Two-dimensional layered vermiculite membrane, production and application

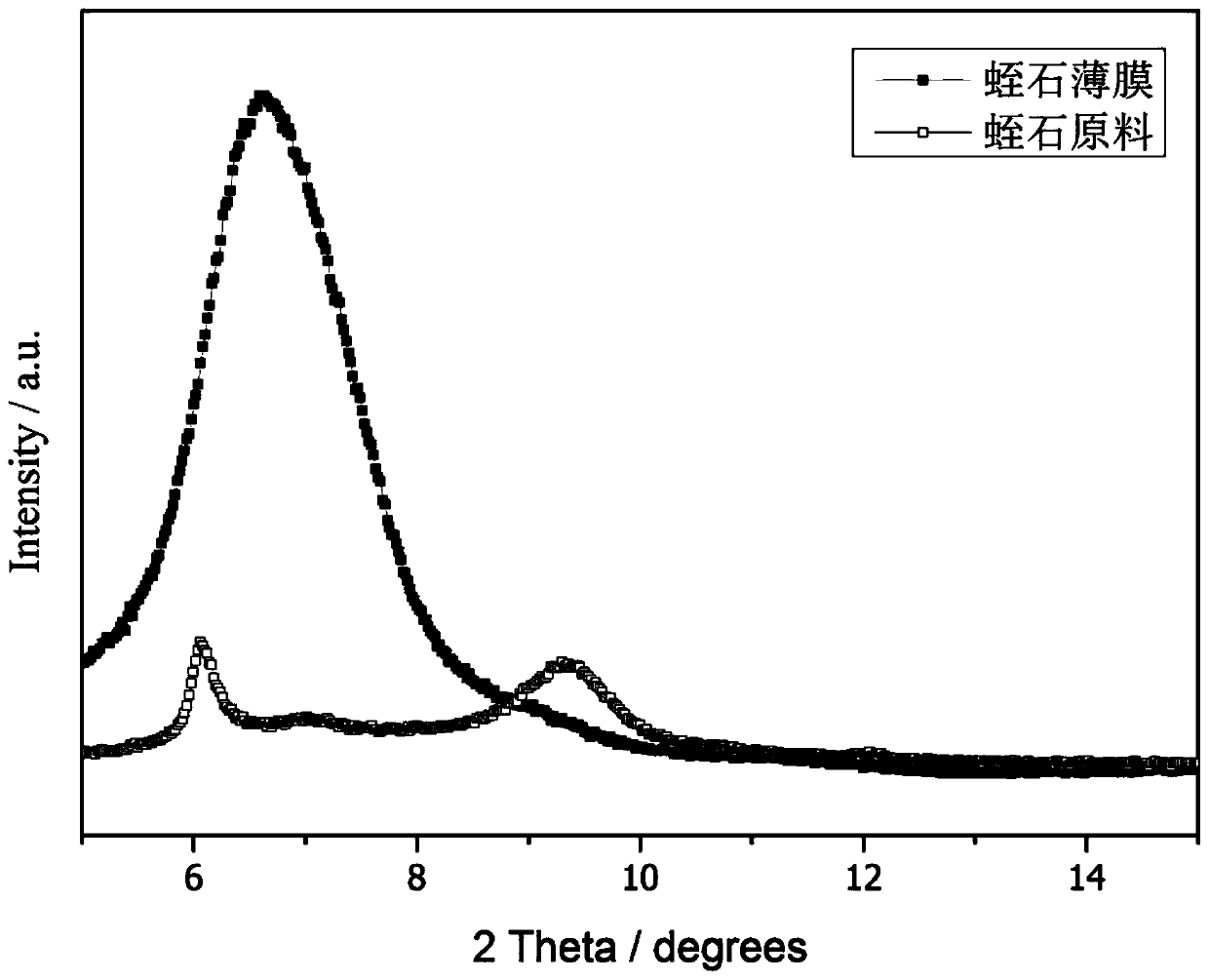

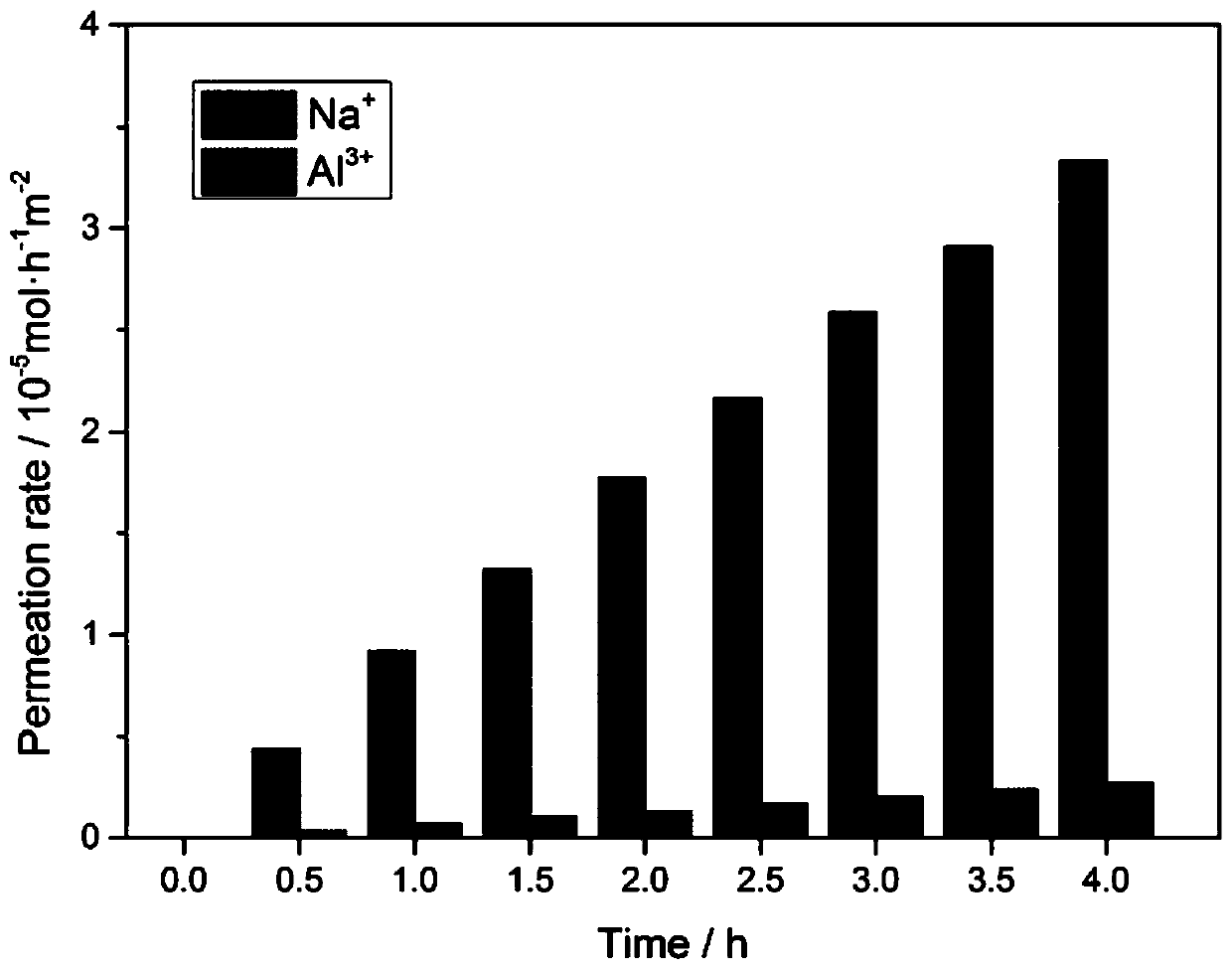

A two-dimensional layered, vermiculite technology, applied in the direction of membrane, membrane technology, semi-permeable membrane separation, etc., can solve the problems of separation membrane structural defects, poor filtration performance, etc., to achieve large size, excellent solvent molecule permeability , the effect of high retention rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Step 1: Add heat-expandable vermiculite particles into lithium chloride solution, and stir magnetically for 24 hours at an oil bath temperature of 120° C., wherein the mass ratio of heat-expandable vermiculite, water, and LiCl is 1:35:3. Then centrifuge and wash until no chloride ions can be detected in the supernatant, and powder A is obtained.

[0032] Step 2: Add powder A powder into 30% hydrogen peroxide solution at a mass ratio of 1:35, stir magnetically for 48 hours at an oil bath temperature of 150° C., and then centrifuge and wash it to obtain powder B.

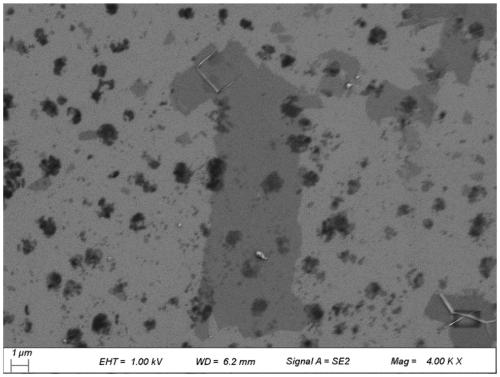

[0033] Step 3: Add B powder to 100ml deionized water, centrifuge at 6000rpm for 40min to remove small flakes and impurities, then centrifuge at 2000rpm for 60min, absorb the upper liquid to obtain a stable two-dimensional vermiculite nanosheet colloidal solution with a concentration of 8.0g / L.

[0034] Step 4: Take the vermiculite nanosheet solution obtained in step 3, and use a vacuum filtration device to st...

Embodiment 2

[0044] The steps of this example are the same as those of Example 1, except that the mass ratio of thermally expanded vermiculite, water and LiCl in step 1 is 1:40:5. In this embodiment, single-layer vermiculite nanosheets with substantially the same size as in Example 1 can be prepared, and the colloidal solution of nanosheets is 6.7 g / L. Through the test of the separation performance of the vermiculite film, it is found that the selectivity of the vermiculite film prepared in this example to molecules and ions is basically consistent with that of Example 1.

Embodiment 3

[0046]The steps of this example are the same as in Example 1, the difference is that the stirring time of step 1 is 18h, and this example can prepare a single-layer vermiculite nanosheet that is basically the same as that of Example 1, and the size of the vermiculite nanosheet is not affected by the stirring reaction time. However, the nanosheet colloidal solution was slightly lower at 6.5g / L. Through the test of the separation performance of the vermiculite film, it is found that the selectivity of the vermiculite film prepared in this example to molecules and ions is basically consistent with that of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com