A high-efficiency energy-saving concrete slab

A concrete slab, high-efficiency and energy-saving technology, applied in roads, buildings, and pavement paved with prefabricated blocks, etc., can solve the problems of difficult cutting of concrete slabs, small diameter of cutting wheels, and labor and material resources, so as to prevent a large number of spread, Reduce the deformation range and enhance the effect of using the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

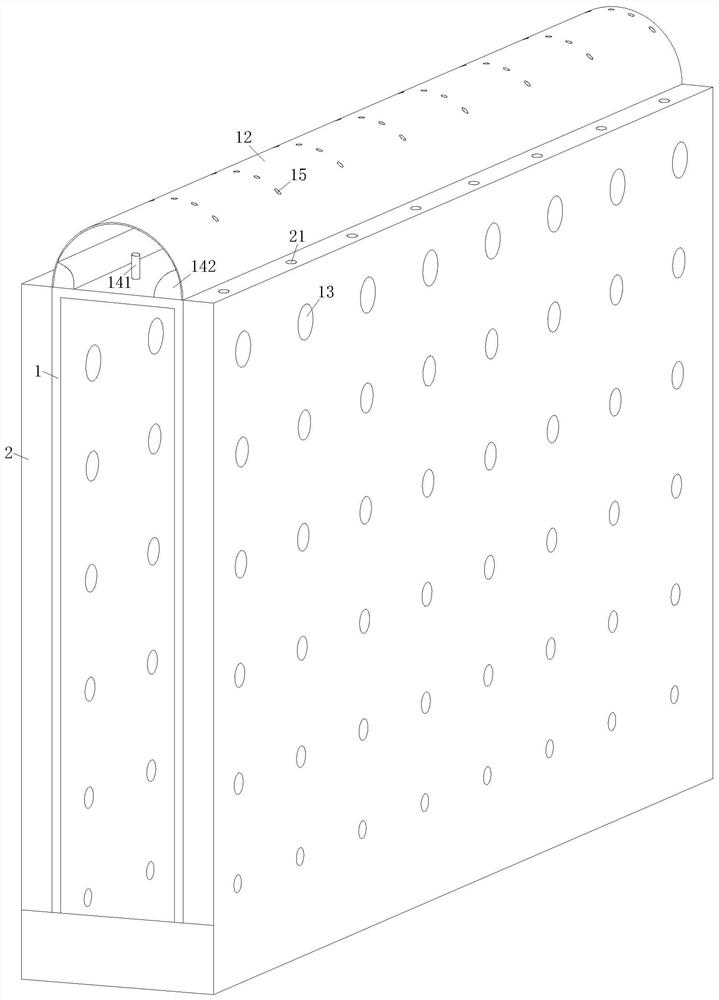

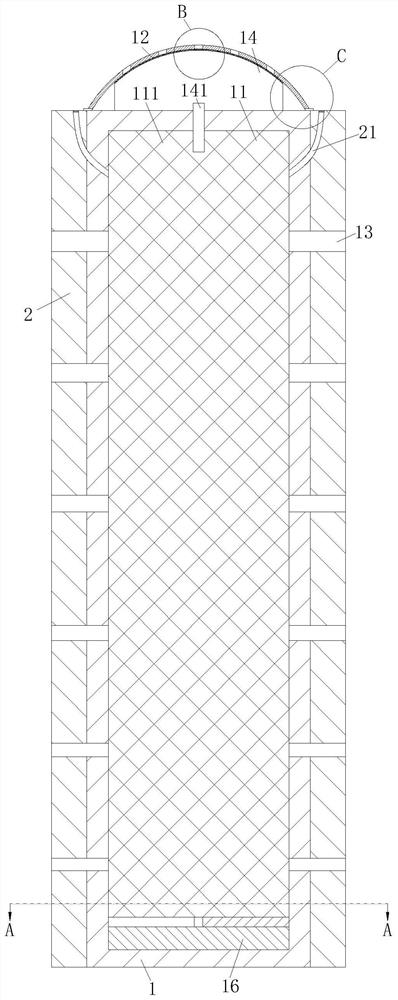

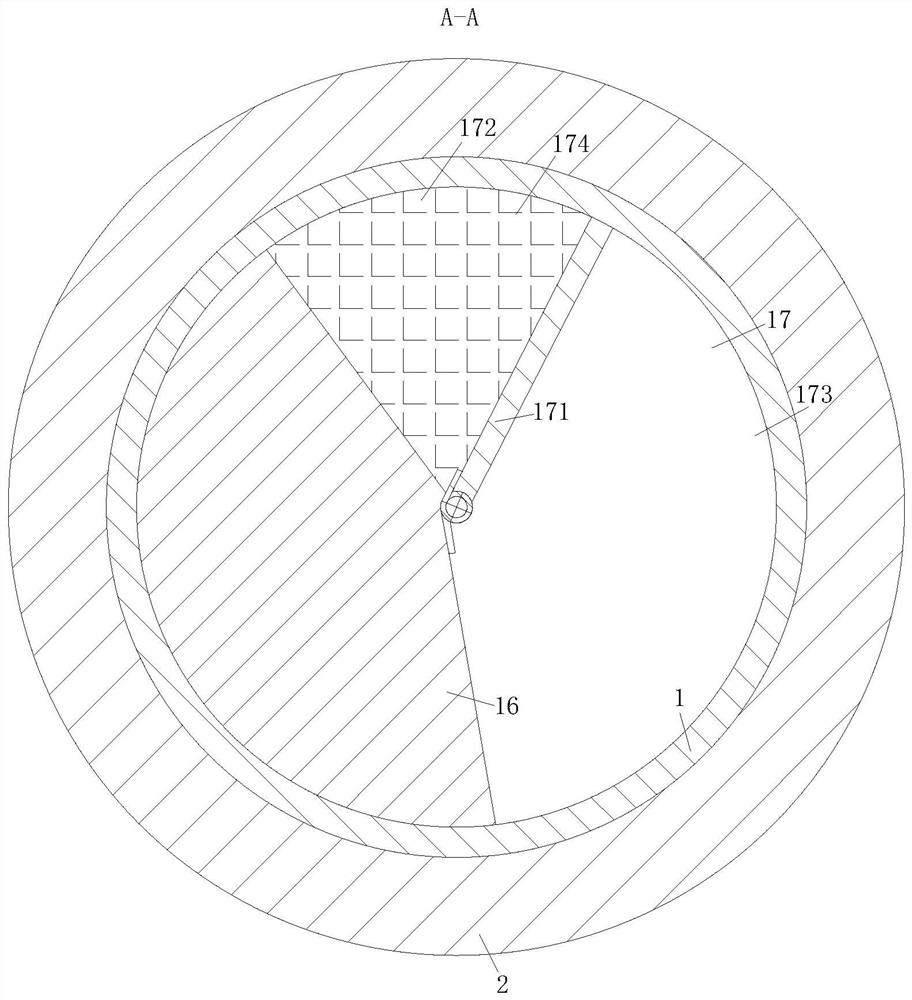

[0022]As an embodiment of the present invention, the top of the elastic plate 2 is provided with a water pipe 21 close to the metal cover 12; After the end passes through the elastic plate 2 and the partition 1, it contacts the pearl cotton 111 in the first cavity 11, and the top of the water pipe 21 is provided with a No. 1 filter 22; the side wall of the partition 1 has a No. 1 water hole 13 One end of the No. 1 water hole 13 is located on the inner side wall of the dividing plate 1 and contacts with the pearl cotton 111, and the other end of the No. 1 water hole 13 passes through the side wall of the dividing plate 1 and the elastic plate 2, and contacts with the outer side wall of the elastic plate 2; The collection of rainwater is realized through the cooperation of the flow pipe 21, the pearl cotton 111 and the No. 1 filter screen 22; during operation, when rainfall occurs in high-temperature areas, the rainwater dripping on the ground can flow into the No. 1 cavity throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com