A Coarse and Fine Crushing Integrated Medium Coal Wet Crusher

A wet crushing, integrated technology, applied in grain processing and other directions, can solve the problems of over-crushing and crushing efficiency, low equipment processing capacity, and easy blockage of crushing cavity, and achieves low upper particle size limit of crushed products, simple structure, and over-crushing. Phenomenal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The specific embodiment of the present invention is described in further detail below in conjunction with accompanying drawing:

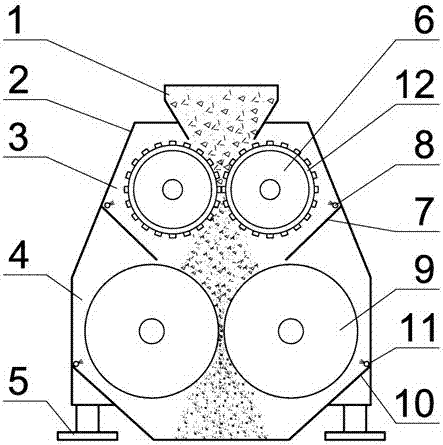

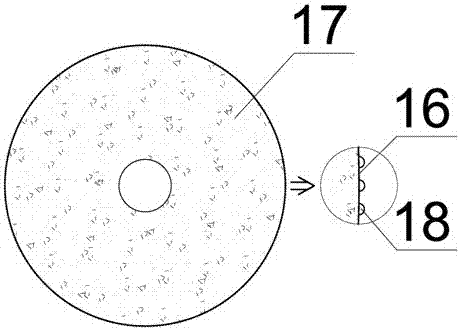

[0012] Such as figure 1 As shown, a coarse and fine crushing integrated medium coal wet crusher of the present invention includes a body shell 2, a feed hopper 1 is provided on the top of the body shell 2, a bracket 5 is provided at the bottom of the body shell 2, and a device is provided inside the body shell 2. The first crushing chamber 3 above and the second crushing chamber 4 arranged below the first crushing chamber 3 are provided with a first collecting hopper 7 between the first crushing chamber 3 and the second crushing chamber 4; wherein the first crushing chamber 3 Located under the feed hopper 1, the first crushing chamber 3 is provided with two sets of knife-ring type first crushing rollers 6, the gap between the two sets of first crushing rollers 6 is between 10mm and 13mm, and the first crushing rollers 6 include the first Smo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com