Vertical linear motor with iron core embedded in coil

A vertical linear, nested technology, applied in the field of motors, can solve problems affecting the application and development of linear motors, reduce motor vibration effects, poor stability and reliability, etc., to improve energy utilization and vibration force, and improve magnetic circuits , the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

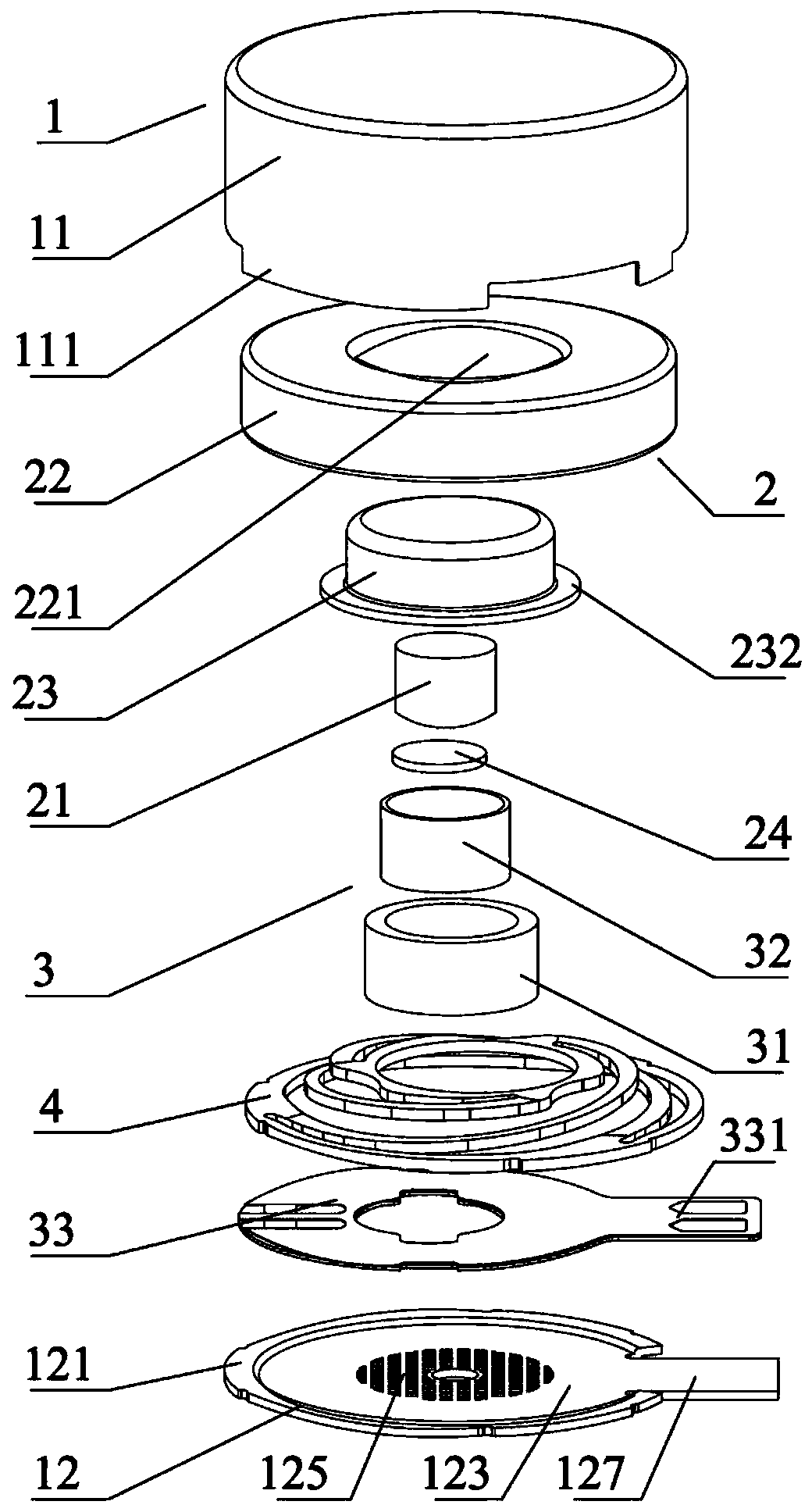

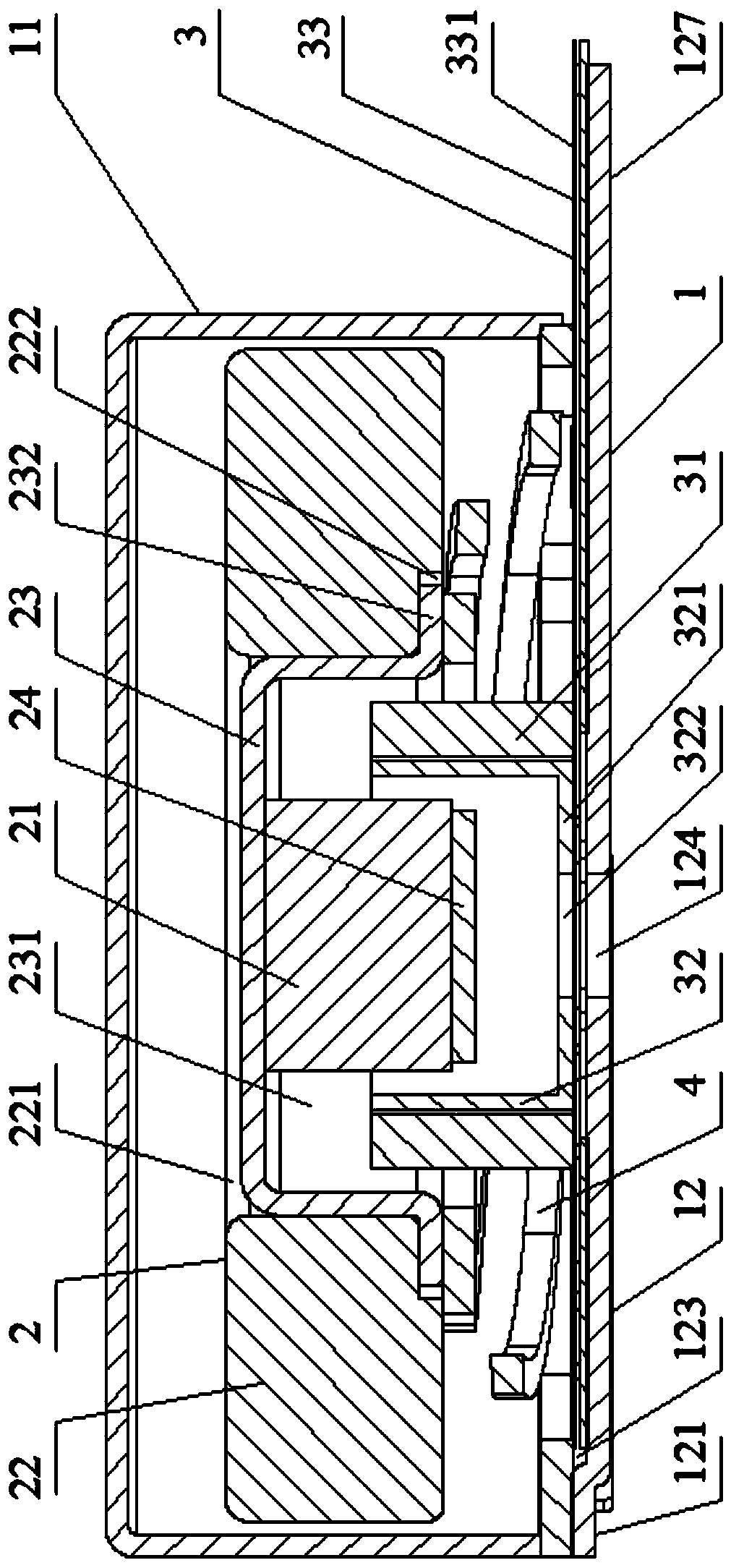

[0032] Such as Figure 1~6 As shown, a vertical linear motor with an iron core nested in a coil includes a casing 1. A mover assembly 2 and a stator assembly 3 corresponding to the mover assembly 2 are arranged in the casing 1. The mover assembly 2 is usually Located above the stator assembly 3 , the casing 1 includes an upper casing 11 and a lower casing 12 , the stator assembly 3 is arranged on the lower casing 12 , and the upper casing 11 and the lower casing 12 are usually welded together. The stator assembly 3 includes a coil 31. An iron core 32 is embedded in the coil 31. The coil 31 and the iron core 32 are usually fastened by glue. The coil 31 is connected to an external circuit through an FPC board 33. The coil 31 and the FPC board 33 are usually glued together The FPC board 33 and / or the coil 31 are usually glued and fixed on the lower casing 12, and the mover assembly 2 has a permanent magnet 21 corresponding to the coil 31, and the permanent magnet 21 is usually lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com