Boiler environment-friendly purification device for power plant

A purification device and power plant technology, applied in the direction of electrical program control, use of liquid separation agent, chemical instruments and methods, etc., can solve the problems of poor trapping effect of small particle size particles, inability to adjust desulfurization liquid, waste of desulfurization liquid, etc. Achieve the effect of avoiding waste, improving purification effect and ensuring uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

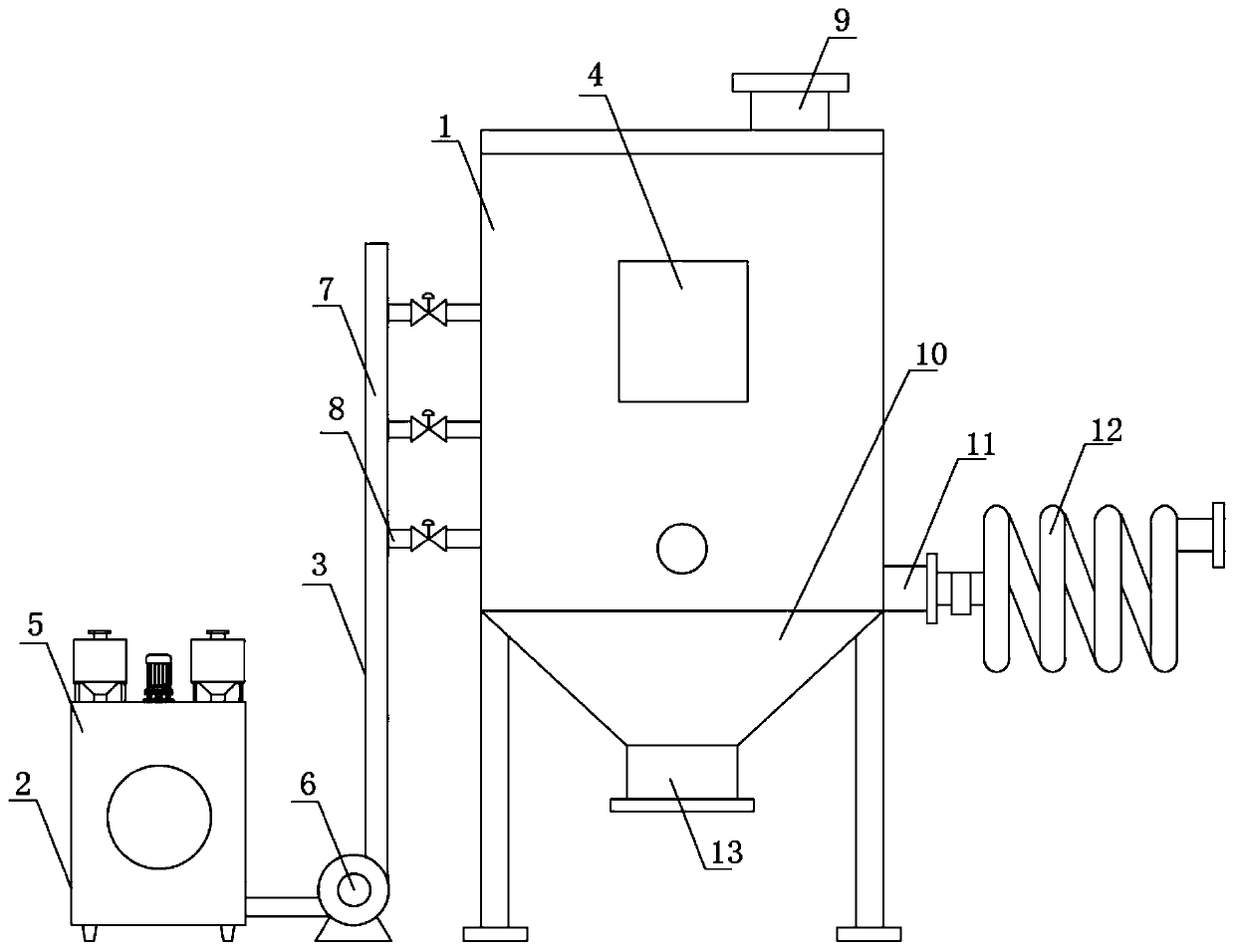

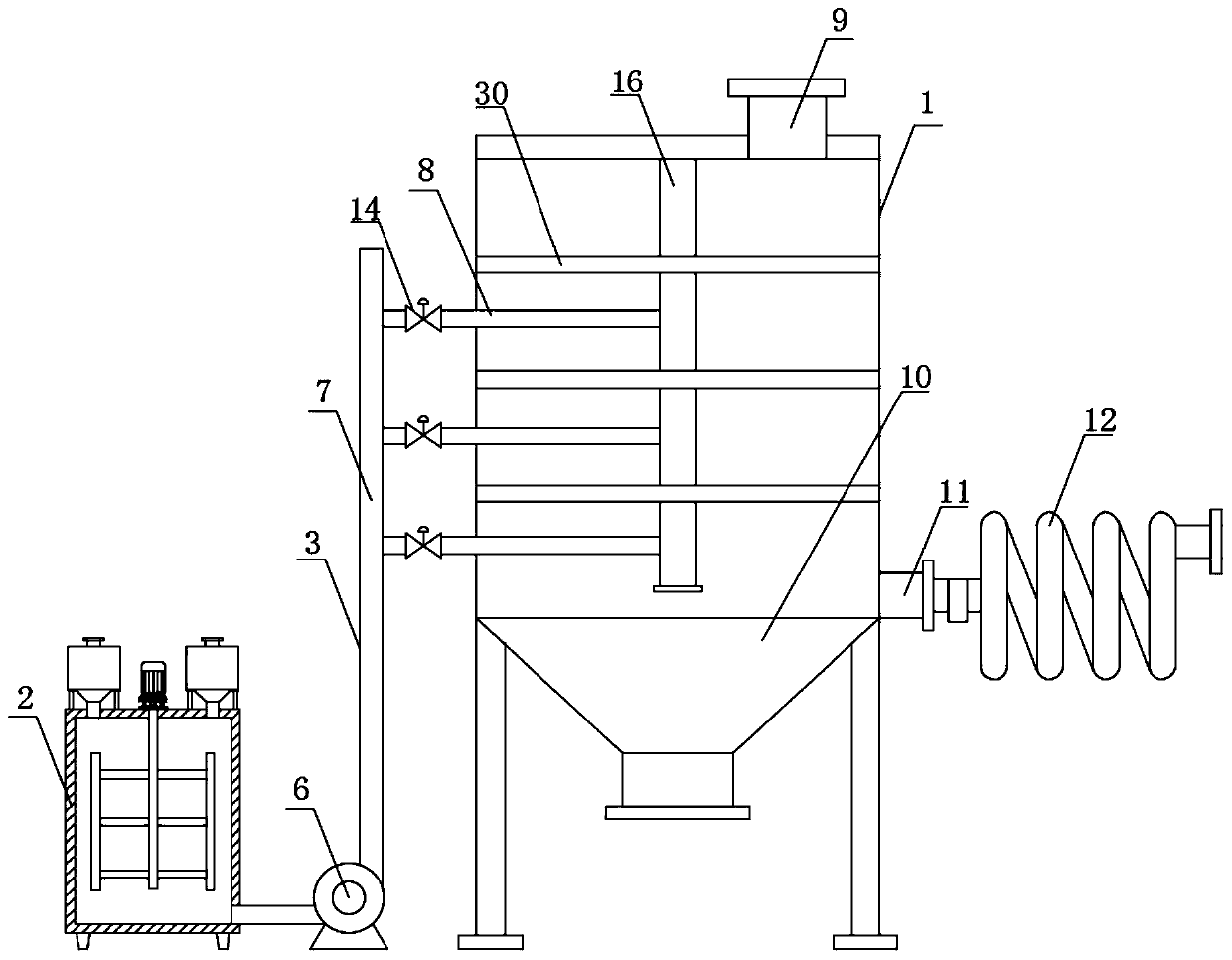

[0032] see Figure 1-7, the present invention provides a technical solution: an environmental protection purification device for a boiler in a power plant, comprising a cylinder body 1, a feeding mechanism 2, a water supply assembly 3 and a PLC controller 4, between the cylinder body 1 and the feeding mechanism 2 The water supply assembly 3 communicates with each other. The inside of the cylinder 1 is fixed with a spray main pipe 16 close to the axis for the desulfurization liquid to flow evenly into the spray assembly 30. One end of the cylinder 1 is fixedly connected with a flue gas inlet 11. , to facilitate the flue gas to enter the cylinder body 1 smoothly, one end of the flue gas inlet 11 is fixedly connected with a detection tube 12, and the inner wall surface of the detection tube 12 is fixedly installed with a sulfur dioxide sensor 25, and the dust-removed flue gas can be connected to the detection tube 12. The flue gas will pass through the detection tube 12 and then ...

Embodiment 2

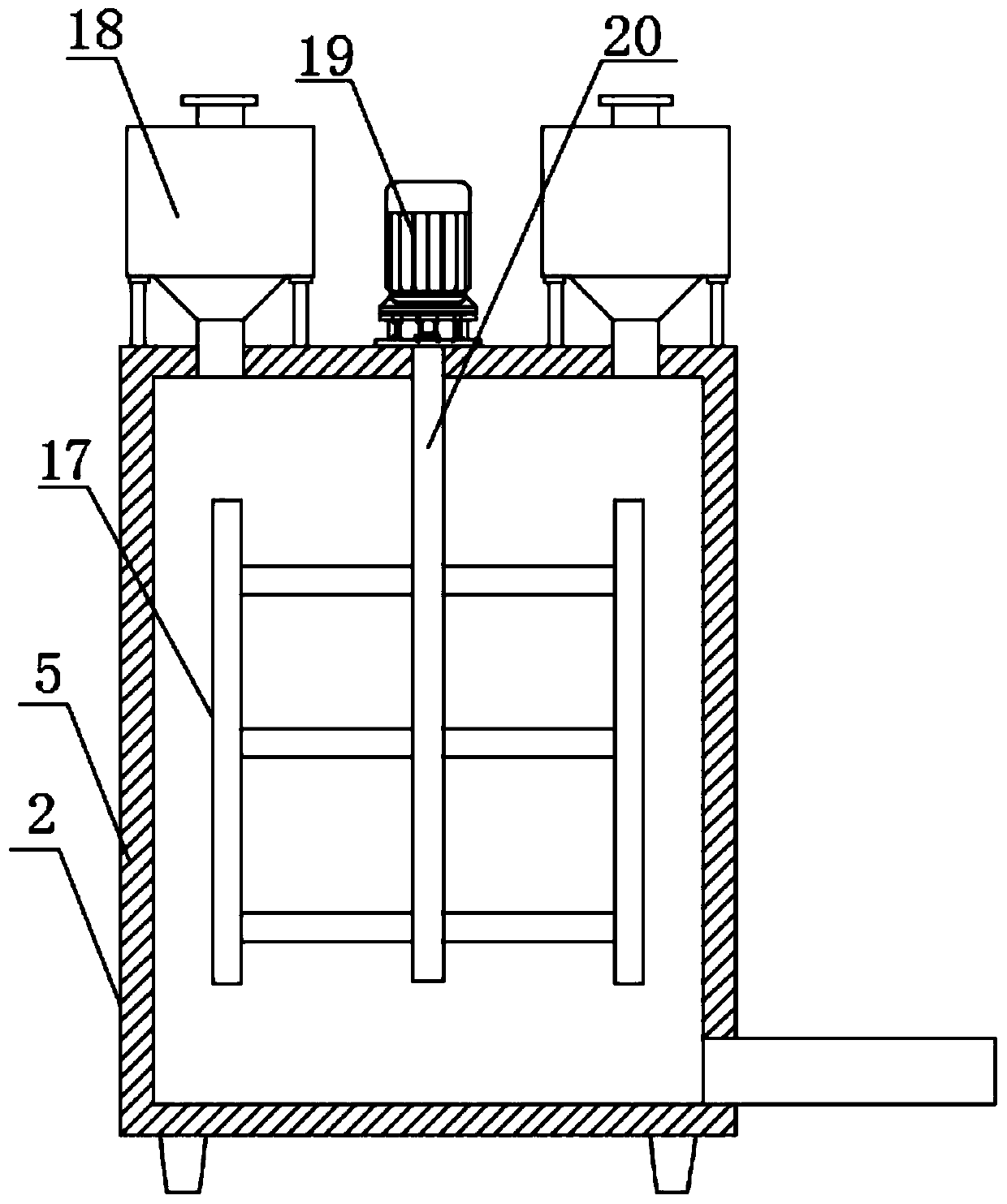

[0040] see Figure 1-7 , the present invention provides a technical solution: an environmental protection purification device for a boiler in a power plant, comprising a cylinder body 1, a feeding mechanism 2, a water supply assembly 3 and a PLC controller 4, between the cylinder body 1 and the feeding mechanism 2 The water supply assembly 3 communicates with each other. A spray main pipe 16 is fixedly installed inside the cylinder body 1 close to the axis. One end of the cylinder body 1 is fixedly connected with a smoke inlet 11. Pipe 12, the surface of the inner wall of the detection pipe 12 is fixedly equipped with a sulfur dioxide sensor 25, the feeding mechanism 2 includes a mixing tank 5, and the two sides of the top of the mixing tank 5 are fixedly installed with a material storage cylinder 18 through legs 21, so A weighing sensor 22 is fixedly installed between the material storage cylinder 18 and the support feet 21, and the bottom end of the storage cylinder 18 is fi...

Embodiment 3

[0042] see Figure 1-2 , the present invention provides a technical solution: a boiler environmental protection purification device for a power plant, the outer wall surface of the spray main pipe 16 is fixedly connected with a spray assembly 30, and there are three sets of spray assemblies 30, since the spray assembly 30 is set There are three groups, which can realize a three-layer purification process, thereby ensuring the purification effect of the flue gas. The spray assembly 30 includes a No. 1 spray branch pipe 15, and the No. 1 spray branch pipe 15 is fixedly connected to the inner wall surface of the cylinder body 1. Used to support and fix the spray assembly 30, the No. 1 spray branch pipe 15 and the spray main pipe 16 are fixedly connected with the No. 2 spray branch pipe 28, and the No. 2 spray branch pipe 28 is provided with six groups to improve desulfurization. The spraying area of the liquid, the middle end of the No. 2 spray branch pipe 28 is fixedly connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com