Composite fabric edge closing process

A process and fabric technology, which is applied in the field of composite fabric edge finishing technology, can solve the problems of easy wool adjustment, poor skin-adhesion, and yarn take-off, etc., and achieve the effect of reasonable design, good use effect, beautiful and comfortable appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A composite fabric trimming process, the specific steps are as follows:

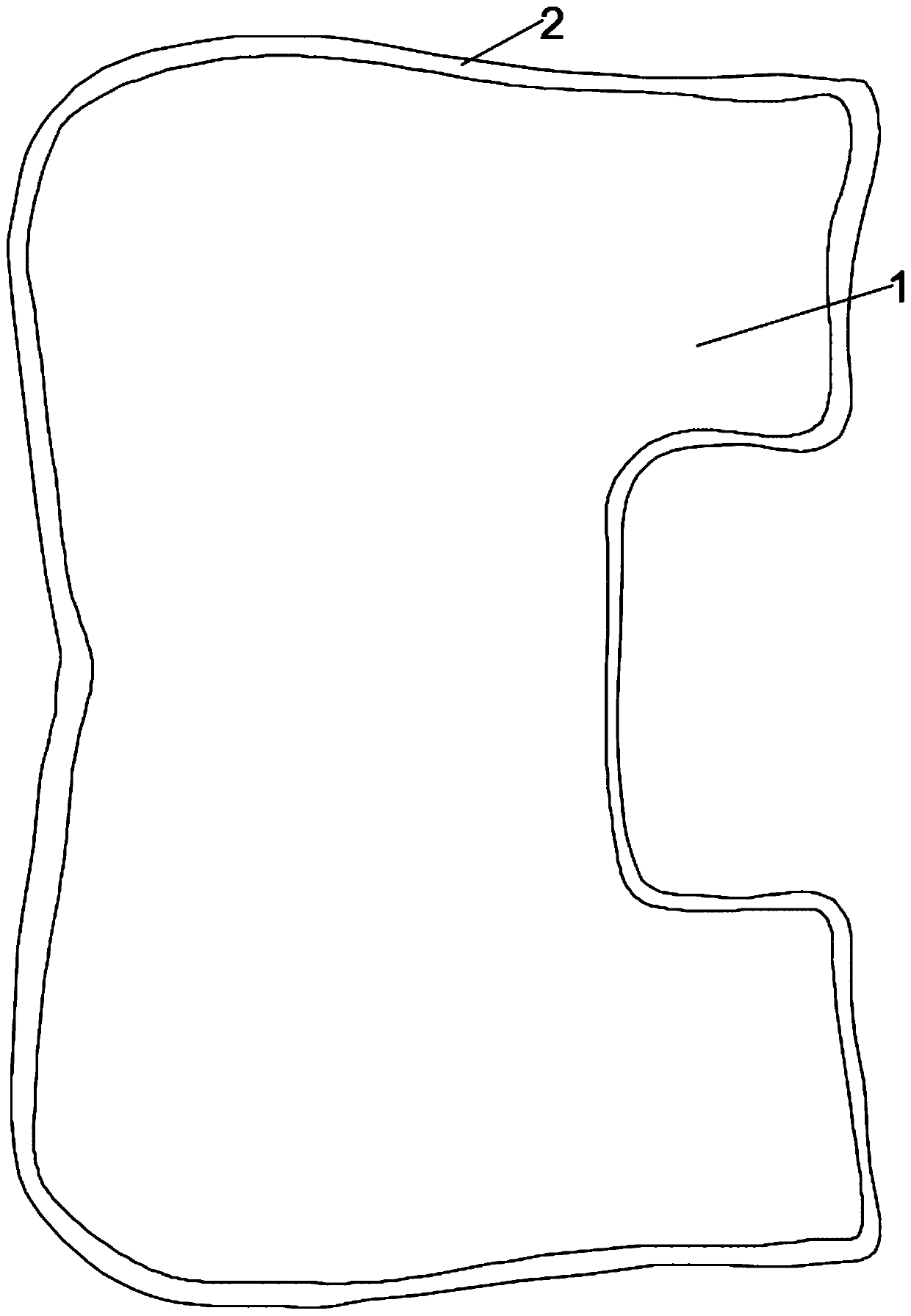

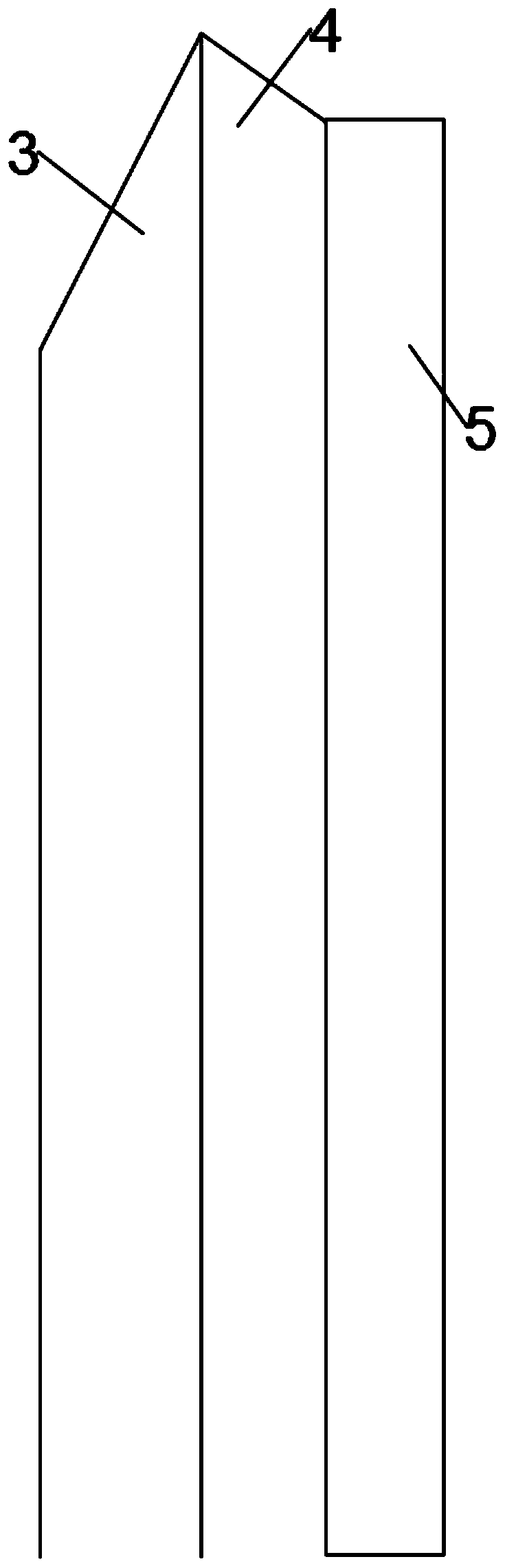

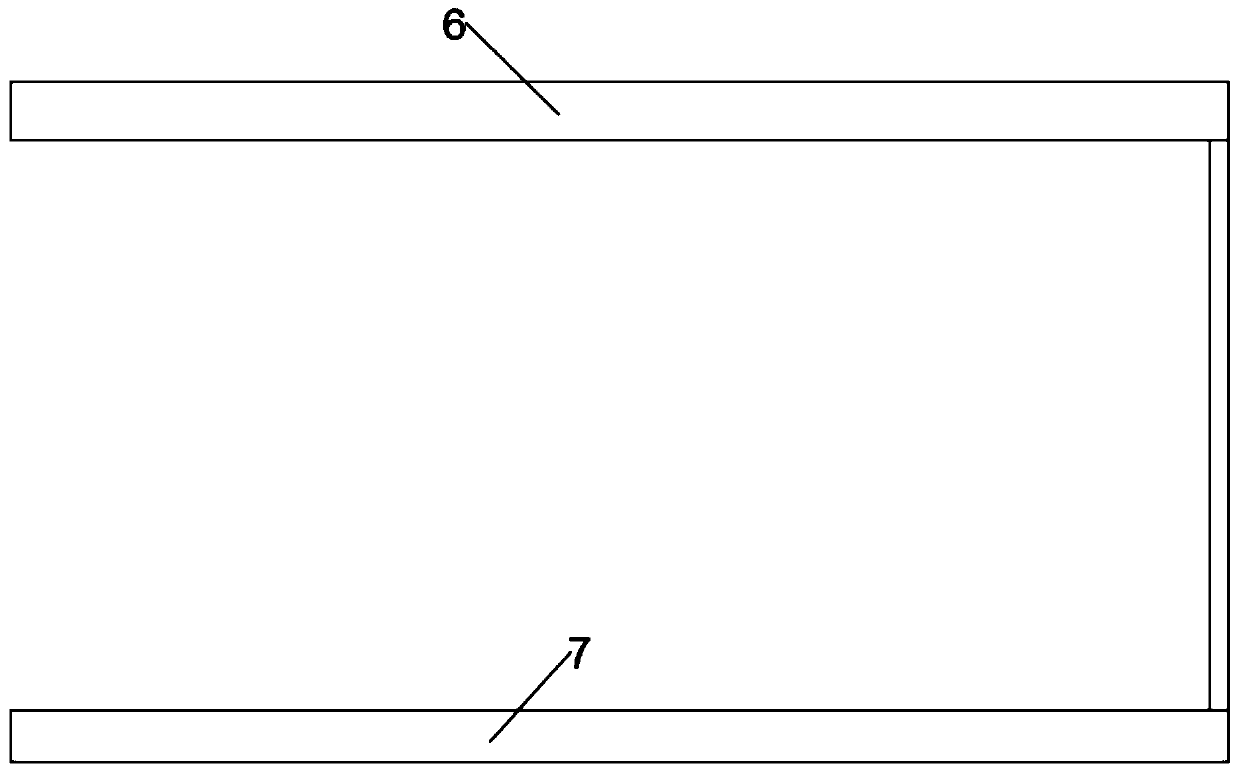

[0029] Step 1: When the clothing 5 adopts the double-sided laminated OK black cloth with a thickness of 3.5mm, a mold with forming and cutting functions is made according to the required shape. The mold includes the mold body 1 and the cutting edge 2, surrounded by the cutting edge 2 Mold body 1, cutting edge 2 is provided with a knife edge, the angle of the main cutting edge 3 is 32 degrees, the angle of the negative cutting edge 4 is 40 degrees, the width of the die line is 0.5mm, and the height from the negative cutting edge 4 is 0.6 mm;

[0030] Step 2: Heat the mold to 148 degrees Celsius to melt 5 sides of the garment;

[0031] Step 3: The setting time is 29 seconds and the pressure is 1.4 tons;

[0032] Step 4: Cool the formed garment 5 naturally.

Embodiment 2

[0034] A composite fabric trimming process, the specific steps are as follows:

[0035] Step 1: When the clothing 5 adopts the double-sided laminated OK black cloth with a thickness of 8.1mm, a mold with forming and cutting functions is made according to the required shape. The mold includes the mold body 1 and the cutting edge 2, surrounded by the cutting edge 2 Mold body 1, cutting edge 2 is provided with a knife edge, the angle of the main edge 3 is 35 degrees, the angle of the negative edge 4 is 40 degrees, the width of the die line is 0.65mm, and the height from the negative edge 4 is 1.1 mm;

[0036] Step 2: Heat the mold to 155 degrees Celsius to melt 5 sides of the garment;

[0037] Step 3: The setting time is 38 seconds and the pressure is 3 tons;

[0038] Step 4: Cool the formed garment 5 naturally.

Embodiment 3

[0040] A composite fabric trimming process, the specific steps are as follows:

[0041] Step 1: When the apparel 5 uses EVA composite cloth with a thickness of 5.2mm, a mold with a forming and cutting function is made according to the required shape. The mold includes a mold body 1 and a cutting edge 2. The cutting edge 2 surrounds the mold body 1, and the cutting knife The edge 2 is provided with a knife edge, the angle of the main edge 3 is 25 degrees, the angle of the negative edge 4 is 45 degrees, the width of the die line is 0.5mm, and the height from the negative edge 4 is 0.75mm;

[0042] Step two, heating the mold to 116 degrees Celsius for 60 seconds to melt 5 sides of the garment;

[0043] Step 3: The setting time is 33 seconds and the pressure is 27 tons;

[0044] Step 4: Cool the formed garment 5 naturally.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com