Material performance test machine with nitriding function

A technology of material performance and testing machine, which is applied in the direction of analyzing materials, applying stable tension/pressure to test material strength, strength characteristics, etc., can solve the problems of complicated processing, long time-consuming, uneconomical, etc., to improve processing efficiency, The effect of saving process and time, preventing local overheating and equipment damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Below in conjunction with embodiment the present invention is described in further detail:

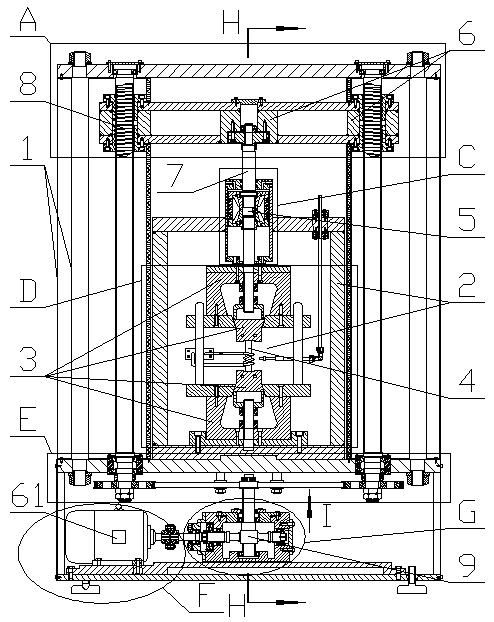

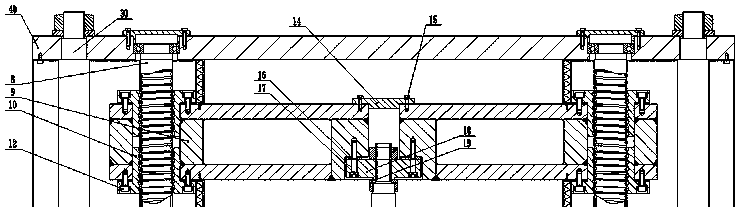

[0041] Such as Figure 1 to Figure 12 As shown, a material performance testing machine with nitriding function includes a frame 1, a nitriding box 2, a moving sealing device 5, a transmission device, and a motor 61. The nitriding box 2 is fixedly connected to the frame, and the moving sealing device 5 communicates with the nitriding box 2, and the nitriding box 2 includes the working fixture 3, the heating coil 2a, and the nitrogen gas nozzle 2b, which are arranged inside the nitriding box 2 to clamp the two ends of the workpiece 4, and the heating coil 2a extends to the nitriding box 2 Inside and around the workpiece 4, the nitrogen nozzle 2b extends into the nitriding box 2, and the working fixture 3 is connected with a power mechanism that drives the working fixture to stretch or compress the workpiece 4.

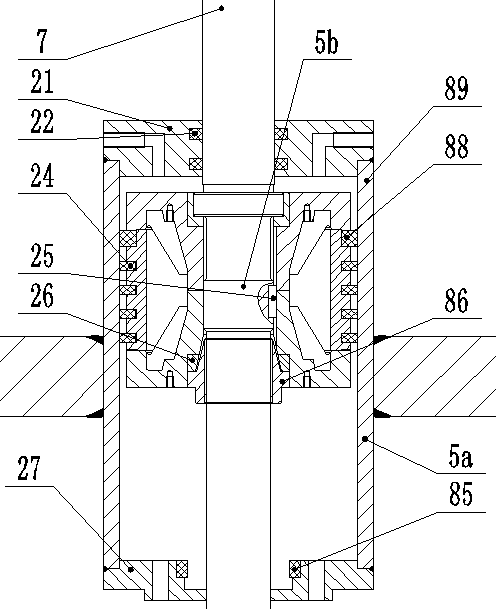

[0042] Such as image 3 As shown, the moving sealing device 5 inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com