Evaluation method for shear resistance and pore throat compatibility of viscoelastic particles

An evaluation method, viscoelasticity technology, applied in particle and sedimentation analysis, using stable shear force to test material strength, flow characteristics, etc., can solve the problem of inability to accurately measure particle pore throat compatibility of viscoelastic particle dispersion system Microscopic evaluation and measurement of particle properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The preparation of the viscoelastic particle dispersion system includes the following processes: preparation of the dispersion medium and preparation of the viscoelastic particle dispersion system.

[0040] The dispersion medium is one of simulated formation water, field injection water and deionized water.

[0041] The preparation process of the viscoelastic particle dispersion system is as follows: take a container, add a certain amount of dispersion medium into it, stir the dispersion medium and add a certain amount of viscoelastic particles evenly and slowly to avoid agglomeration of the viscoelastic particles, and continue stirring for a period of time. The viscoelastic particles are fully swollen, and the viscoelastic particle dispersion system is obtained.

[0042]Step 102, using a capillary rheometer to perform a shear rheological test on the viscoelastic particle dispersion system;

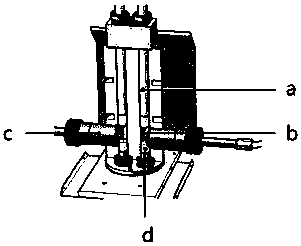

[0043] figure 1 It is a schematic diagram of a capillary rheometer, wherein ...

Embodiment 1

[0063] This example mainly evaluates the shear resistance performance of viscoelastic particles.

[0064] Experimental materials and equipment: organic viscoelastic particles PPG, composite viscoelastic particles F-PPG, produced by Shengli Oilfield Exploration and Development Research Institute, particle size 100-150 mesh; American IKA cantilever stirrer; British Malvern Rosand RH2000 capillary rheometer ; Anton Paar MCR 302 rheometer in Austria; Microtrac Bluewave laser particle size analyzer in the United States; Olympus optical microscope in Japan.

[0065] The test steps are as follows:

[0066] (1) Preparation of viscoelastic particle dispersion system

[0067] Accurately weigh 5g of the viscoelastic granular oil displacement agent sample (100-150 mesh), accurate to 0.0001g. Weigh 1L of simulated formation water into a 2000mL beaker, turn on the constant speed stirrer and slowly add the sample along the vortex wall at 400r / min for 30s, then stir for 2 hours at a stirrin...

Embodiment 2

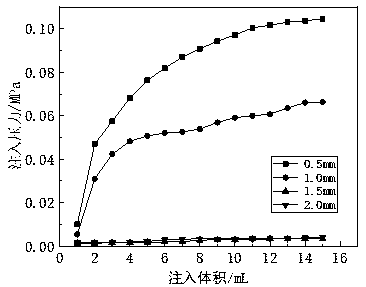

[0087] This example mainly evaluates the pore throat compatibility of viscoelastic particles.

[0088] Experimental materials and equipment: PPG viscoelastic particles, produced by Shengli Oilfield Exploration and Development Research Institute, particle size 100-150 mesh; American IKA cantilever stirrer; British Malvern Rosand RH2000 capillary rheometer; Austrian AntonPaar MCR 302 rheometer; American Microtrac Bluewave laser particle size analyzer; Japanese Olympus optical microscope.

[0089] The test steps are as follows:

[0090] (1) Preparation of viscoelastic particle dispersion system

[0091] Accurately weigh 5g of the viscoelastic granular oil displacement agent sample (100-150 mesh), accurate to 0.0001g. Weigh 1L of simulated formation water into a 2000mL beaker, turn on the constant speed stirrer and slowly add the sample along the vortex wall at 400r / min for 30s, then stir for 2 hours at a stirring rate of 500r / min to fully swell the viscoelastic particles , for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com