High-adaptive charging system and method for electric vehicle

A technology for electric vehicles and charging systems, applied in electric vehicles, battery circuit devices, battery/fuel cell control devices, etc., can solve problems such as inability to directly apply charging facilities, restrict the development of electric vehicles, and mismatch charging voltages, and achieve improved The effect of charging experience, shortening charging time, and stable output current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to understand the content of the present invention more clearly, it will be described in detail with reference to the drawings and embodiments.

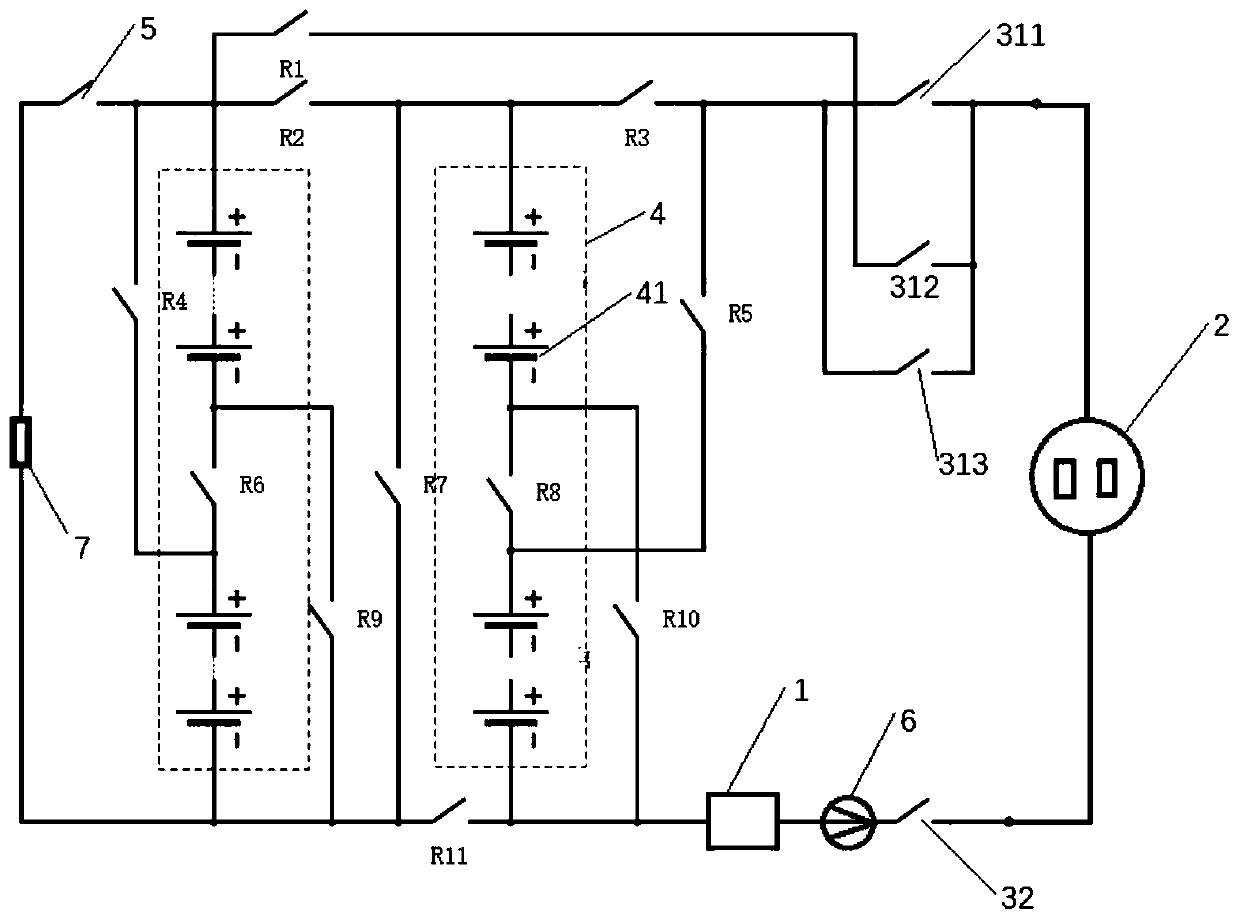

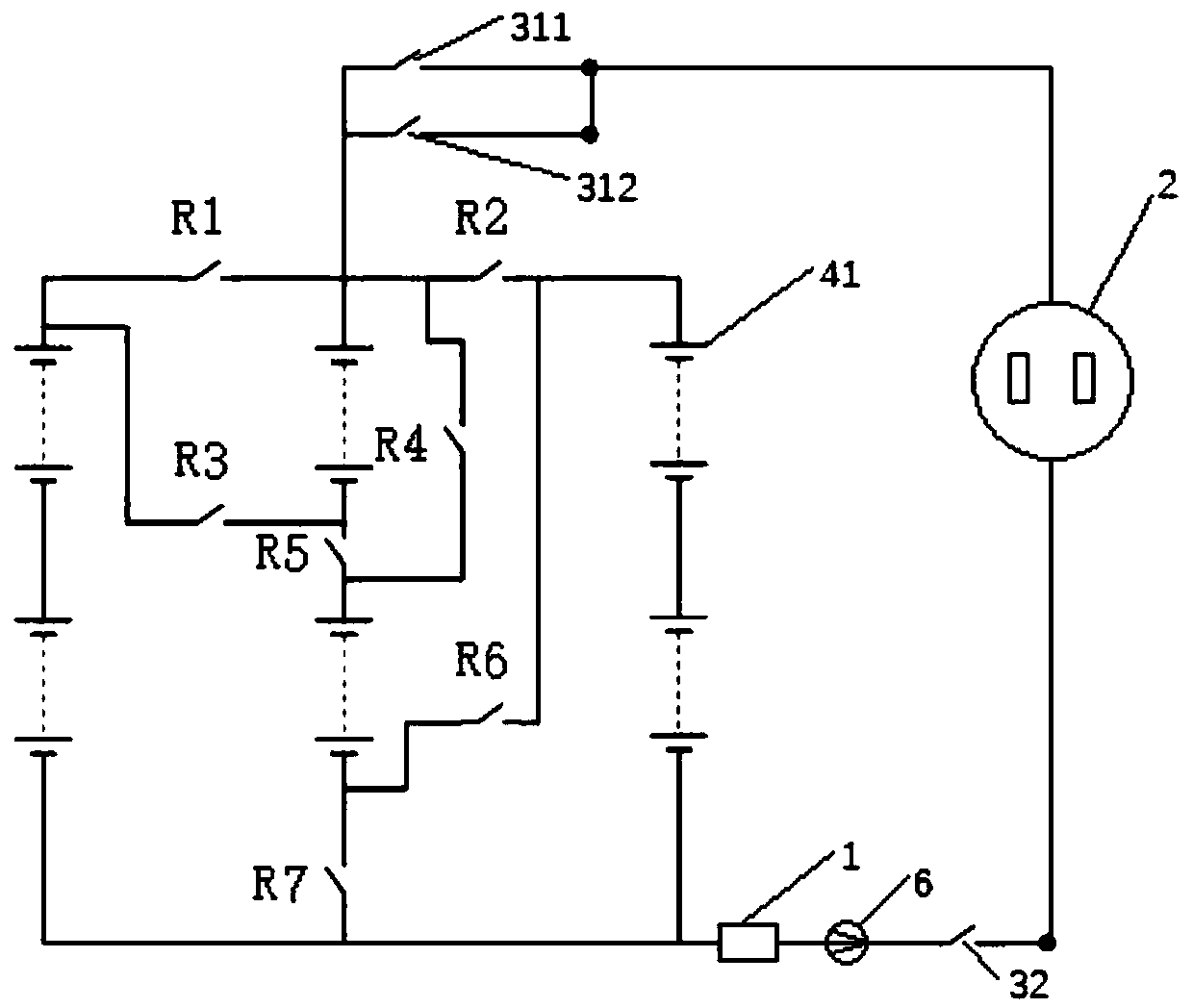

[0031]The first embodiment takes a power battery pack composed of 200 battery cells with a charging voltage upper limit of 4.2V as an example. In the normal discharge working state, the series-parallel structure of the battery cells in the power battery pack is two groups of 100 battery cells each forming a series structure and then connected in parallel to each other to form a power battery pack with a charging voltage upper limit of 420V (that is, the battery pack charging voltage upper limit It depends on the number of battery cells in the series structure multiplied by the upper limit of the charging voltage of a single battery cell), and it is assumed that the upper limit of the charging current of the power battery pack and the charging pile is 120A. Such as figure 1 As shown, the electric vehicle high adaptabi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com