Nickel/vanadium oxide hydrogen evolution electrode as well as preparation method and application thereof

A technology of hydrogen evolution electrode and vanadium oxide, which is applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, electrodes, etc., can solve the problems of very different hydrogen evolution performance, slow kinetic process, and large hydrogen evolution overpotential and other problems, to achieve superior performance, high-efficiency decomposition of water and hydrogen evolution, and low hydrogen evolution overpotential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

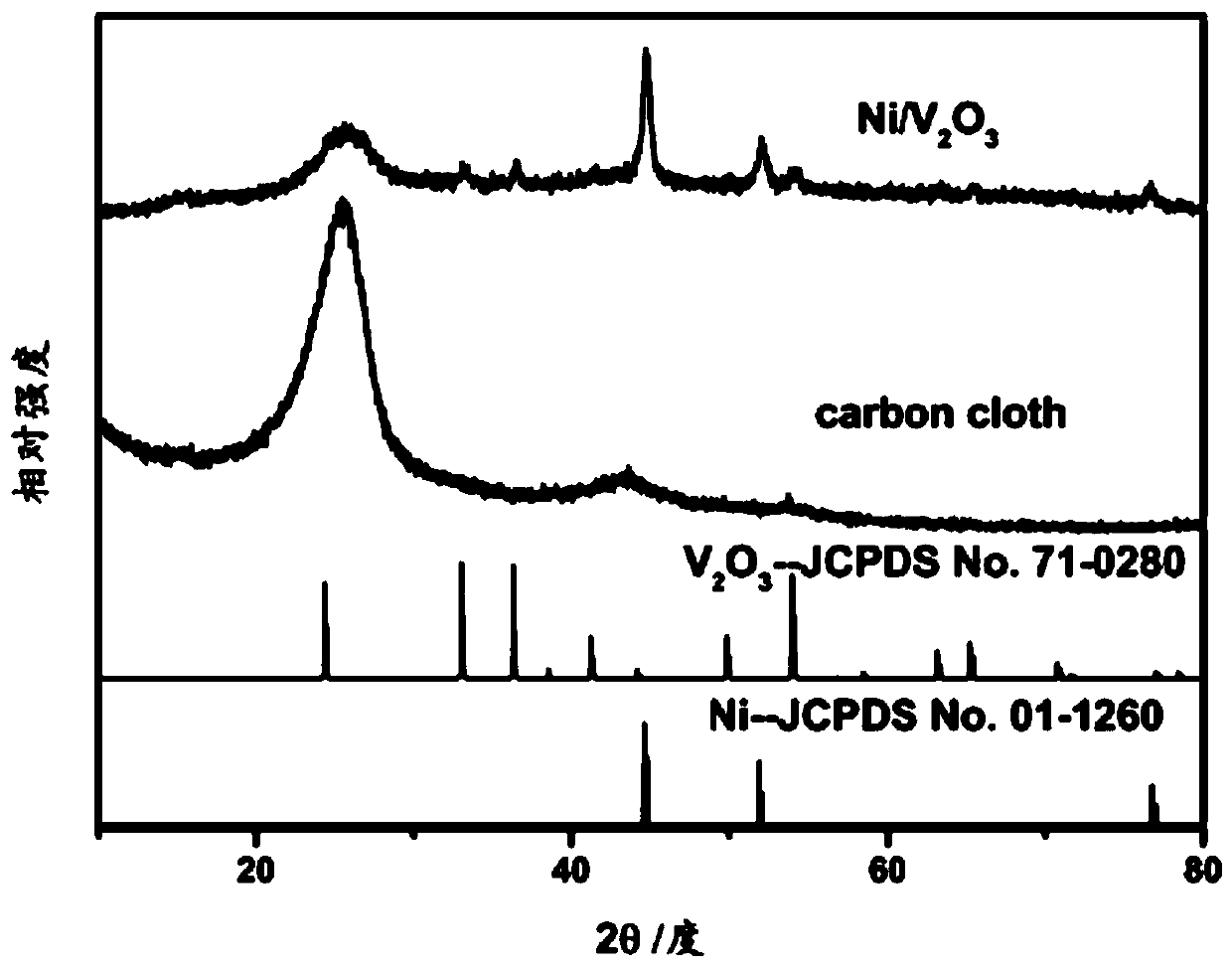

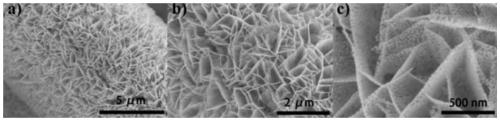

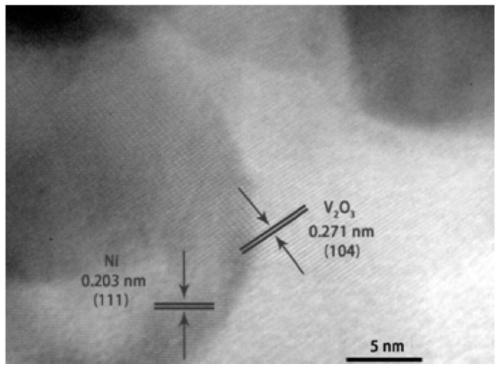

[0043] Ni / V involved in the present invention 2 o 3 The electrode preparation method steps are as follows:

[0044] Clean the carbon cloth base

[0045] In order to make the carbon cloth base more hydrophilic, soak the carbon cloth base in a mixed acid solution of sulfuric acid and nitric acid overnight, and then take it out and wash it with pure water and ethanol for 15 minutes respectively.

[0046] Preparation of NiV-LDH (Nickel Vanadium Layered Double Hydroxide) Precursor

[0047] Add 12mmol of urea and 6mmol of ammonium fluoride into 20ml of deionized water, and then add 0.8mmol of Ni(NO 3 ) 2 ·6H 2 O and 0.2 mmol of VCl 3 , after stirring evenly, pour the solution into a 20ml reaction kettle, and put a piece of cleaned carbon cloth in the reaction kettle, then seal the reaction kettle and put it in a 120 degree oven for 12 hours, and let it cool naturally after the reaction After reaching room temperature, the carbon cloth on which the active substance was grown w...

Embodiment 1

[0054] Preparation of NiV-LDH (Nickel Vanadium Layered Double Hydroxide) Precursor

[0055] Add 12mmol of urea and 6mmol of ammonium fluoride into 20ml of deionized water, and then add 0.8mmol of Ni(NO 3 ) 2 ·6H 2 O and 0.2 mmol of VCl 3 , after stirring evenly, pour the solution into a 20ml reaction kettle, and put a piece of cleaned carbon cloth in the reaction kettle, then seal the reaction kettle and put it in a 120 degree oven for 12 hours, and let it cool naturally after the reaction After reaching room temperature, the carbon cloth on which the active substance was grown was taken out, rinsed with ethanol and deionized water, and dried.

[0056] Preparation of Ni / V 2 o 3 electrode

[0057] Put the NiV-LDH precursor obtained above into a porcelain boat and seal it in a tube furnace, raise the temperature to 500 degrees at a rate of 8 degrees per minute in an argon-hydrogen atmosphere and keep it warm for 2 hours. After the reaction, the obtained The electrode is t...

Embodiment 2

[0061] Preparation of NiV-LDH (nickel-vanadium layered double hydroxide) precursors with different ratios of nickel and vanadium

[0062] Add 12mmol of urea and 6mmol of ammonium fluoride into 20ml of deionized water, and then add 0.6mmol of Ni(NO 3 ) 2 ·6H 2 O and 0.4 mmol of VCl 3 , after stirring evenly, pour the solution into a 20ml reaction kettle, and put a piece of cleaned carbon cloth in the reaction kettle, then seal the reaction kettle and put it in a 120 degree oven for 12 hours, and let it cool naturally after the reaction After reaching room temperature, the carbon cloth on which the active substance was grown was taken out, rinsed with ethanol and deionized water, and dried.

[0063] Preparation of Ni / V 2 o 3 electrode

[0064] Put the precursor obtained above into a porcelain boat and seal it in a tube furnace, raise the temperature to 500 degrees at a rate of 8 degrees per minute in an argon-hydrogen atmosphere and keep it warm for 2 hours. After the reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com