Film coating fixture

A jig and workpiece disk technology, applied in the field of coating jig, can solve the problems of poor optical performance of lenses, poor coating effect, complicated operation, etc., and achieve the effect of easy cleaning and maintenance, avoiding multiple clamping and avoiding pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

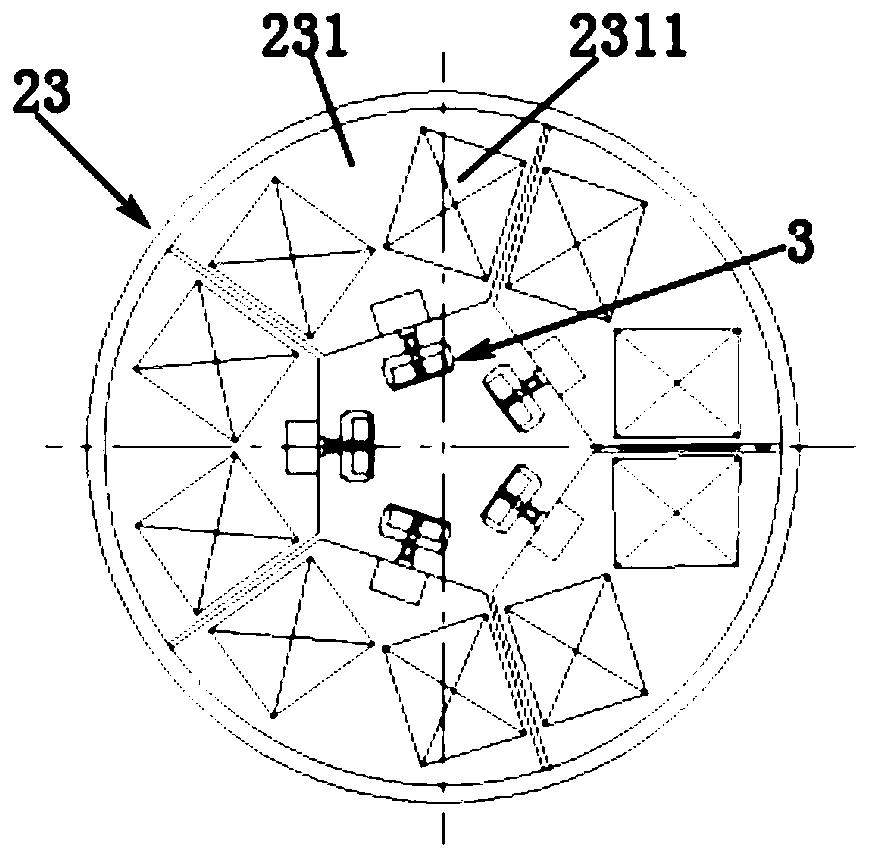

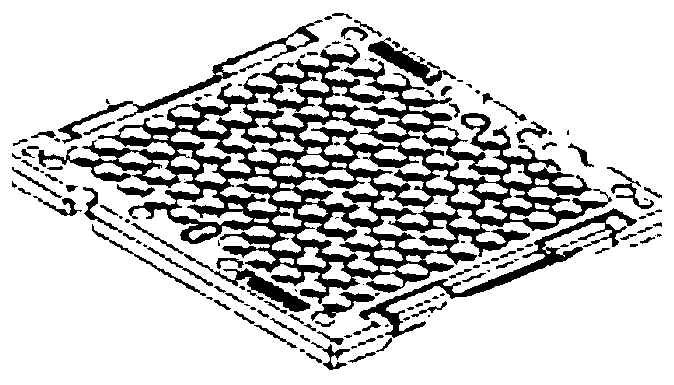

[0046] like Figure 4 As shown, according to the second embodiment of the present invention, the workpiece disk 23 is a disc-shaped structure, the workpiece disk 23 is integrally formed, and the workpiece sheet 23 is provided with a lens clamping area 2311 . In this embodiment, the lens clamping area 2311 is circular, and the rotating shaft 22 is connected to the outer tangent point of the workpiece disk 23 , so that the workpiece disk 23 can also be driven to rotate. The workpiece disc 23 is connected with the overturning system 3, and the overturning system 3 can overturn the workpiece disc 23 by 180°.

[0047] According to the concept of the present invention, the shape of the lens clamping area 2311 is not limited, and besides the above-mentioned rectangle and circle, it can also be a direction or other polygonal shapes. The overturning system 3 can be a rotary cylinder mechanism, a gear drive mechanism or a connecting rod drive mechanism, etc., as long as the mechanism t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com