a thickness of 0.5 mm and a hole diameter of Aluminum micro-perforated plate of 1 mm with a hole spacing of 15 mm; the fiber material layer is a layer of polyester fiber cotton with an area...

Embodiment 3

[0047] This embodiment provides a transformer, which includes a transformer body and such as figure 1 The sound-absorbing and insulating composite 8 shown is arranged on the outside of the transformer main body, wherein the structure of the sound-absorbing and insulating composite 8 is the same as that of the sound-absorbing and insulating composite 8 provided in Embodiment 1, However, the material and size of the sound-absorbing and insulating composite 8 are different from those of the sound-absorbing and insulating composite 8 in Embodiment 1.

[0048] In this embodiment, both the rigid base layer 3 and the rigid constrained layer 1 are steel plates with a thickness of 1.5 mm, and the elastic damping layer 2 is a butyl rubber plate with a thickness of 5 mm; the micro-perforated plate 7 has a thickness of 1 mm and a hole diameter of 0.83 mm, steel micro-perforated plate with a hole spacing of 12.5 mm; the fiber material layer is a glass wool layer, and the surface density of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com