Apparatus for handling and locally fixing flat thermoplastic materials

A local, equipment technology, applied in the field of manipulating instruments, to achieve the effects of small space requirements, low gravity, and high laydown accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

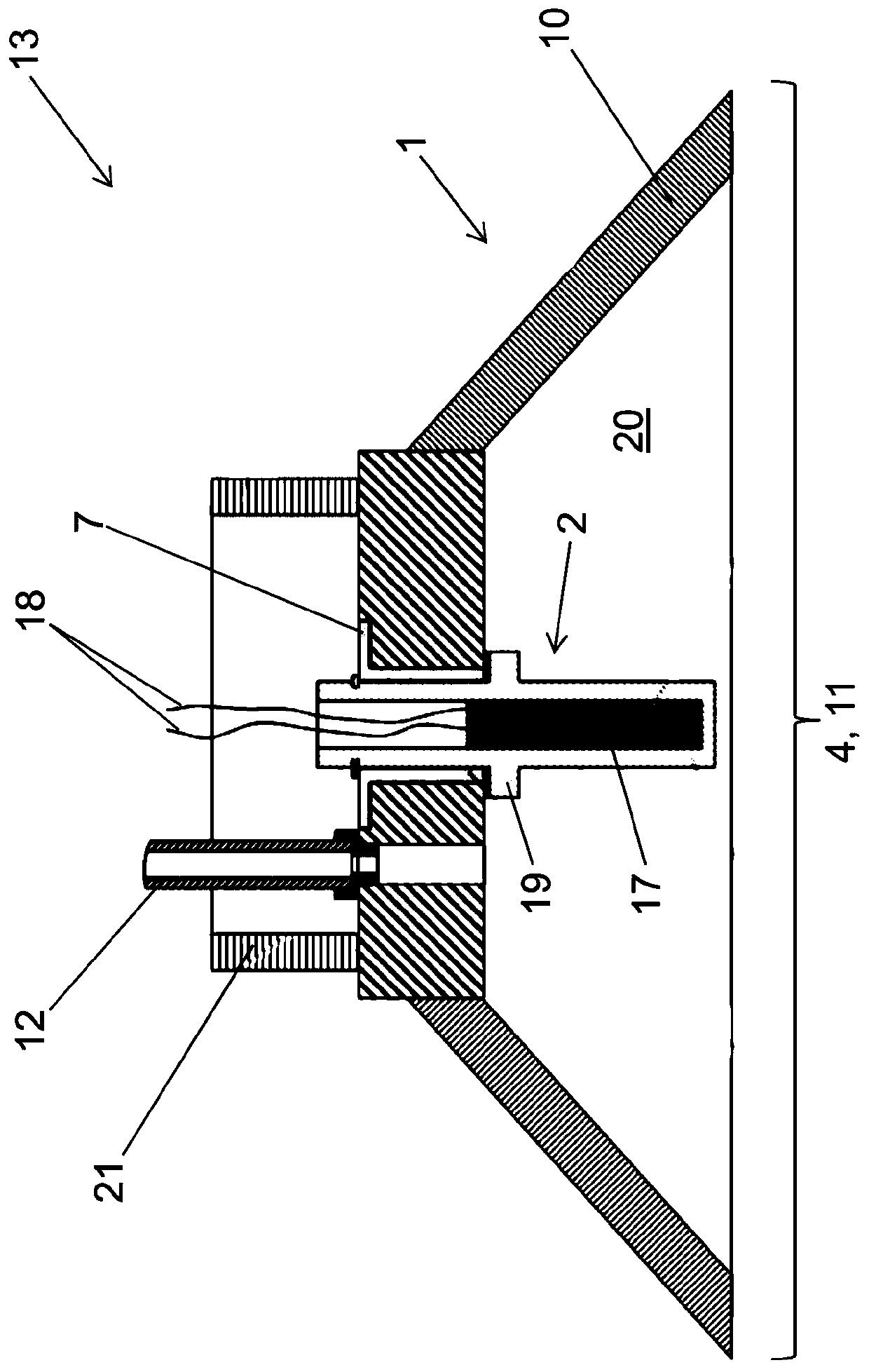

[0049] Figure 1a A first embodiment of a device 13 according to the invention for manipulating and locally fixing planar thermoplastic material 3 is shown. In this case, the device has a holding device 1 , which is designed as a vacuum gripper 10 , and a heating element 2 . Here, the heating element 2 is arranged in the central region of the vacuum suction gripper 10 . The heating element 2 itself is designed as an electrical heater 17 , which can be supplied with energy via a cable 18 . The electric heater 17 is supported inside a receiving sleeve 19 which is connected to the holding device 1 via the insulating layer 7 . The holding device 1 forms an interior space 20 which can be evacuated by means of the suction device 12 in order to hold the planar thermoplastic material 3 in the suction region 11 or in the holding region 4 .

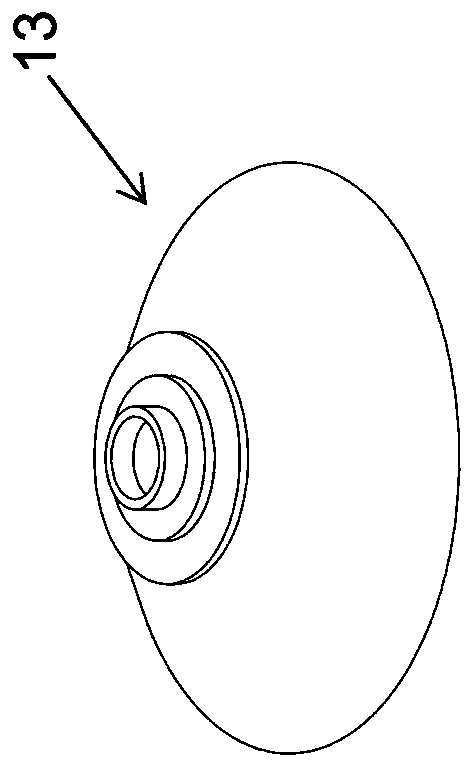

[0050] exist Figure 1b shown in Figure 1a Isometric view of device 13 in .

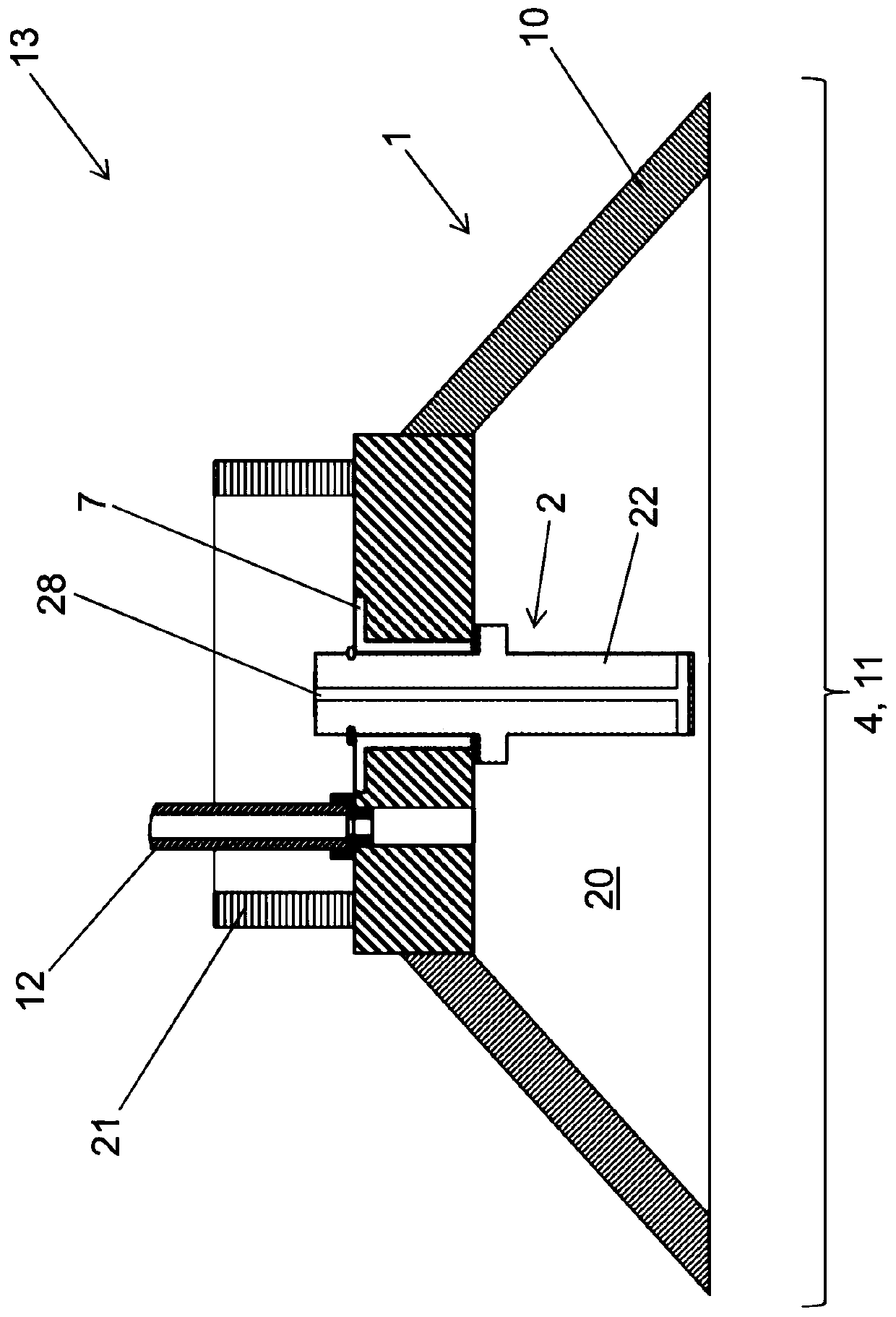

[0051] figure 2 A second embodiment variant of the device 13 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com