High damping titanium-nickel memory alloy/metal layered composite material

A memory alloy and composite material technology, which is applied in the field of titanium-nickel memory alloy/metal layered composite materials, can solve problems such as anisotropy of titanium-nickel memory alloy composite materials, and achieve good mechanical properties, high damping performance, and good mechanics. The effect of damping properties with

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

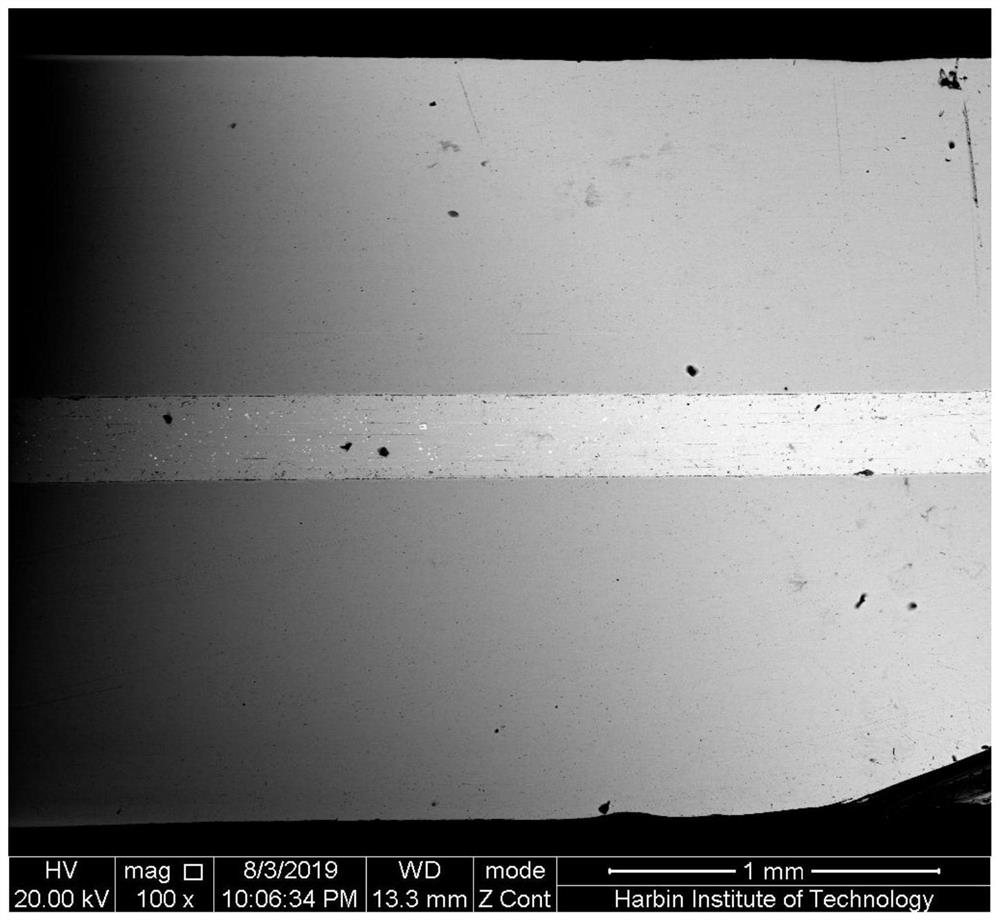

[0019] Embodiment 1: The high-damping titanium-nickel memory alloy / metal layered composite material in this embodiment is composed of several titanium-nickel memory alloy layers and several metal layers, and the titanium-nickel memory alloy layers and metal layers are arranged at intervals;

[0020] The elastic modulus of the metal layer is 1.5 to 7 times that of the titanium-nickel memory alloy;

[0021] The atomic percentage of Ni contained in the titanium-nickel memory alloy layer is 48%-52%.

[0022] The principles and beneficial effects of this embodiment are:

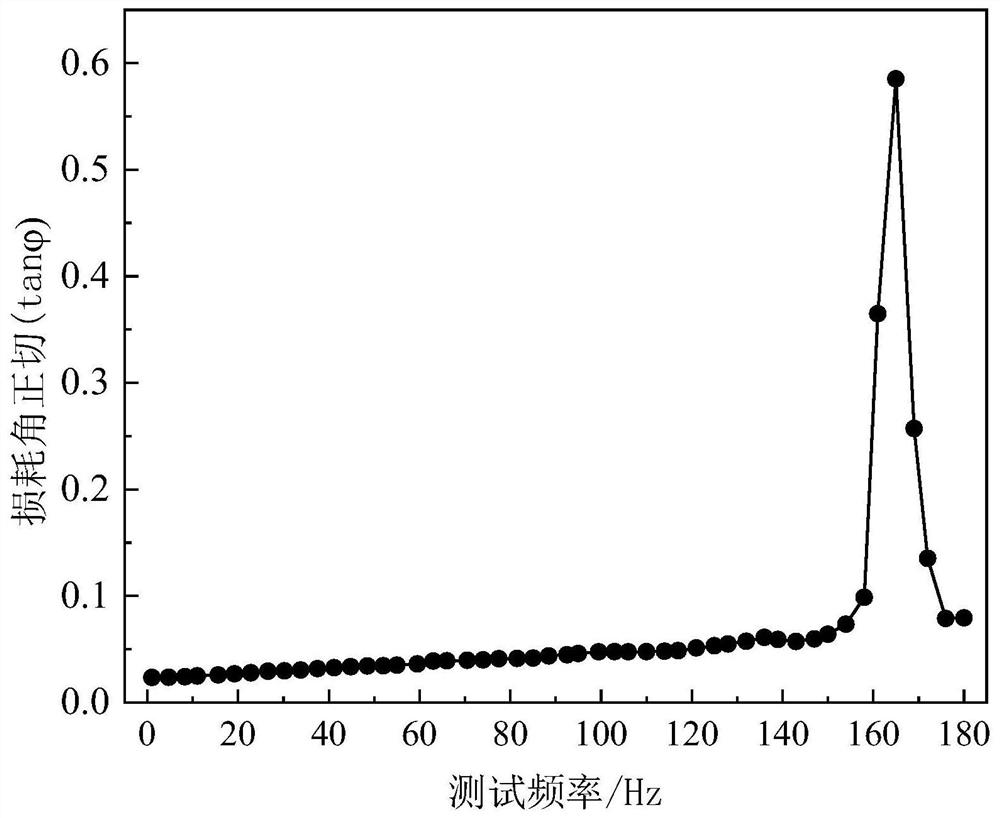

[0023] 1. In the layered composite material of this embodiment, the martensitic state of the titanium-nickel memory alloy layer has a low elastic modulus, about 30GPa; the metal layer has a high elastic modulus, which is 45-210GPa; the titanium-nickel memory alloy layer and the metal layer Overlapping, a high elastic modulus difference is formed between the layers, and when subjected to vibration loads, energy is...

specific Embodiment approach 2

[0029] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the total number of layers of the titanium-nickel memory alloy layer and the metal layer is 2 to 7 layers, including at least one titanium-nickel memory alloy layer and at least one layer metal layer. Other steps and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

[0030] Embodiment 3: This embodiment is different from Embodiment 1 in that: the thickness of the titanium-nickel memory alloy layer and the metal layer are both 0.02-5 mm. Other steps and parameters are the same as those in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com