A stable structure of the main coolant pipeline of ap1000 nuclear power plant and its vibration adjustment process

A main coolant and pipeline technology, applied in the field of stable structure and vibration adjustment technology, can solve the problems of easy displacement of pipelines and unstable pipelines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

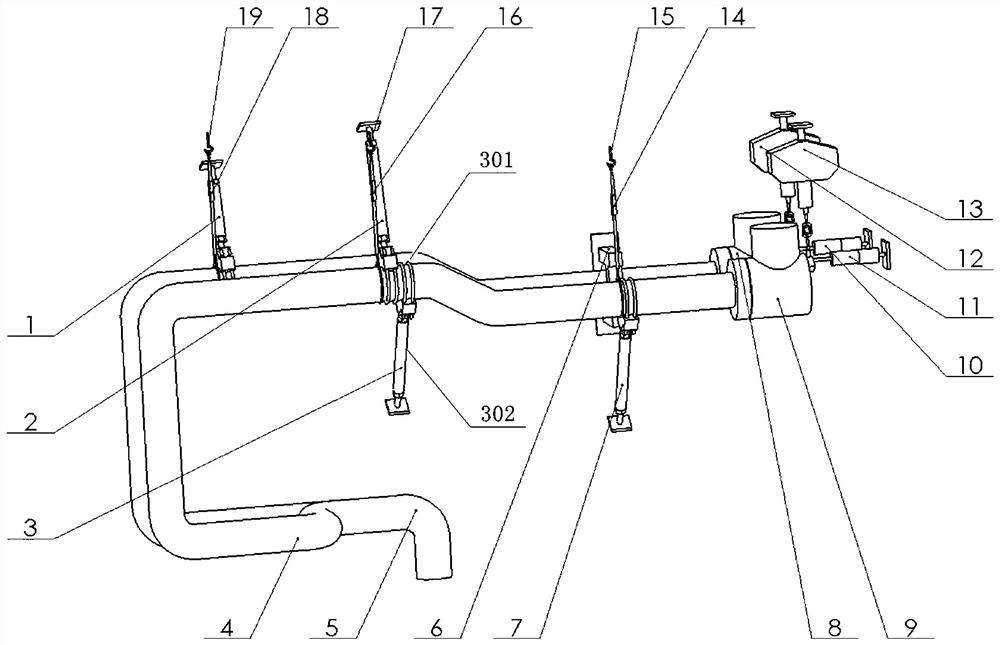

[0077] A stable structure for the main coolant pipeline of a nuclear power plant, including a rigid support, a rigid door frame, a constant force hanger and a damper, which are respectively arranged on two rows of outgoing pipelines. The rigid support includes an upper rigid support A1, an upper rigid support B2, lower rigid support A3 and lower rigid support B7;

[0078] The upper rigid support A1 and the rigid door frame 6 are installed on one of the outgoing pipelines, and the upper rigid support B, lower rigid support A, and lower rigid support B are installed on the other column of outgoing pipelines; the ends of the two outgoing pipelines 4 are respectively connected to constant force cranes A12 And constant force crane B13, damper A10 and damper B11, as attached figure 2 As shown, the constant force crane is installed vertically, and the damper is installed horizontally;

[0079] Each of the rigid brackets includes a holding card 301 connected to the pipeline and a sup...

Embodiment 2

[0115] Between steps S-31 and S-32, add a step: bend the two fins of the stop washer so that they are as vertical as possible to the holding card and fit together. You can try to bend one before tightening the nut torque. fins.

[0116] Between steps S-33 and S-34, add a step: apply Loctite 2432 locking agent on the thread of the rigid bracket casing, and continue to tighten 1 / 8-1 / 4 after the lock nut is tightly attached to the casing During the circle, keep the bracket sleeve not to rotate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com