Drive braking system of rack-and-pinion vehicle

A technology of braking system and rack car, which is applied in the direction of railway braking system, brake with brake parts, transmission device driven by electric motor, etc., and can solve the problem that the brake drum cannot brake around the rack wheel and there are many parts , The structure of the drum brake device is complicated, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

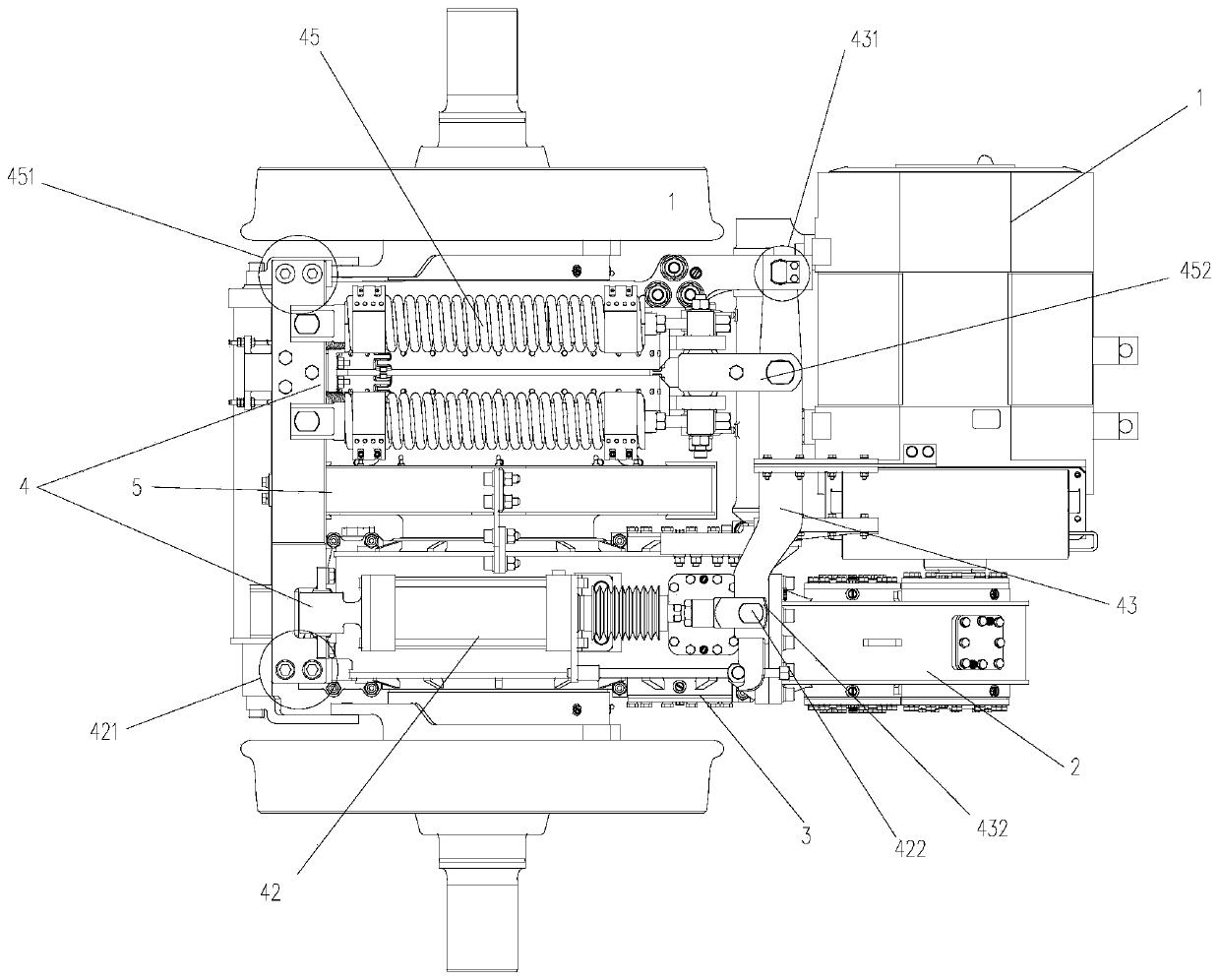

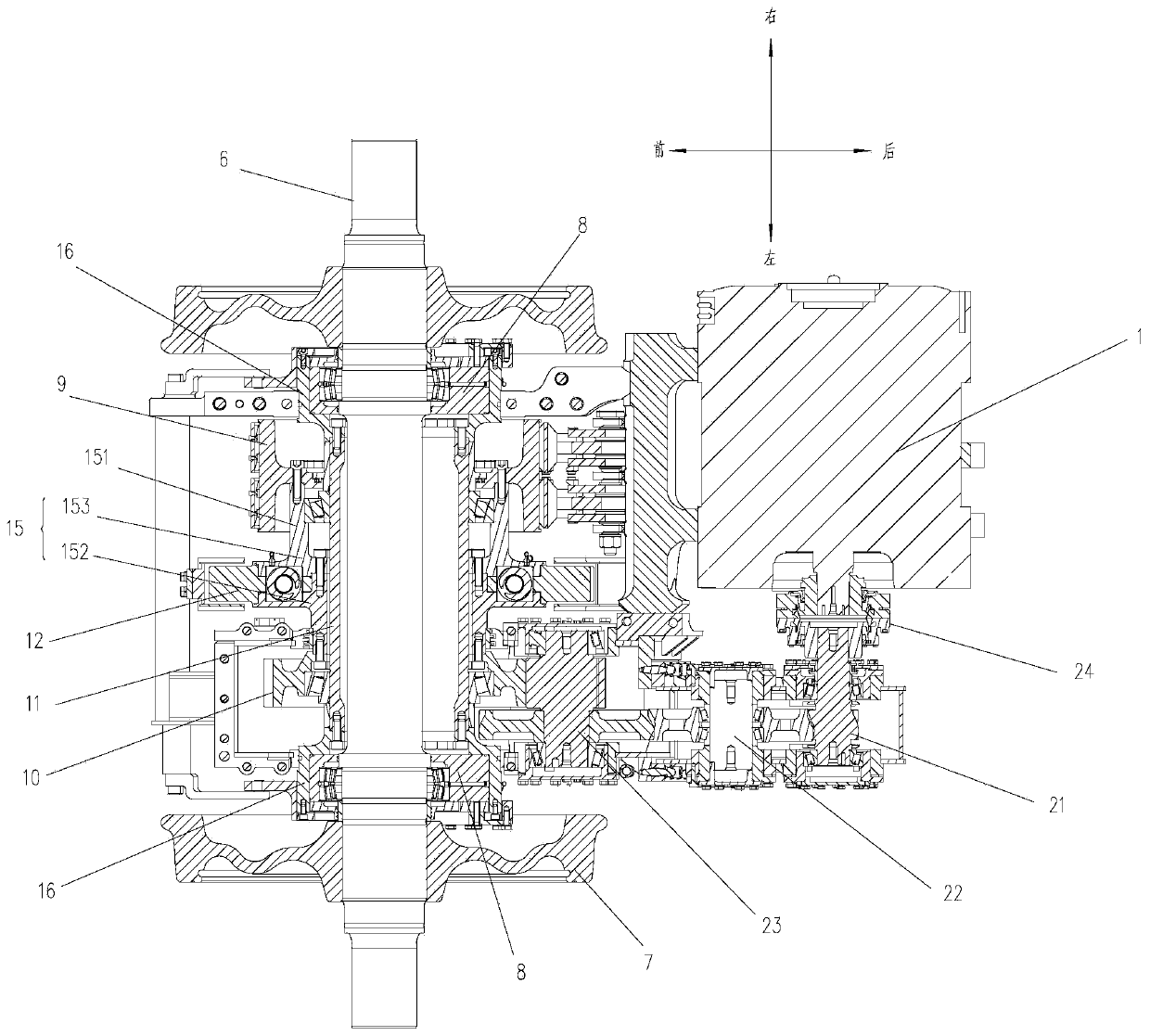

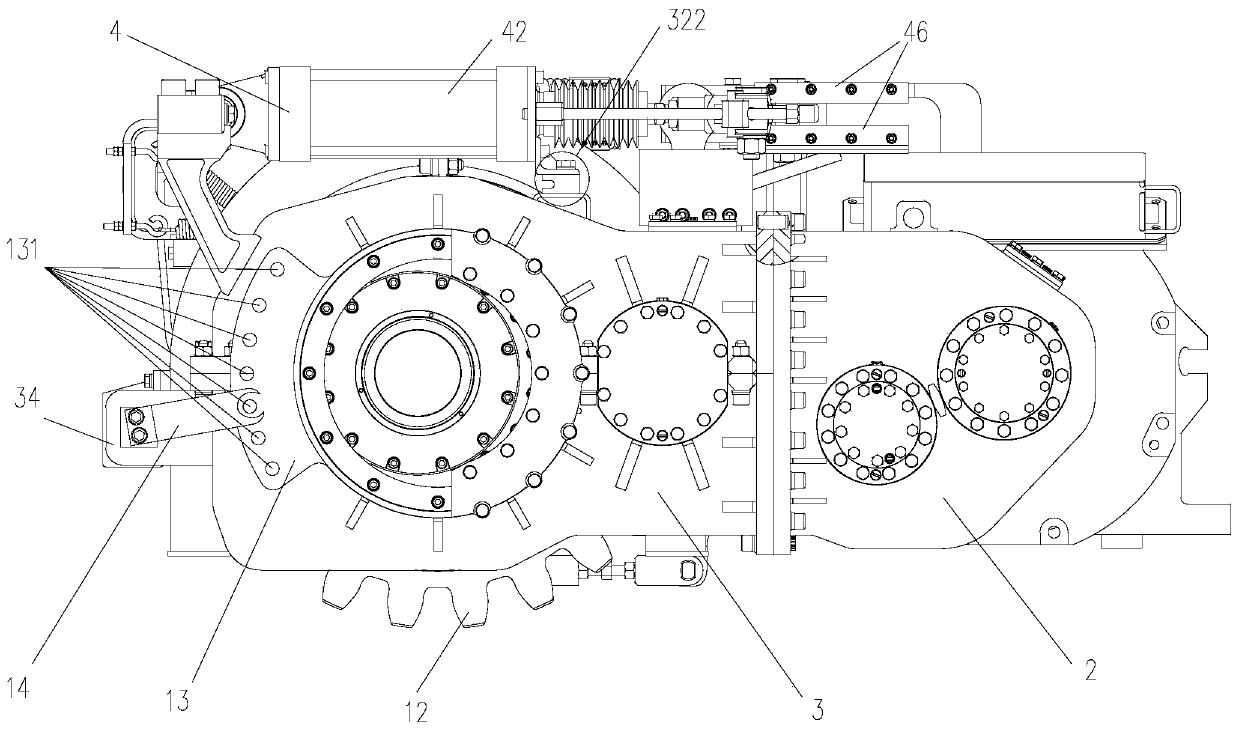

[0039] Such as Figure 1-5 As shown, the rack car driving and braking device in this embodiment includes a gear box 3 , and an axle bridge integrated on the gear box 3 , a rack wheel 12 , a rack wheel base 15 , a driving device and a braking device 4 .

[0040] For convenience, refer to figure 2 and Figure 6 , in this embodiment, the axial direction of the axle is taken as the left-right direction, and the direction perpendicular to the axial direction of the axle is taken as the front-rear direction for illustration.

[0041] Such as Figure 6 and Figure 7 As shown, the gear box for rack vehicles in this embodiment includes a gear box body 32 for installation with the axle bridge of the rack vehicle, and a fixing seat on the right side of the gear box body 32 that is arranged in parallel with the gear box body 32 33. The active gearbox mounting seat 35 located at the rear end of the gearbox body 32, the motor mounting seat 31 connected to the right end of the active ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com