Testing device for evaluating storage stability of thermal-pouring-type crack pouring glue for asphalt pavements and testing method

A technology for storage stability and stability testing, which is applied in the field of storage stability test devices for hot-filling joint-filling adhesives. It can solve the problems of inability to accurately evaluate the storage stability of hot-filling joint-filling adhesives for asphalt pavement, and achieve storage stability. performance, large overall size, and high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

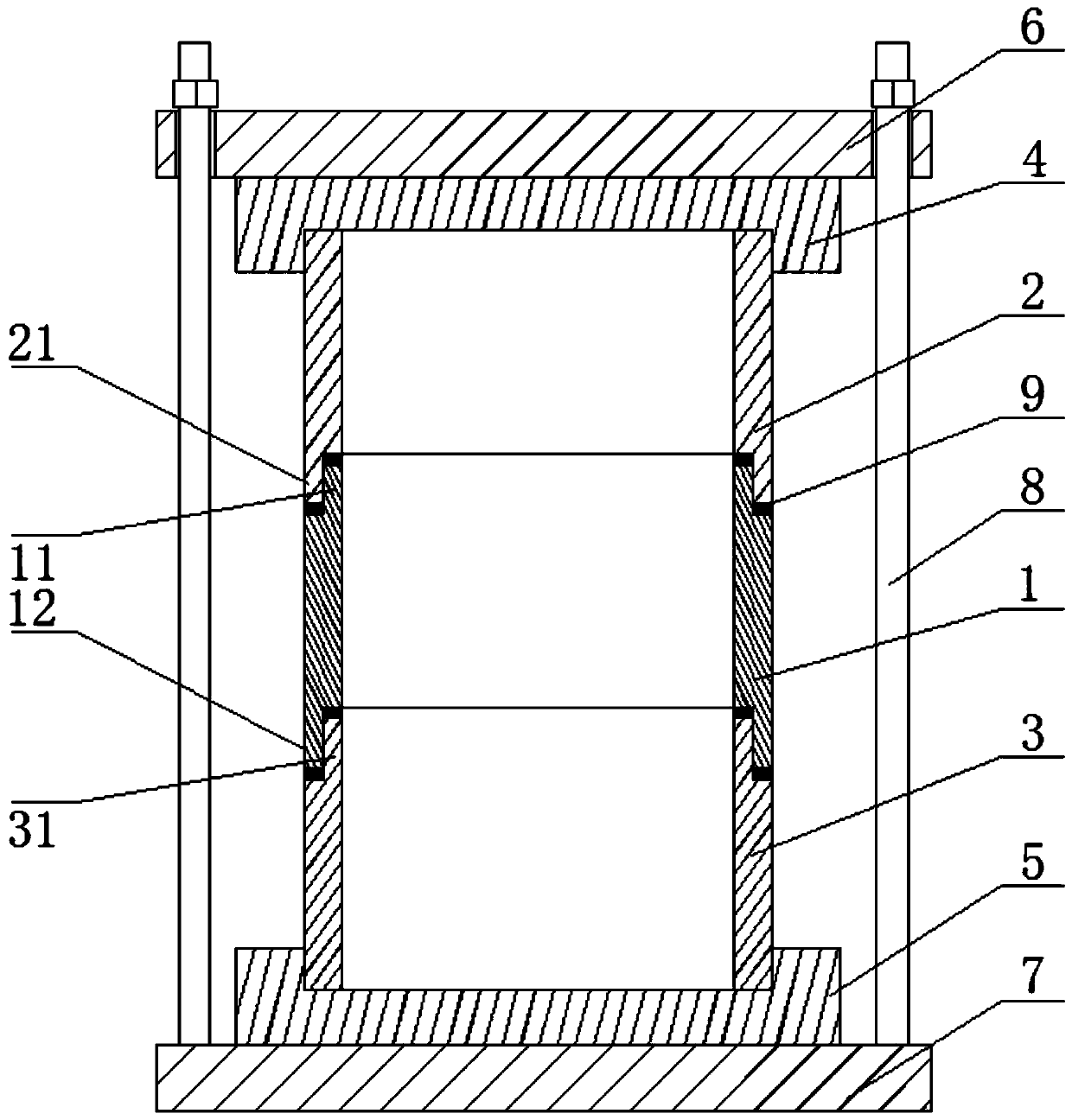

[0028] Specific Embodiment 1: In this embodiment, the test device for evaluating the storage stability test of asphalt pavement hot-filling joint grouting glue is composed of a multi-section combined cylinder, two end covers and two pressure plates; The two ends of the cylindrical barrel, the two end caps and the multi-section combined cylindrical barrel are arranged between the two pressure plates.

[0029] This embodiment has the following beneficial effects:

[0030] 1. The inner diameter of the test device of the present invention is much larger than that of the sample tube (2.5cm in diameter), which can more realistically simulate the storage and segregation phenomenon of the joint glue; two end caps are used to seal the two ends of the multi-section combined cylinder, and two As a fixing device, the pressure plate is used to compress the multi-section combined cylinder and the two end caps, and there are sealing gaskets between the cavities to ensure the airtightness dur...

specific Embodiment approach 2

[0033] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the two end caps are respectively the upper end cap (4) and the lower end cap (5); the upper end cap (4) and the lower end cap (5) respectively A circular groove is provided, the upper end of the multi-section combined cylinder is embedded in the circular groove of the upper end cover (4), and the lower end of the multi-section combined cylinder is embedded in the circular groove of the lower end cover (5).

specific Embodiment approach 3

[0034] Specific embodiment three: the difference between this embodiment and specific embodiment one is: the two pressing plates are respectively the upper pressing plate (6) and the lower pressing plate (7), and the upper pressing plate (6) is arranged on the top of the upper end cover (4) On the surface, the lower pressing plate (7) is arranged on the lower surface of the lower end cover (5); the upper pressing plate (6) and the lower pressing plate (7) are connected and tightened by several pull rods (8).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com