Energy storage type industrial hot air blower

A hot air blower, industrial technology, applied in heat storage heaters, fluid heaters, lighting and heating equipment, etc., can solve problems such as damage to instruments and meters, great influence on the accuracy of temperature control, and lagging sensor temperature detection , to achieve the effect of low cost, simple structure and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

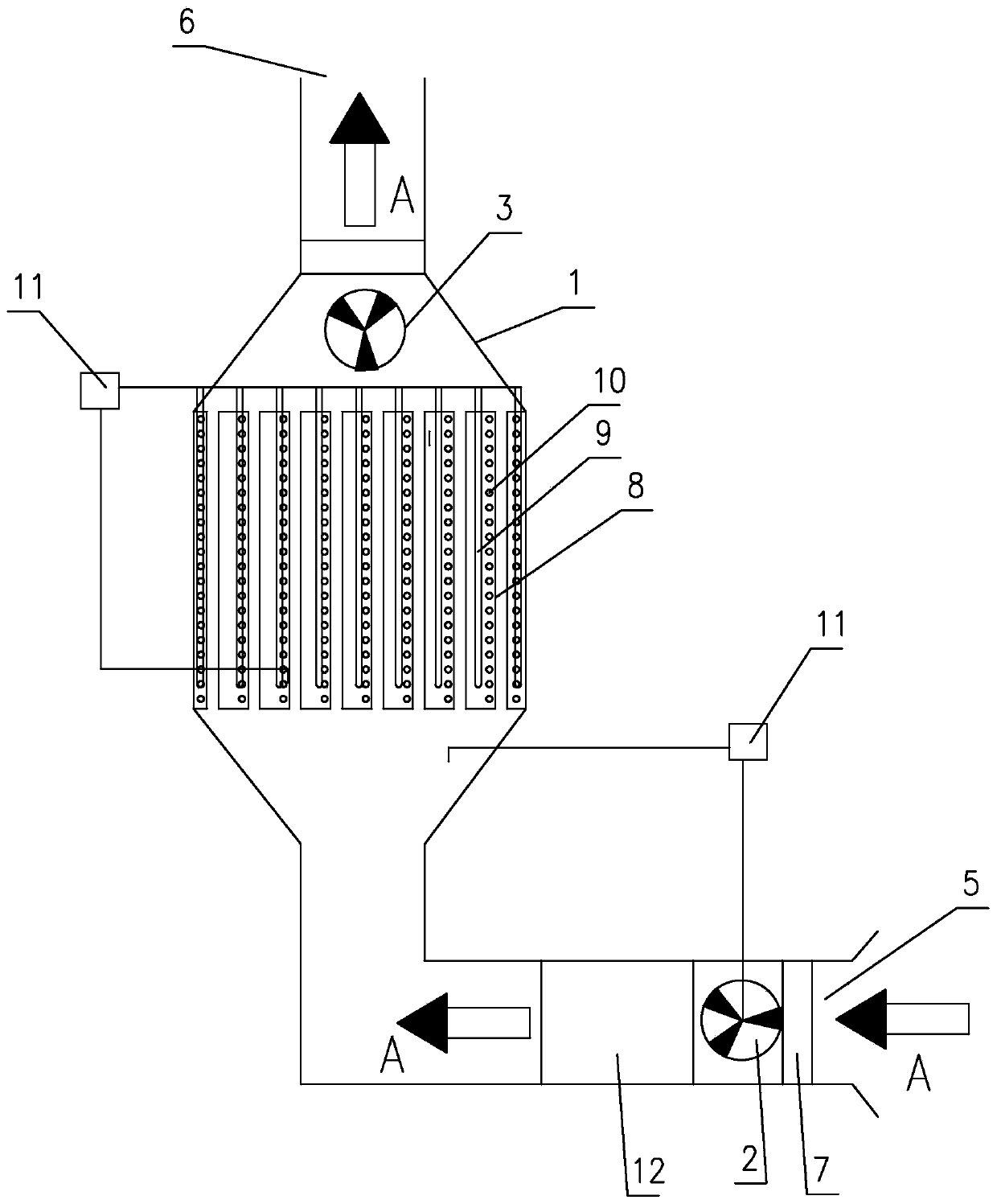

[0030] Such as figure 1 As shown, it is an energy storage type industrial hot air blower of the present invention, which includes a temperature control system, a casing 1, a first fan 2 arranged in the casing 1, a second fan 3, a heater 4, a condenser 7 and The heat storage device, the casing 1 has an air inlet 5 and an air outlet 6, the first fan 2 is arranged at the air inlet 5, and the second fan 3 is arranged in front of the heat storage device, that is, between the heat storage device and the air outlet 6. The heater adopts an electric heater, and the electric heater is located in front of the first fan 2, while the heat storage device is located in front of the electric heater, and the condenser 7 is used to condense and dry the cold air A, and it is located in the air inlet 5 And it is located behind the first fan 2 . The heat storage device includes a heat source, a casing and a heat storage material 10 filled in the casing. The maximum temperature of the phase transi...

Embodiment 2

[0036] Such as figure 2 As shown, the difference between this embodiment and Embodiment 1 is that the heater adopts the biomass oil furnace heater 12 .

[0037]The working process of this embodiment is: the cold air enters from the air inlet, passes through the condenser to condense and dry, and then is pumped by the fan to pass through the heater to heat the air. The heater is a biomass oil furnace heater, and the flame can be adjusted to at least three levels. . If the temperature exceeds the target temperature before entering the heat storage device, reduce the flame level. The heated hot air passes through the heat storage device and is reheated by the heat storage material. The electric heating tube of the heat storage device controls the temperature of the heat storage material to be in a quasi-constant temperature zone. The temperature of the hot air at the air outlet is determined and regulated by the temperature of the heat storage material and the speed of the fan...

Embodiment 3

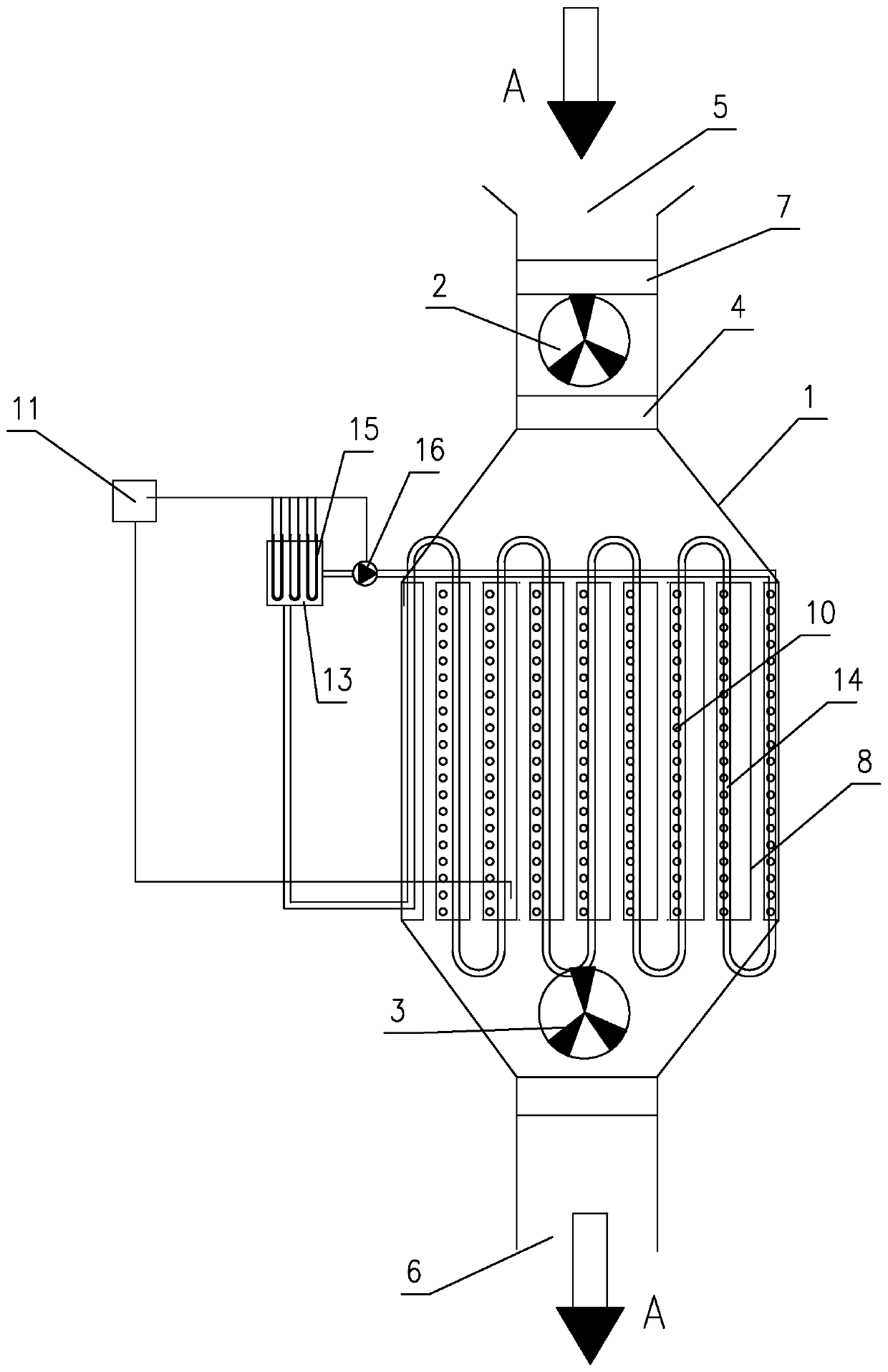

[0039] Such as image 3 As shown, the difference between this embodiment and Embodiment 1 is that the heat source is mainly composed of an oil tank 13 and a heating pipe 14. It is a serpentine tube, and the shell of the heat storage device is a plurality of tube bodies 8 arranged side by side and connected as a whole. The outer edge of the shell is connected with the inner wall of the casing. The heat storage material 10 is in contact. The heat conduction oil in the oil tank 13 is heated by the electric heating tube 15, and the controller 11 is connected with the electric heating tube 15 and the circulation pump 16 on the circulation circuit respectively, and is used to control the start and stop of the electric heating tube 15 and the circulation pump 16.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com