Sludge drying system based on biomass energy

A technology of sludge drying and biomass energy, applied in sludge treatment, water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, etc. problems, to achieve the optimization of the structure of the drying drum, the realization of the drying effect and the optimization of the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

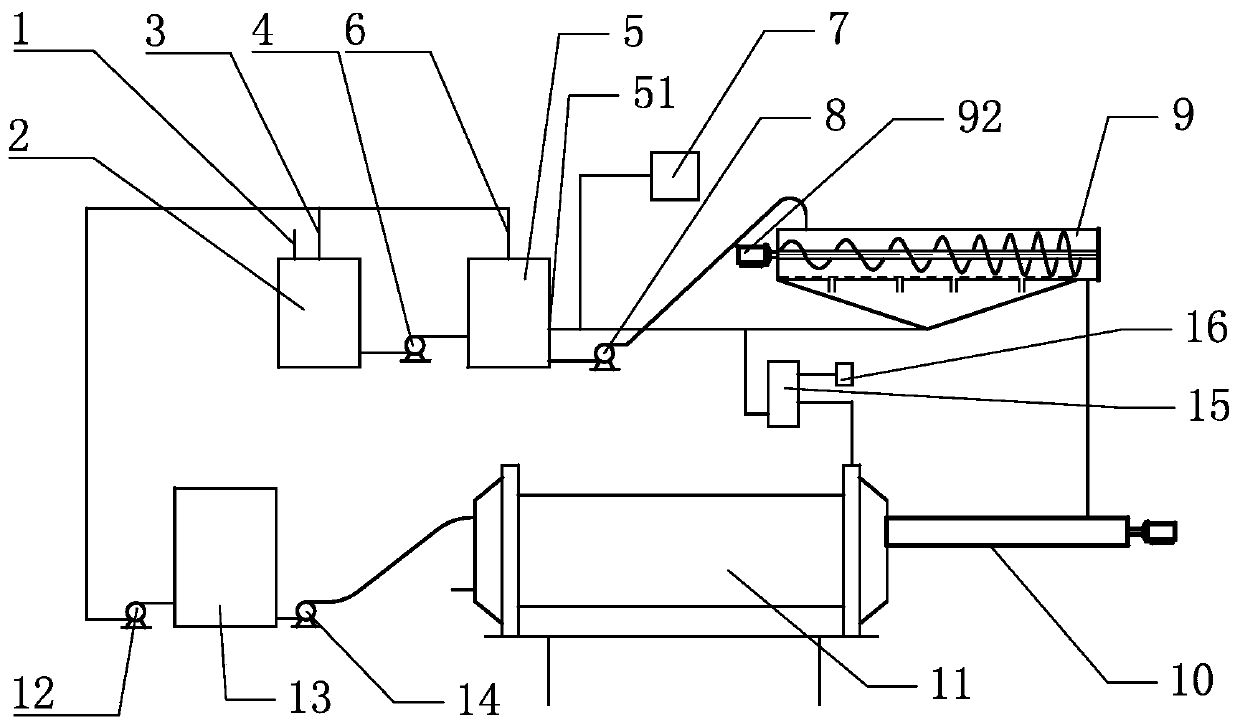

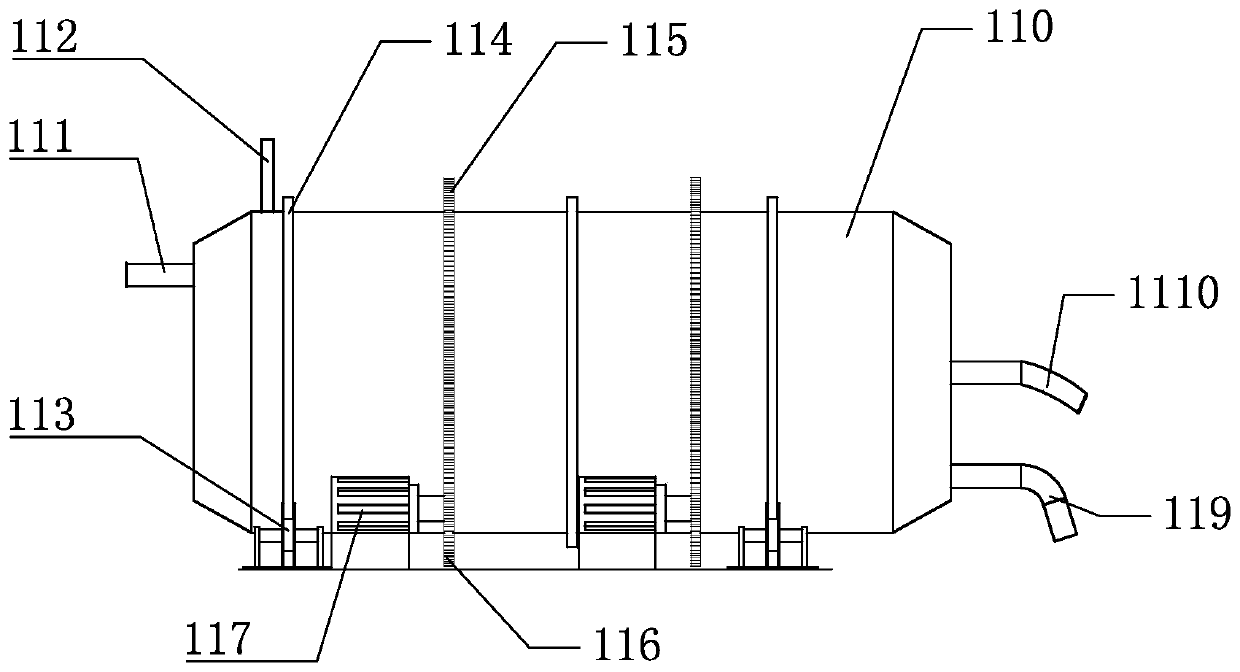

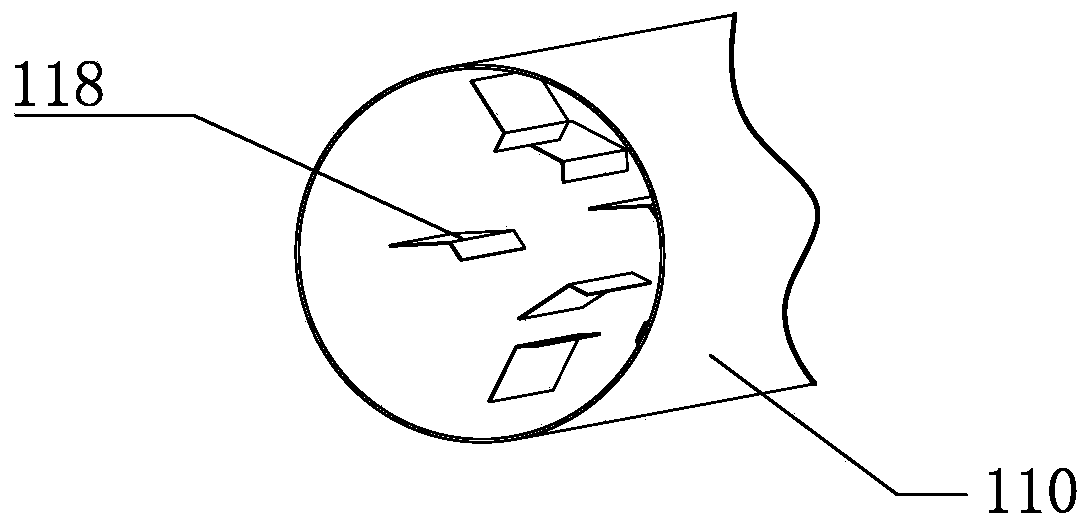

[0030] Such as Figure 1 to Figure 5 As shown, a sludge drying system based on biomass energy includes a sedimentation device, a dehydration device and a drying device arranged in sequence. The sedimentation device, dehydration device and drying device are connected in series by a conveying device, and the drying device is connected to a hot air device.

[0031] The settling device includes a stirring tank 2 and a sedimentation tank 5, the stirring tank 2 is provided with a raw sludge feed port 1 and a first air outlet 3, and the conveying device includes a first conveying pump 4, a second conveying pump 8, and the stirring tank 2 The first delivery pump 4 is connected to the sedimentation tank 5, and the sedimentation tank 5 is connected to the dehydration device through the second delivery pump 8. The top of the settling tank 5 is provided with a second air outlet 6, and the first air outlet 3 and the second air outlet 6 are respectively connected to the blower 12 through pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com