Totally upward air inlet combustor

A burner and ejector technology, which is applied to burners, gas fuel burners, combustion methods, etc., can solve the problems of inability to meet large-load ejection requirements, poor combustion stability, and small ejectors, and achieve large-scale ejection requirements. Power ejection requirements, good combustion stability, and the effect of reducing heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

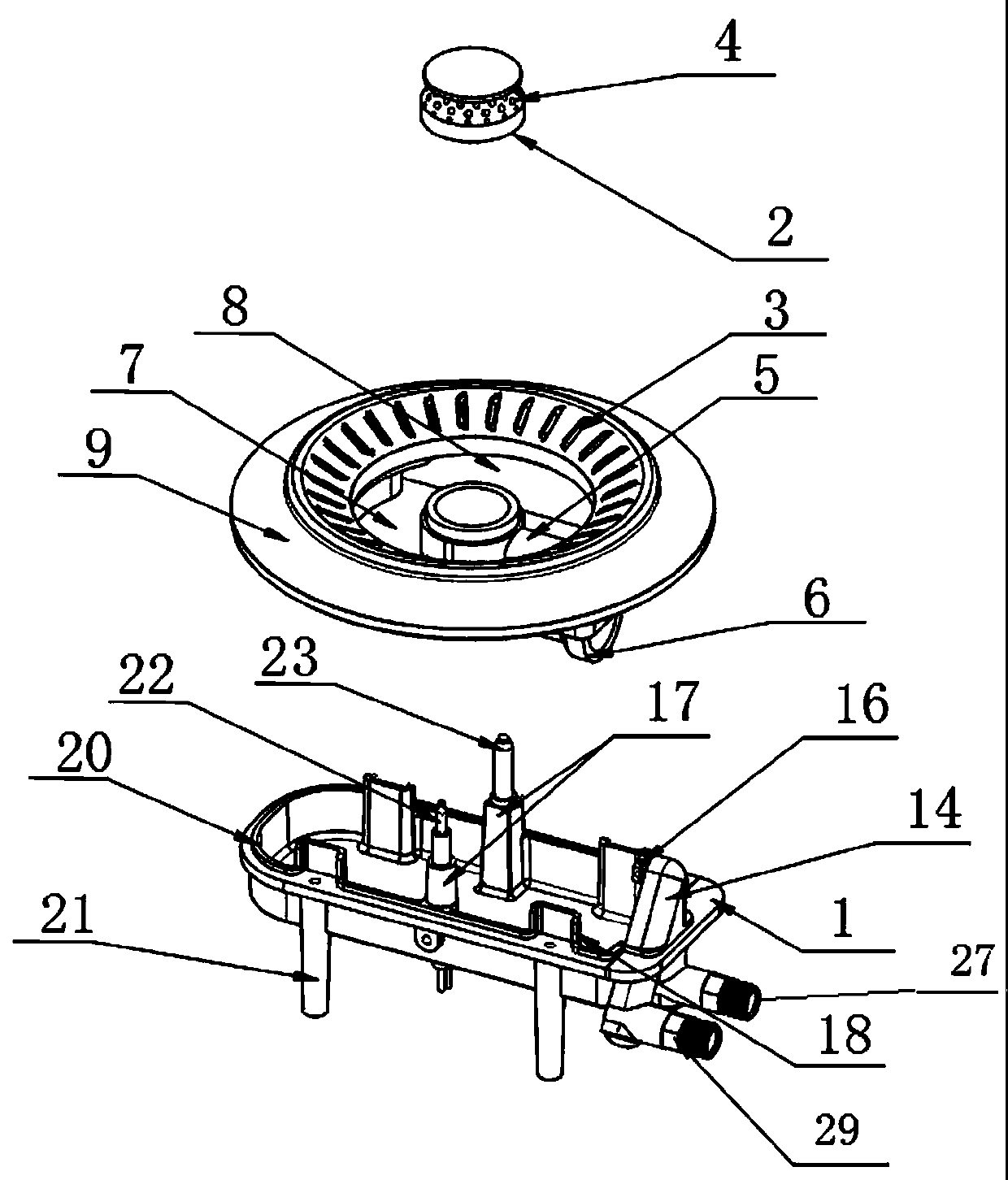

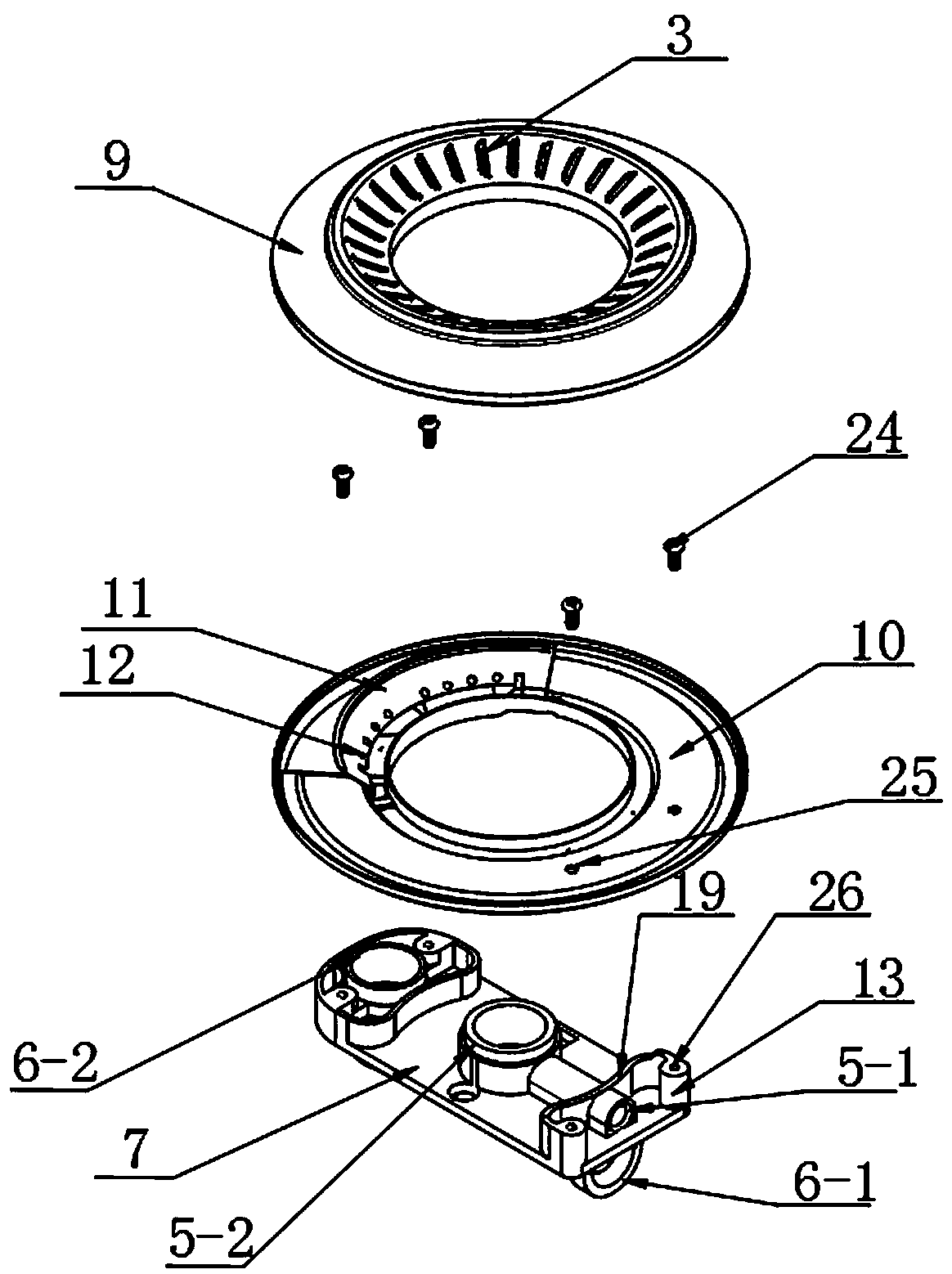

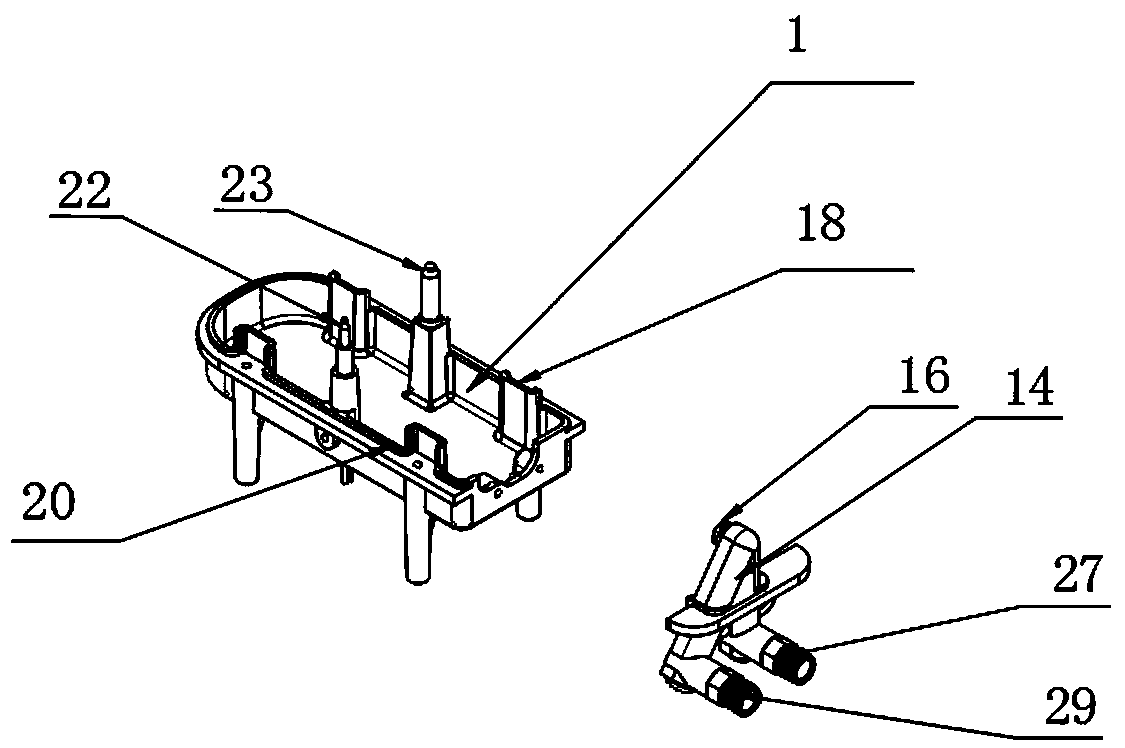

[0045] refer to Figure 1-8 , a completely upward air-intake burner, including a burner base 1, an injection module, a main fire distribution assembly and a central fire discharge cover 2, the main fire distribution assembly is provided with a main fire discharge hole 3, and a central fire discharge cover 2 is provided with a center fire outlet 4, and the main fire distribution assembly is provided with a main fire distribution cavity, and the injection module is arranged on the burner base 1, and the injection module includes a center fire ejector 5, a main fire The ejector 6 and the horizontal partition 7, the center fire ejector 5 is composed of the center fire inlet end 5-1 and the center fire gas outlet end 5-2 fixed in sequence, and the main fire ejector 6 is composed of the successively connected Main fire inlet end 6-1 and main fire o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com