Complex curved surface polishing device

A complex surface, grinding and polishing technology, used in grinding/polishing safety devices, grinding drive devices, grinding/polishing equipment, etc., can solve problems such as difficult control, weakening, and unstable control, and achieve high grinding and polishing accuracy. , Good soft control, good control stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

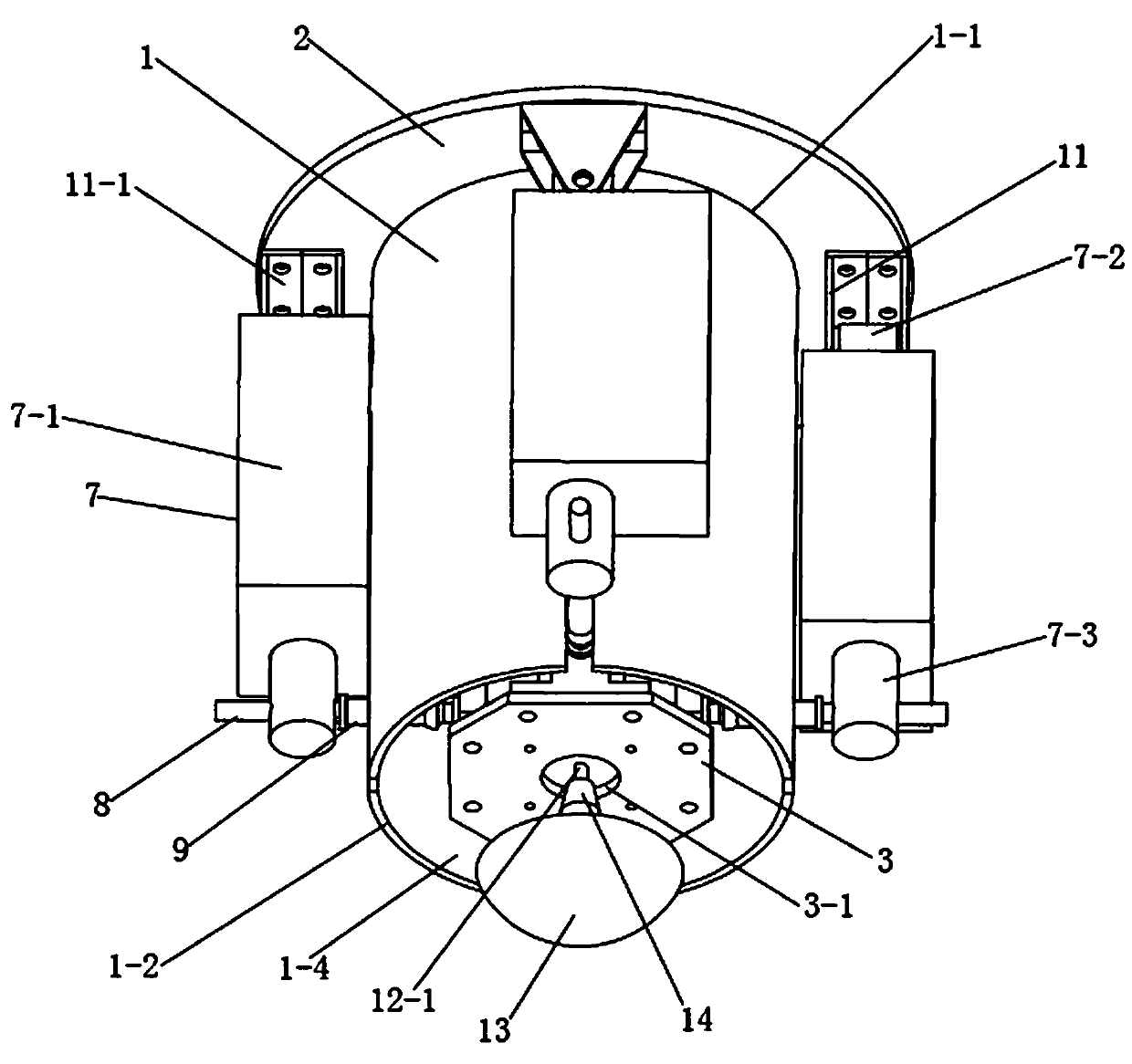

[0030] like Figure 1-3 As shown, a complex curved surface polishing device provided in this embodiment includes:

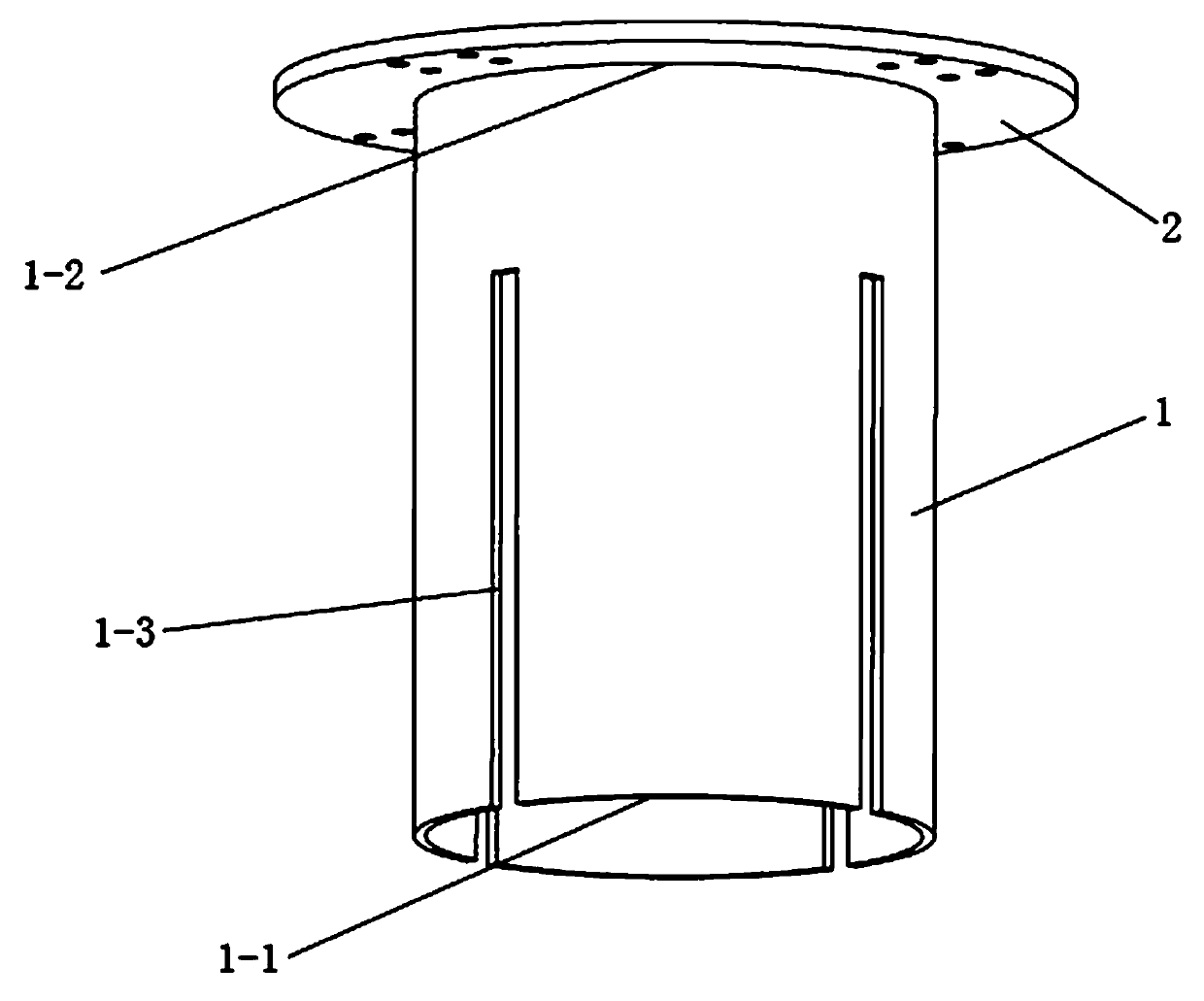

[0031] A circular tubular base 1 is provided with four grooves 1-3 evenly distributed around the center line on the side wall,

[0032] The four tanks 1-3 all extend from the first end 1-1 of the base 1 to the second end 1-2; a flange 2 is arranged on the outside of the second end 1-2, and the flange 2 directly welded to the second end 1-2, and the center lines of the flange 2 and the base 1 coincide;

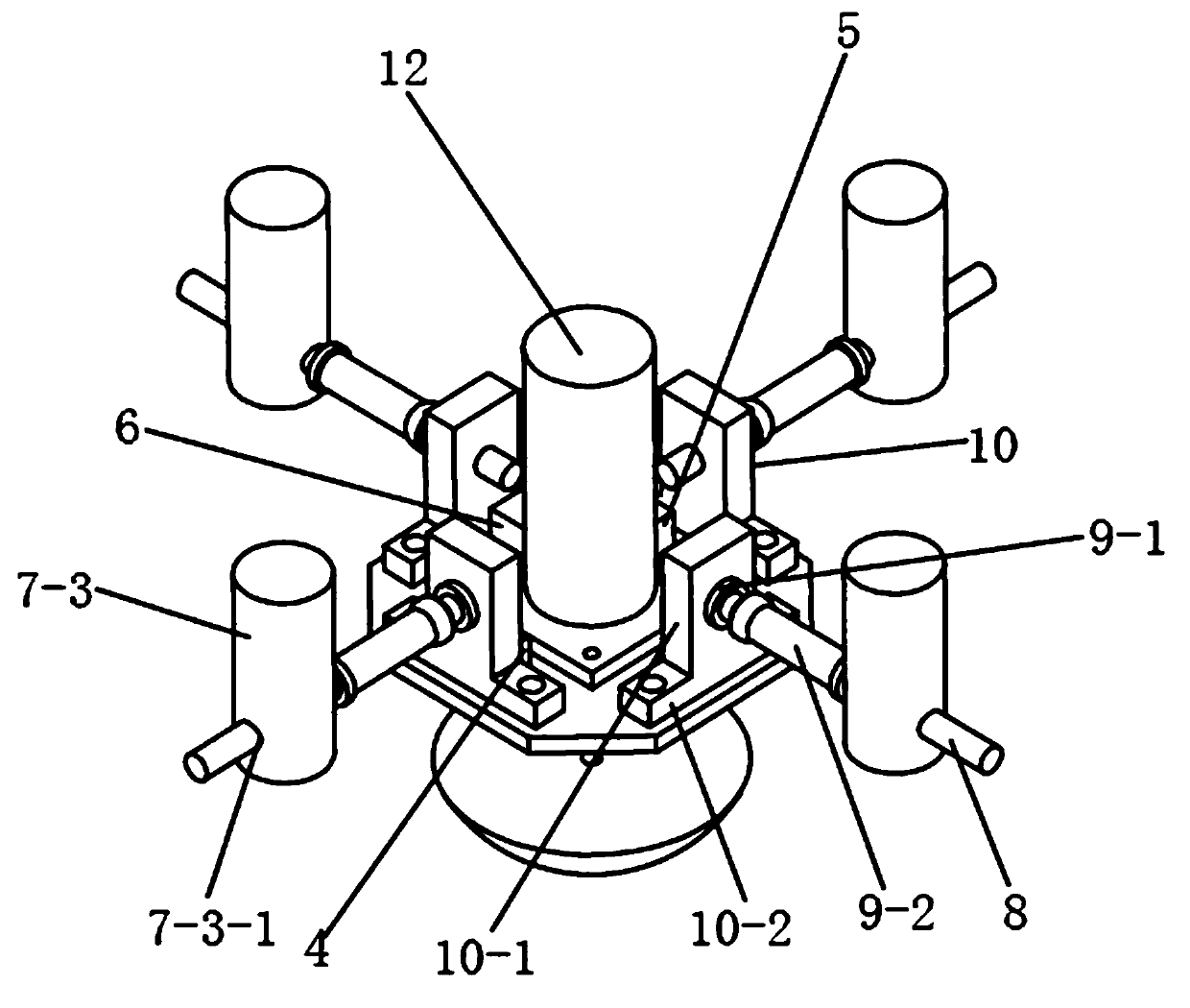

[0033] A force position control device, including a substrate 3, a multidimensional force sensor 4, an inclination sensor 5, a controller 6, four servo electric push rods 7, four connecting rods 8, four ball joint bearings 9 and four A ball joint bearing seat 10; the center of the base plate 3 is provided with a first through hole 3-1;

[0034] Wherein, the substrate 3 is located on one side of the first end 1-1 of the base 1, and the four ball joint bearing se...

Embodiment 2

[0050] A kind of complex curved surface lapping and polishing device provided in this embodiment, its general structure is consistent with embodiment 1, as Figure 4 As shown, but in this embodiment, the side wall of the base 1 is provided with four installation reserved holes 1-5 uniformly distributed around the center line, and are connected with the fasteners on the four mounting seats 11 one by one. correspond.

[0051] The aforementioned installation reserved holes 1-5 can facilitate the locking and installation of the connecting head 7-2 of the servo electric push rod 7 and the mounting seat 11 through fasteners.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com