Method for utilizing high-manganese molten iron to smelt ultra-low-manganese steel

A technology of ultra-low manganese steel and molten iron, applied in the field of iron and steel metallurgy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

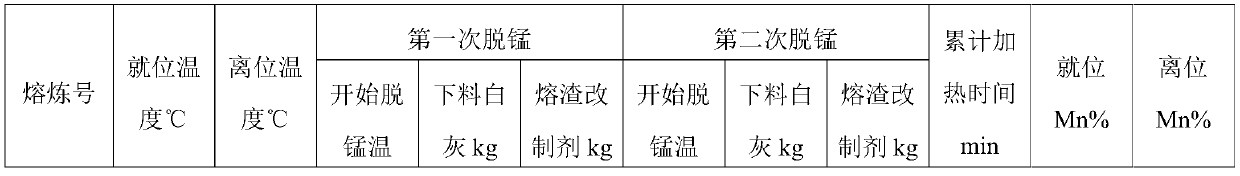

[0038]Using molten iron with a manganese content of 0.423% as the raw material, the double slag smelting process of the converter is used for smelting and demanganization. The low-temperature tapping of the converter link creates better thermodynamic conditions for further demanganization. The in-place temperature of the LF furnace is 1529°C. The Mn content in bit molten steel is 0.055%. During the LF smelting and refining process, 4269kg of lime and 329kg of modified formulations were added, and the cumulative heating was 31 minutes. The manganese content was 0.0165% when it was off-site. The specific parameters are shown in Table 1 below.

Embodiment 2

[0040] Using molten iron with a manganese content of 0.416% as the raw material, it is smelted using the double slag smelting process of the converter, and the steel is tapped at a low temperature in the converter link to create better thermodynamic conditions for further demanganization. The Mn content in molten steel is 0.049%. During the LF smelting and refining process, add 4442kg of lime, 346kg of reforming agent, heat for 33 minutes, and the manganese content is 0.0146% when off-site. The specific parameters are shown in Table 1 below.

Embodiment 3

[0042] Using molten iron with a manganese content of 0.457% as the raw material, the double slag smelting process of the converter is used for smelting, and the steel is tapped at a low temperature in the converter link to create better thermodynamic conditions for further demanganization. The Mn content in molten steel is 0.053%. During the LF smelting and refining process, add 3878kg of lime, 286kg of reforming agent, heat for 26 minutes, and the manganese content is 0.0136% when it is off-site. The specific parameters are shown in Table 1 below.

[0043] In the above three embodiments, the manganese content of molten iron in the furnace all exceeds 0.40%, and the manganese content cannot be reduced to below 0.05% after demanganization by the converter. After further demanganization by the LF furnace, the manganese content of the molten steel further decreases, and finally reaches the smelting standard, which is lower than 0.02%. The specific process parameters and process e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com