A kind of fluorite lean ore color separation and quality improvement-tailing pre-selection method

A technology for lean ore and fluorite, which is applied in the field of color separation and quality improvement of fluorite lean ore - tail-throwing pre-selection, which can solve the problems of low operation rate and high labor cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

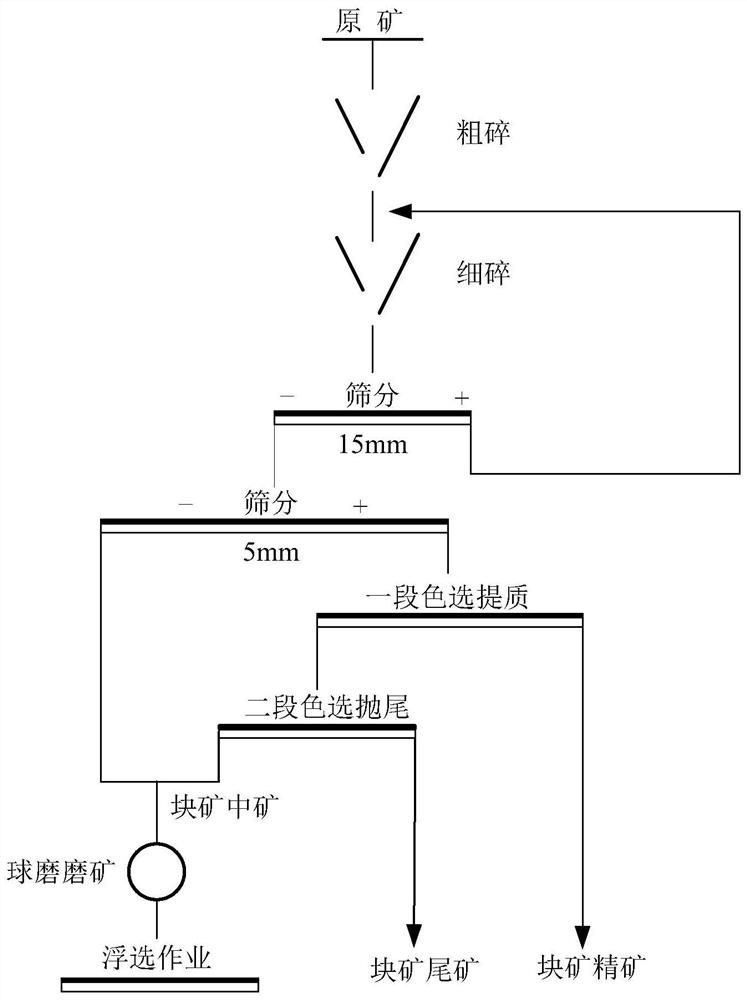

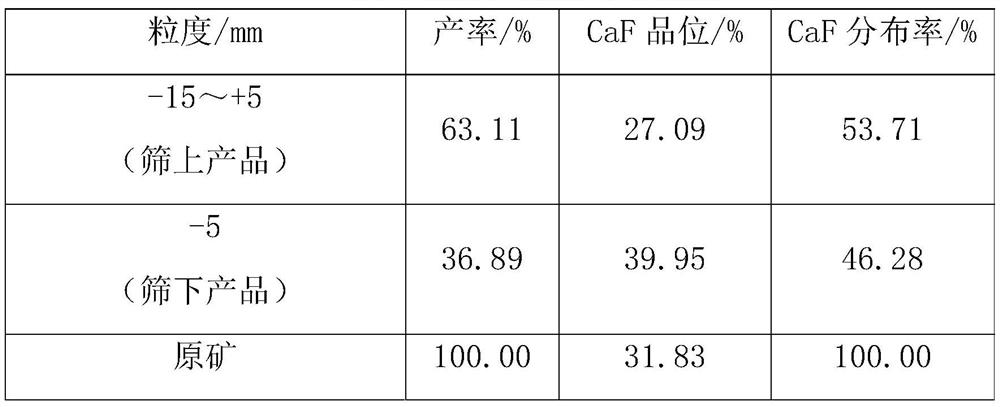

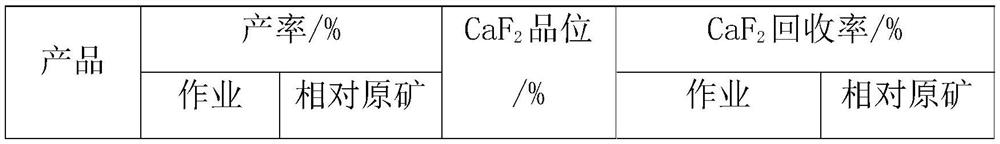

[0025] A low-grade fluorite mine in Hebei, raw ore CaF 2 The grade is 31.83%, and the main gangue minerals are quartz (35.79%), potassium feldspar (14.84%), sericite (5.19%) and clay minerals (2.52%). The gangue minerals in this fluorite mine are mainly silicate minerals, and the content of primary slime is relatively high. After crushing in two stages and one closed circuit, the particle size composition and fluorite distribution of the product are shown in Table 1. See Table 2 for the sorting results of the products on the sieve (-15 ~ +5mm products) after the first stage of color selection for quality improvement - the second stage of color separation for tailing.

[0026] Table 1 Results of distribution rate of broken products

[0027]

[0028] Table 2 Color Sorting and Quality Improvement - Finishing Results

[0029]

[0030]

[0031] It can be seen from Table 1 that due to the presence of a large number of hard silicate minerals, the fluorite is preferentiall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com