Coiled core pipe with uniform and rough surface

A technology with uniform surface and core tube, applied in the field of core tube, can solve the problems of copper and aluminum foil wrinkle, poor primer and other problems, achieve the effect of uniform thickness, good starting primer, and improved quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

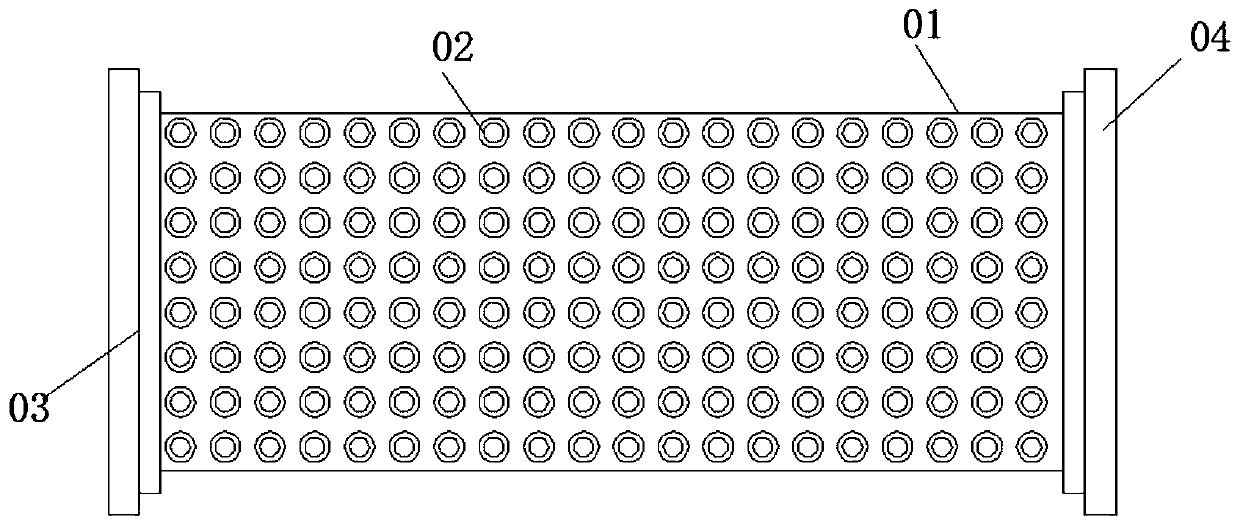

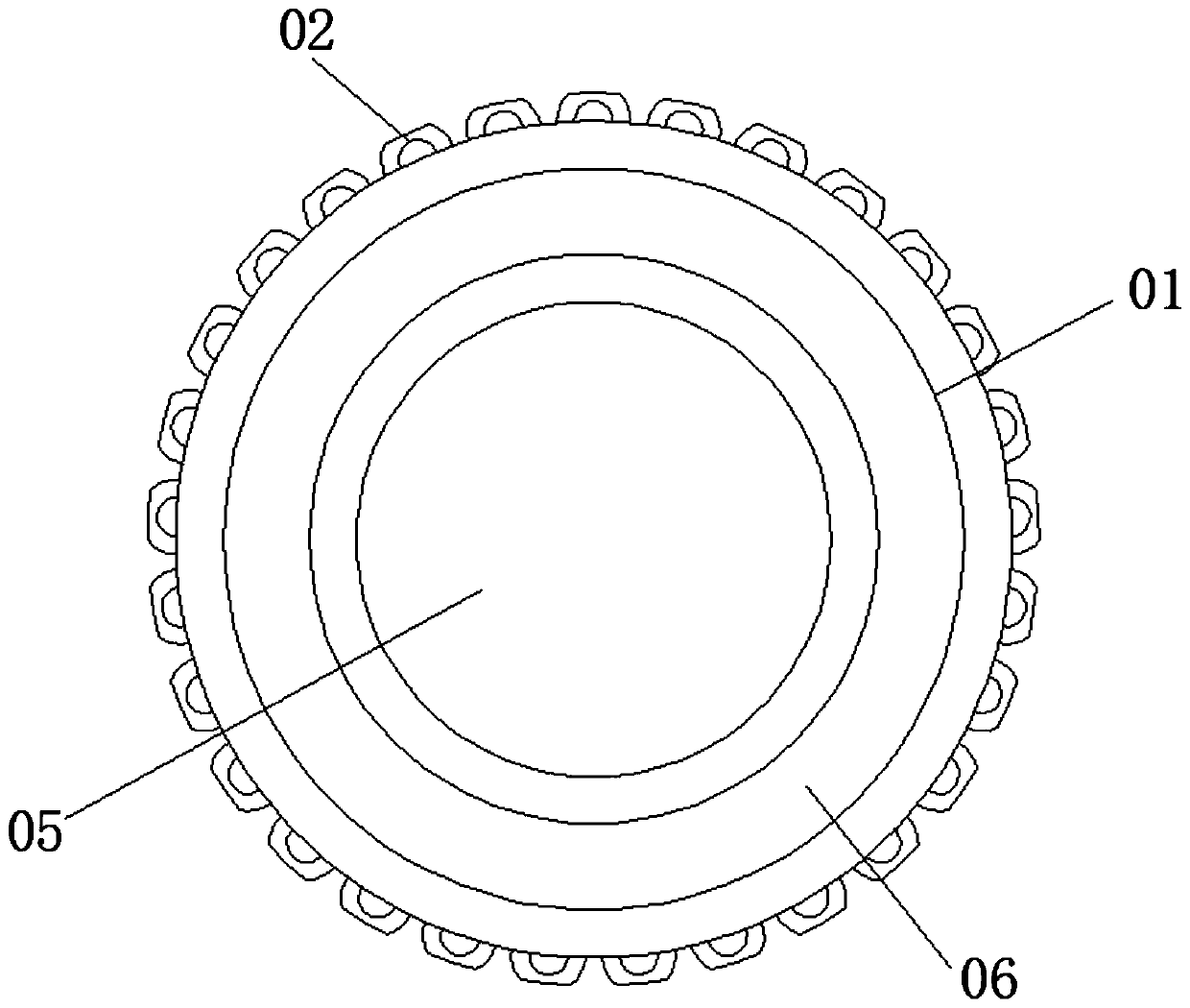

[0026] see Figure 5 , the diameter range of the spray particle 02 is 2-8 mm. At this time, when the copper and aluminum foil with a thickness of less than 6 mm is retracted, compared with the unset spray particle 02, the copper and aluminum foil has just touched the spray particle 02. When the friction coefficient is low, it is conducive to the straightening and leveling of the copper and aluminum foil, and it is helpful for the starting of the copper and aluminum foil to make a bottom.

Embodiment 2

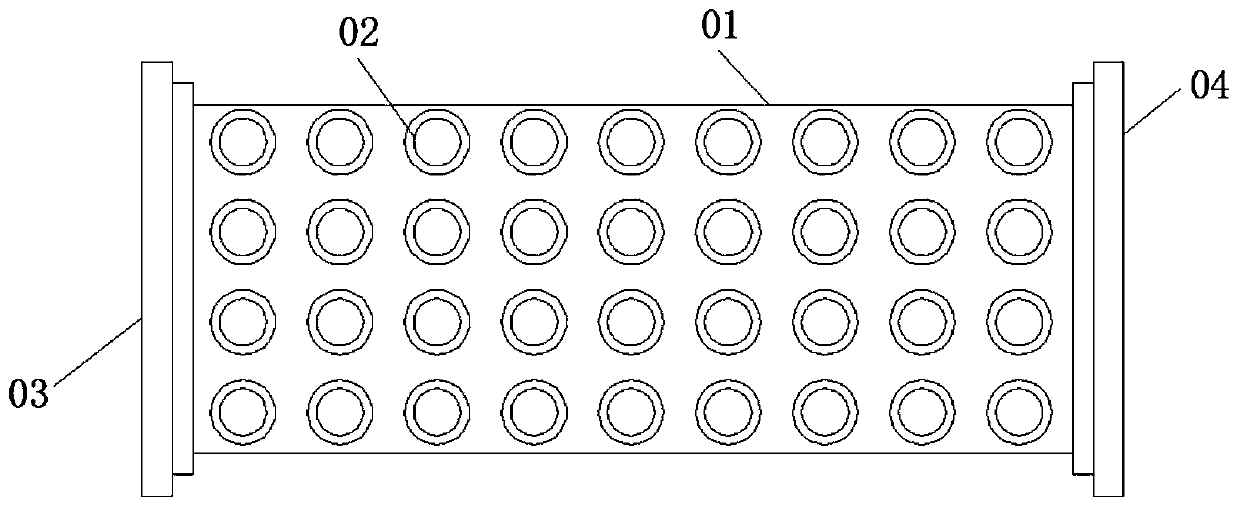

[0028] see Image 6 , the diameter range of the spray particle 02 is 9-15 um, at this time, when the copper and aluminum foil with a thickness of more than 6 um is retracted, due to the large distance between the spray particles 02, a gap is formed, and there is an exhaust passage. As a result, the gas can be discharged as soon as possible when the copper and aluminum foil is turned, and the wrinkle and bulging phenomenon of the copper and aluminum foil is greatly reduced. Compared with the case where the spray particles 02 are not installed, the copper and aluminum foil is not tightly attached to the rotating cylinder 01. The frictional force between the copper aluminum foil and the flat rough surface formed by spraying particles 02 on the surface of the rotating cylinder 01 is increased, which can prevent the copper and aluminum foil from sliding on the rotating cylinder 01 after being rolled.

[0029] When using the present invention:

[0030] When in use, first select the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com