Engine silencer structure with damping structures

A technology of damping structure and muffler, which is applied in the direction of engine components, machines/engines, noise reduction devices, etc., can solve the problem of unsatisfactory noise reduction effect of the muffler, and achieve the effect of improving the noise reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

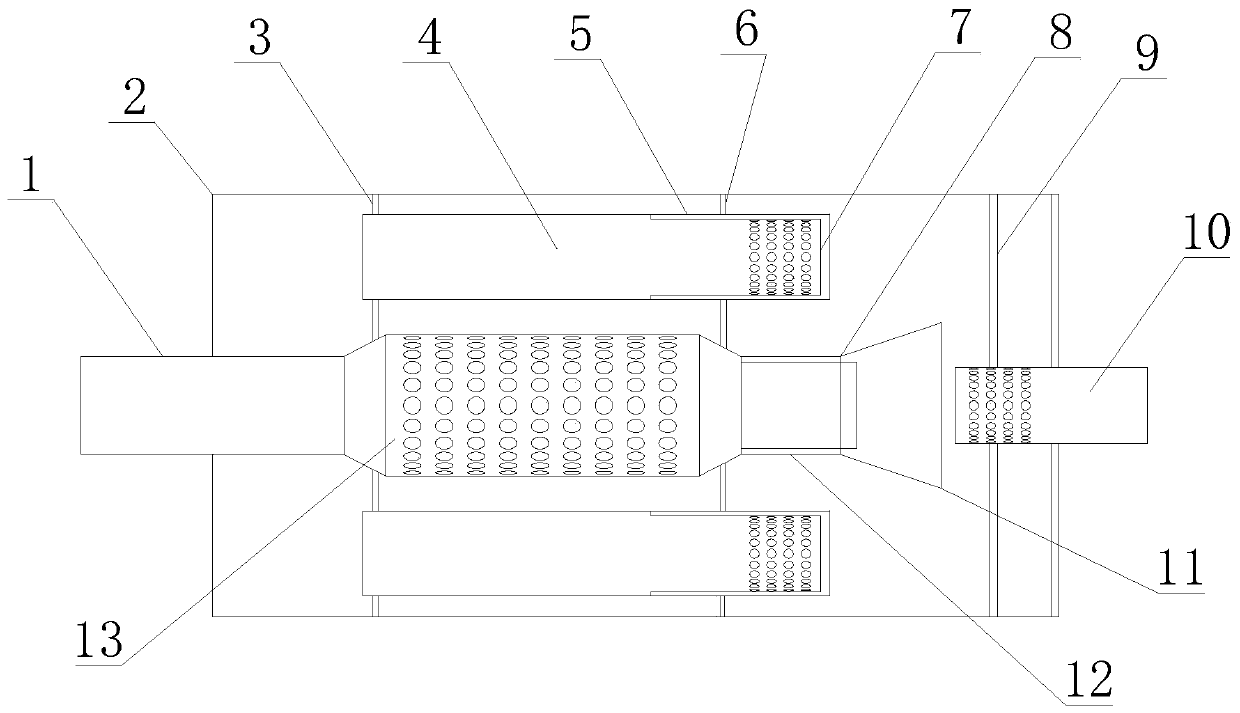

[0013] Embodiment 1 of the present invention: a muffler structure with a damping structure, including a smoke inlet pipe 1 and a sealed casing 2, one end of the smoke inlet pipe 1 is located in the casing 2, and the other end of the smoke inlet pipe 1 is located in the casing 2 outside; one end of the smoke inlet pipe 1 located in the housing 2 is connected with a first muffler pipe 13, and the first muffler pipe 13 is provided with a muffler hole; one end of the first muffler pipe 13 communicates with the smoke inlet pipe 1, and the first The other end of the muffler pipe 13 is provided with a first damping structure 8; the first damper structure 8 includes a first outer sleeve 11 and a first inner sleeve 12, and one end of the first outer sleeve 11 is fixed on the first muffler pipe 13 , the other end of the first outer sleeve 11 is sealed, the first inner sleeve 12 is sleeved in the first outer sleeve 11; the end of the first inner sleeve 12 close to the first muffler pipe 1...

Embodiment 2

[0015] Embodiment 2: A muffler structure with a damping structure, including a smoke inlet pipe 1 and a sealed casing 2, one end of the smoke inlet pipe 1 is located inside the casing 2, and the other end of the smoke inlet pipe 1 is located outside the casing 2; One end of the smoke inlet pipe 1 located in the housing 2 is connected to a first muffler pipe 13, and a muffler hole is provided on the first muffler pipe 13; one end of the first muffler pipe 13 communicates with the smoke inlet pipe 1, and the first muffler pipe 13 The other end of the first damping structure 8 is provided; the first damping structure 8 includes a first outer sleeve 11 and a first inner sleeve 12, and one end of the first outer sleeve 11 is fixed on the first muffler pipe 13, and the first The other end of the outer sleeve 11 is sealed, and the first inner sleeve 12 is sleeved in the first outer sleeve 11; the end of the first inner sleeve 12 close to the first muffler pipe 13 has an opening, and t...

Embodiment 3

[0018] Embodiment 3: A muffler structure with a damping structure, including a smoke inlet pipe 1 and a sealed casing 2, one end of the smoke inlet pipe 1 is located inside the casing 2, and the other end of the smoke inlet pipe 1 is located outside the casing 2; One end of the smoke inlet pipe 1 located in the housing 2 is connected to a first muffler pipe 13, and a muffler hole is provided on the first muffler pipe 13; one end of the first muffler pipe 13 communicates with the smoke inlet pipe 1, and the first muffler pipe 13 The other end of the first damping structure 8 is provided; the first damping structure 8 includes a first outer sleeve 11 and a first inner sleeve 12, and one end of the first outer sleeve 11 is fixed on the first muffler pipe 13, and the first The other end of the outer sleeve 11 is sealed, and the first inner sleeve 12 is sleeved in the first outer sleeve 11; the end of the first inner sleeve 12 close to the first muffler pipe 13 has an opening, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com