STF-based anti-shock sliding shock isolator

A vibration isolator and sliding technology, which is applied to bridge parts, bridges, buildings, etc., can solve the problems of limited energy consumption, lack of anti-shock and vibration reduction, and difficult control of the horizontal displacement of the vibration-isolation support. Good anti-shock effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

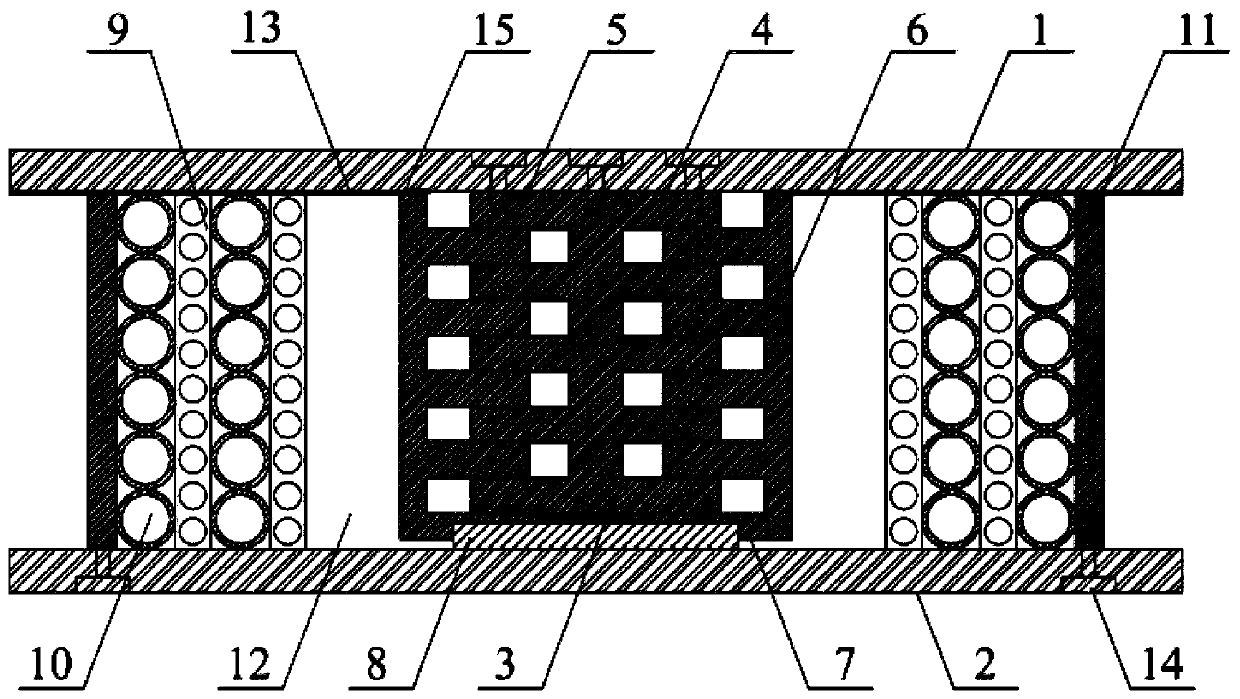

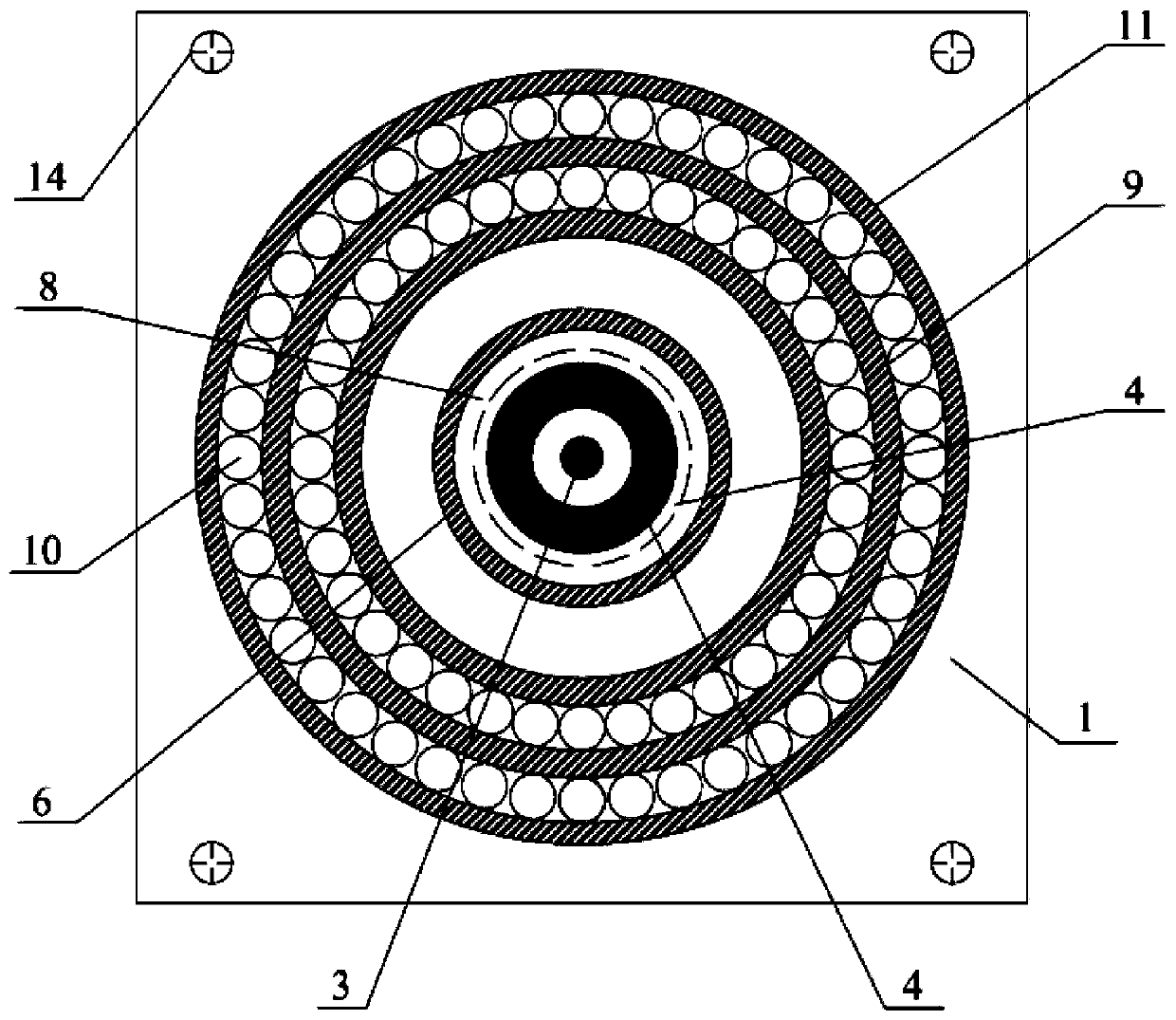

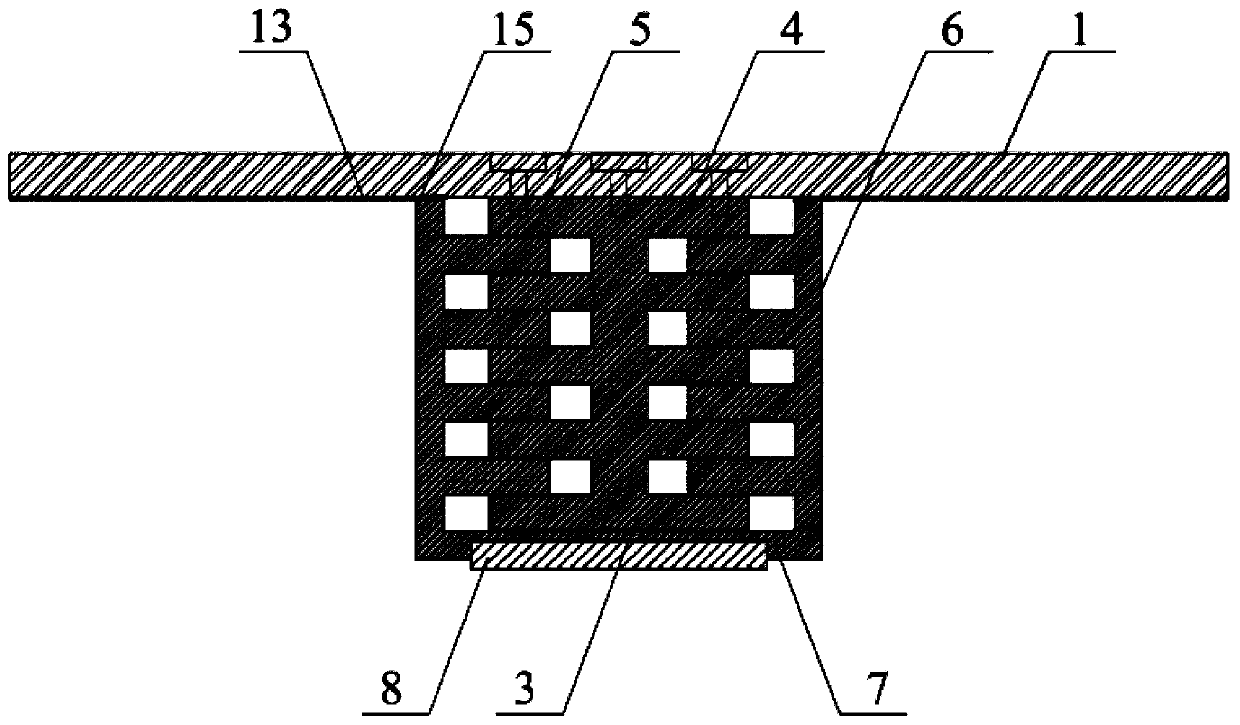

[0023] Example: see Figure 1-3 , the present invention provides a technical solution: a STF-based impact-slip shock isolator, which includes an upper cover plate 1, a lower bearing platform plate 2, a solid cylinder 3, a steel plate column 4, a sleeve 6, and a rubber plate 8 and sleeve two 11, the upper end of the sleeve two 11 is placed with the upper cover plate 1, the lower end of the sleeve two 11 is fixedly connected with the lower platform plate 2 through bolts 14, the cavity of the sleeve two 11 A solid cylinder 3 is also coaxially arranged inside the body, and the solid cylinder 3 is fixedly connected with the upper cover plate 1 through bolts 14. The outer coaxial sleeve of the solid cylinder 3 is provided with a sleeve one 6, and the solid cylinder 3 and the upper cover plate 1 are fixedly connected. Sleeve one 6 is respectively welded with steel plate column 4 along its vertical direction, and the bottom of described sleeve one 6 is welded with connection plate 7, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com