Method for improving water resistance of magnesium phosphate cement-based material

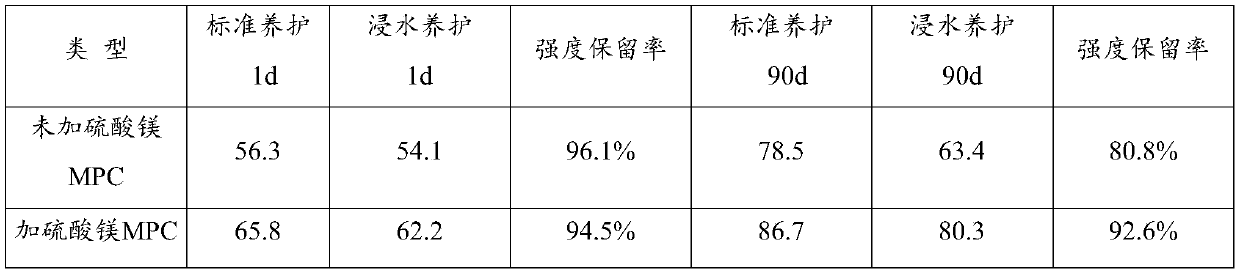

A technology of magnesium phosphate cement and base material, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problems of fast coagulation, loss of water curing strength, etc., to improve the degree of hydration and improve the standard maintenance The effect of improving the compressive strength, compressive strength and retention strength ratio of immersion curing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

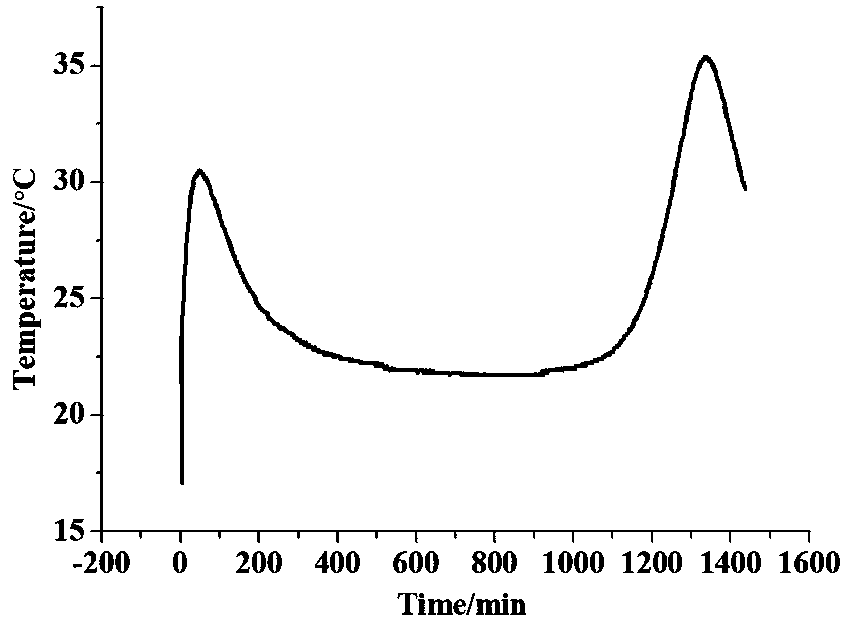

Embodiment 1

[0022] The invention provides a method for improving the water resistance of magnesium phosphate cement-based materials, comprising the following steps:

[0023] Step 1: Take 70 parts by mass of dead-burned magnesia powder and 20 parts by mass of monoammonium phosphate, and add 20 parts by mass of multi-component composite retarder to prepare magnesium phosphate cement-based material powder with a setting time greater than 30 minutes. The multi-component composite retarder is composed of borax and glacial acetic acid, and the mass ratio of each component in the multi-component composite retarder is as follows: borax: glacial acetic acid is 10:1.

[0024] In the first step, the mass ratio of dead-burned magnesium oxide powder, monoammonium phosphate and multi-component composite retarder is not necessarily 70:20:20. The inventor found through a lot of experiments that in order to achieve the purpose of the invention, the mass ratio of dead-burned magnesium oxide powder, monoamm...

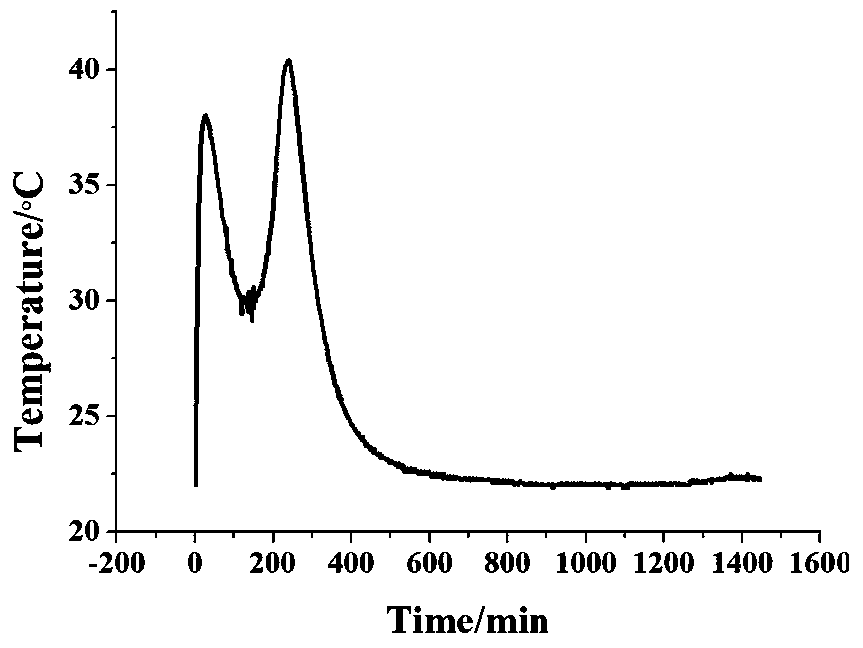

Embodiment 2

[0037] The invention provides a method for improving the water resistance of magnesium phosphate cement-based materials, comprising the following steps:

[0038] Step 1: Take 70 parts by mass of dead-burned magnesia powder and 20 parts by mass of monoammonium phosphate, and add 20 parts by mass of multi-component composite retarder to prepare magnesium phosphate cement with a setting time greater than 30 minutes. The multi-component composite retarder is composed of borax and glacial acetic acid, and the mass ratio of each component in the multi-component composite retarder is as follows: borax: glacial acetic acid is 10:1.

[0039] Step 2, get 100 mass parts of the magnesium phosphate cement base material powder that step 1 makes, the magnesium sulfate (generally being industrial grade) of 1 mass part, the fine aggregate of 150 mass parts and the water of 15 mass parts, fine The aggregate is preferably composed of 1 / 3 to 1 / 2 ordinary river sand. First, add the magnesium phos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com