Sealing structure of air pre-heater, rotary air pre-heater and boiler

A sealing structure and air preheater technology, which is applied to the sealing of engines, combustion methods, indirect carbon dioxide emission reduction, etc., can solve the problem that it is difficult for seals to accurately reach the best position, the sealing effect of air preheater seals is poor, and the elasticity of elastic parts It is difficult to control the amount of deformation, etc., to achieve the effect of accurate spatial position and spatial attitude, improved sealing effect, and accurate adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

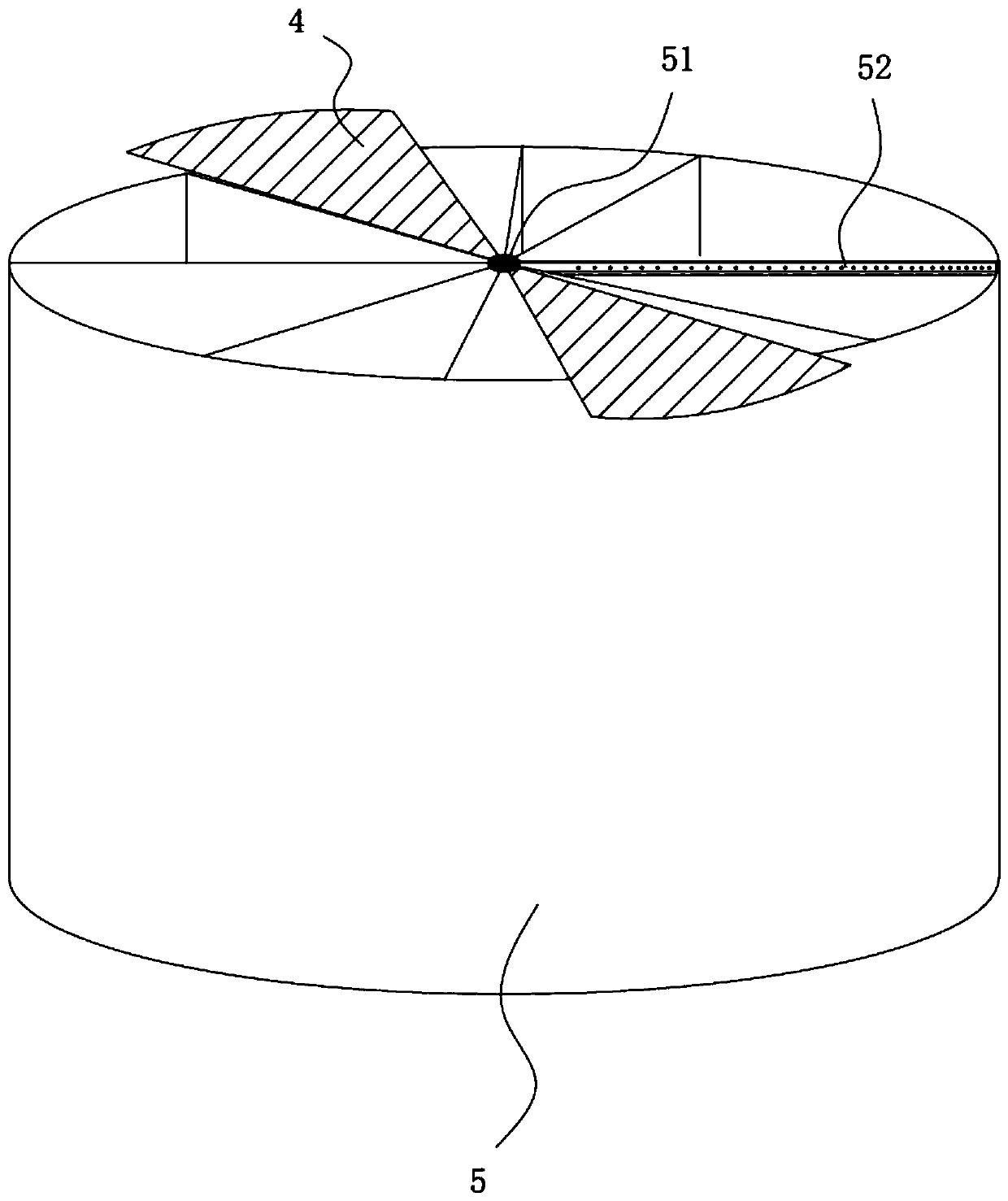

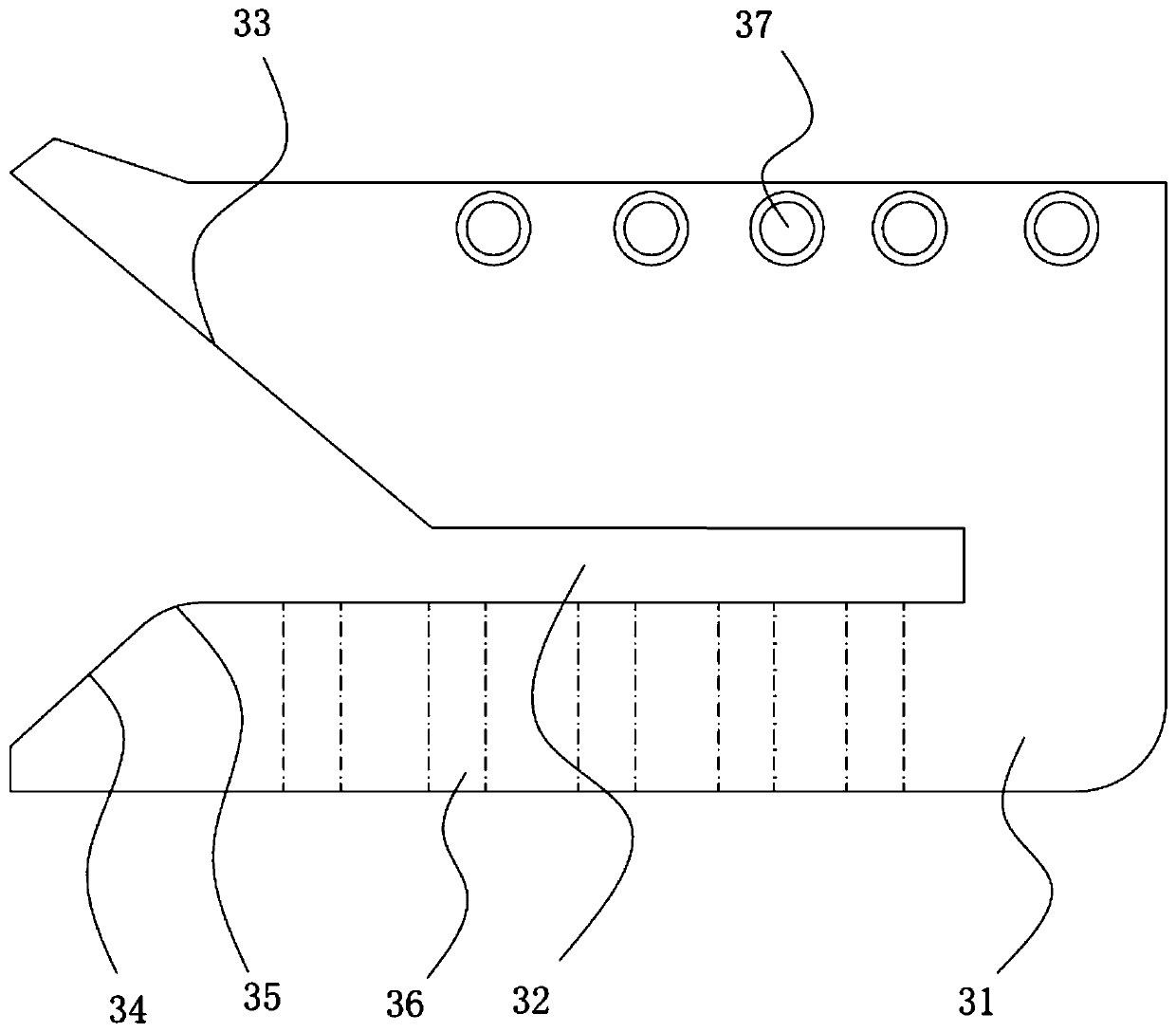

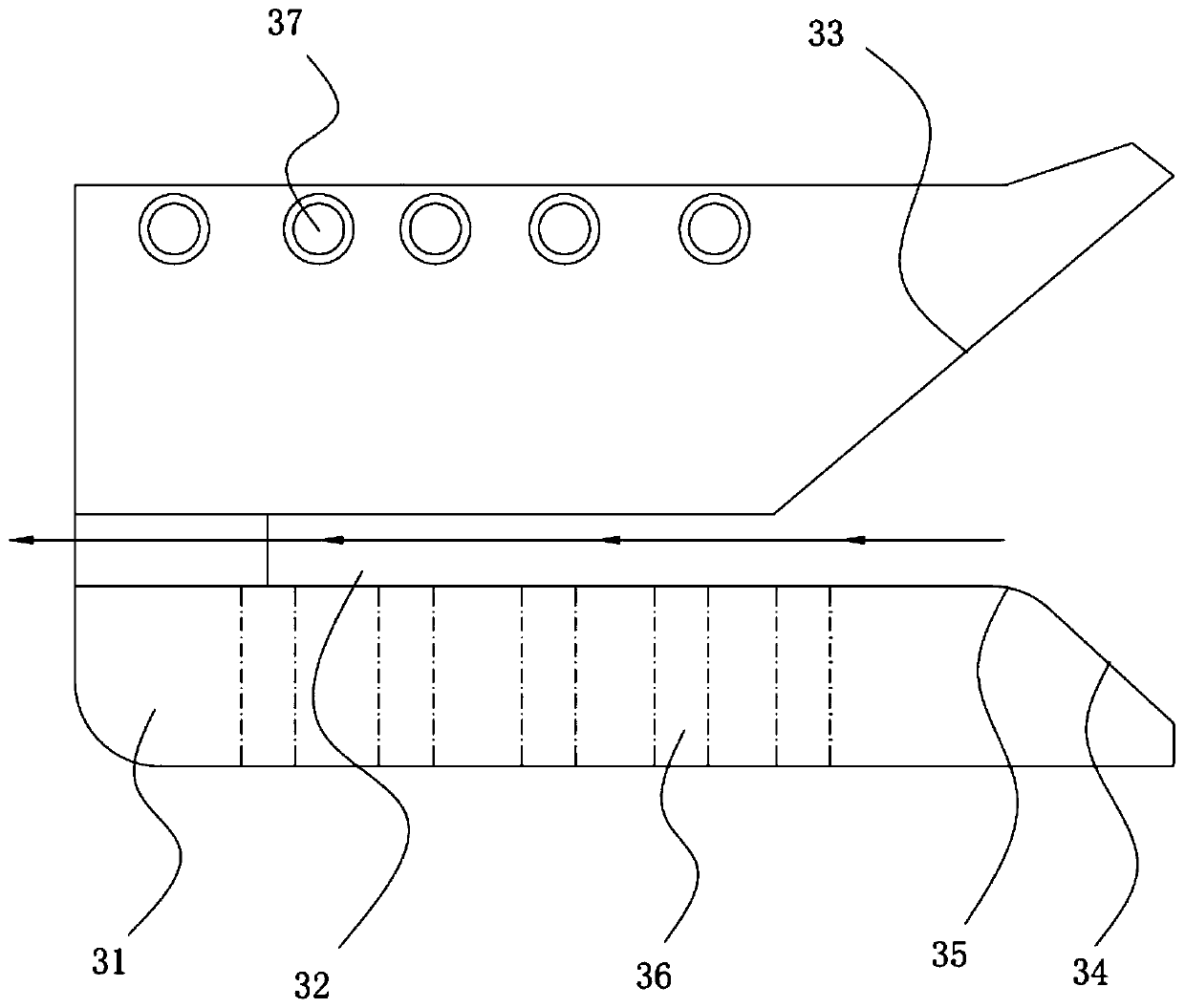

[0033] The embodiment discloses an air preheater sealing structure, a rotary air preheater including the air preheater sealing structure, and a boiler including the rotary air preheater. like Figure 1 to Figure 6 As shown, the rotary air preheater includes a fan plate 4, an air preheater drum 5 and an air preheater sealing structure, the fan plate 4 is arranged on the shaft 51 of the air preheater drum 5, and the fixed bracket of the air preheater sealing structure is fixedly connected On the top or bottom of the air preheater drum 5 , the positioner of the air preheater sealing structure is fixedly connected to the fan plate 4 . The air preheater drum 5 is provided with a fixed bracket mounting position 52, and the fixed bracket mounting position 52 is provided with a plurality of mounting holes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com