Dry and wet garbage collection cabinet and dry and wet garbage collection method

A technology of garbage cabinets and collection cabinets, which is applied in the direction of garbage collection, trash cans, instruments, etc., which can solve the problem that dry and wet garbage collection cabinets cannot be traced back to the user's responsibility for wrong delivery, and achieve the effect of raising awareness and facilitating supervision and management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

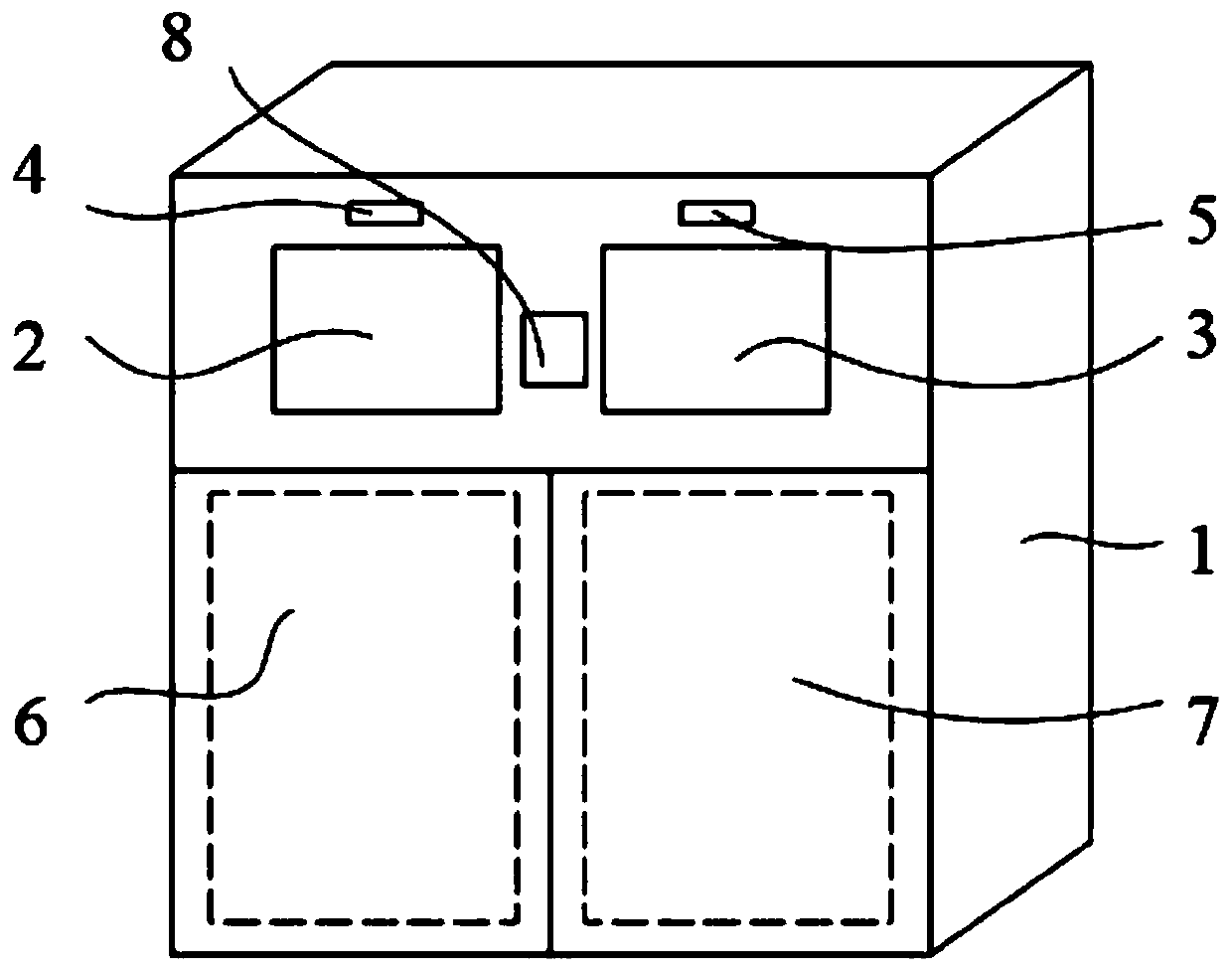

[0029] Such as figure 1 As shown, a kind of dry and wet garbage collection cabinet in this embodiment includes a box body 1, a dry garbage cabinet door 2, a wet garbage cabinet door 3, a first code scanning area 4, a second code scanning area 5, and a dry garbage box 6 and the wet garbage box 7; the dry garbage box 6 and the wet garbage box 7 are box structures with open upper ends, and the box body 1 is provided with a first accommodating cavity and a second accommodating cavity, wherein the first accommodating cavity and the second accommodating cavity There is a dividing plate between the two accommodation chambers, the dry garbage box 6 is arranged in the first accommodation chamber, the open end of the dry garbage box 6 is vertically upward, the wet garbage box 7 is arranged in the second accommodation chamber, and the wet garbage box 7 The open end of the dry garbage box is vertically upward; the dry garbage cabinet door 2 is arranged on the side wall of the box body 1 d...

Embodiment 2

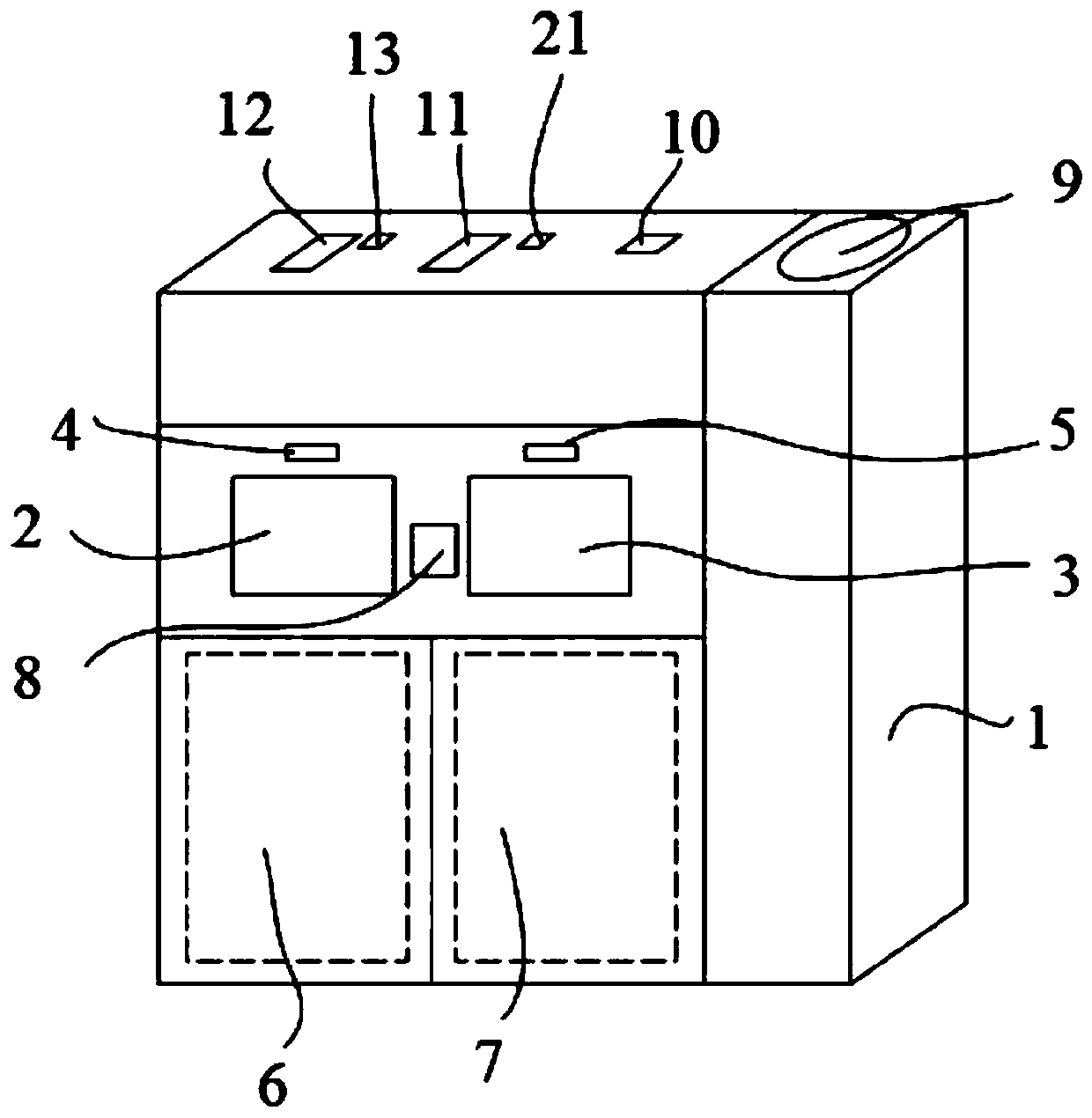

[0032] Such as figure 2and image 3 As shown, a kind of wet and dry garbage collection cabinet in this embodiment includes all the technical features in Embodiment 1, in addition, it also includes a touch screen 8, and the touch screen 8 is arranged on the dry garbage cabinet door 2 and the wet garbage cabinet door 3, the touch screen 8 is used for touch operation to open the dry garbage cabinet door 2 and the wet garbage cabinet door 3, the touch screen 8 adopts the touch screen in the prior art, and its control circuit adopts the setting on the touch screen in the prior art The form of the icon controls the opening of the dry garbage cabinet door 2 and the wet garbage cabinet door 3. For example, two icons of the dry garbage cabinet door 2 and the wet garbage cabinet door 3 are set on the touch screen 8, and the corresponding icons are clicked with fingers to realize the corresponding cabinet door. It also includes an instant noodle barrel input port 9, a third accommodati...

Embodiment 3

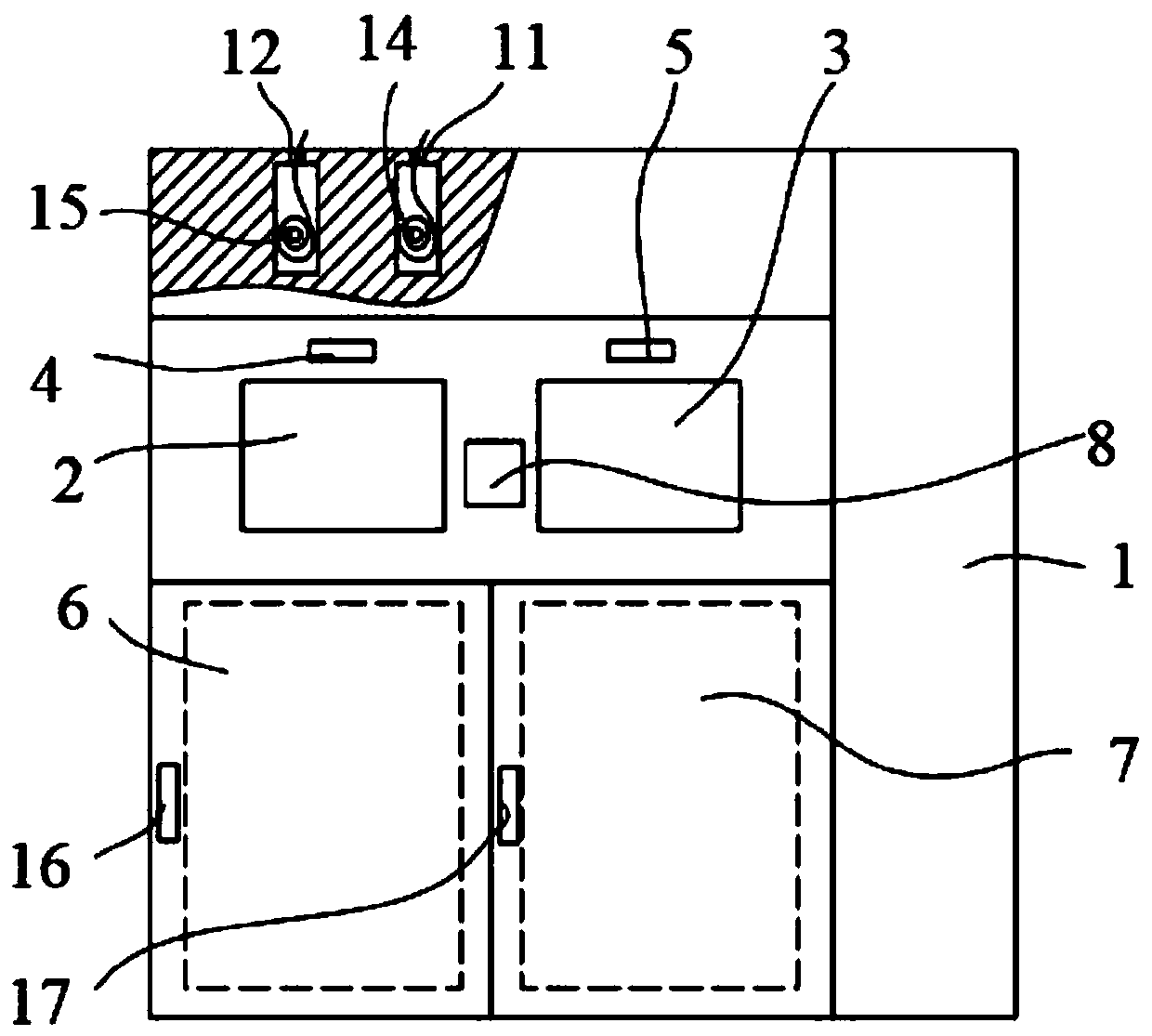

[0035] Such as figure 2 and image 3 As shown, a dry and wet garbage collection cabinet in this embodiment includes all the technical features in Embodiment 2, in addition, it also includes a bag-out scanning code area 10, a dry garbage bag outlet 11 and a wet garbage bag outlet 12. The bag-out scanning area 10 is a two-dimensional code. Scan the two-dimensional code through a mobile client such as WeChat, and an interface for selecting dry garbage bags and wet garbage bags appears. By clicking the corresponding icon, the dry garbage bag and wet garbage bag can be realized For the automatic output of bags, the bag-out scanning code area 10, the dry garbage bag outlet 11 and the wet garbage bag outlet 12 are all arranged on the upper surface of the casing 1; the dry garbage bag reel 14 is arranged directly below the dry garbage bag outlet 11, and Garbage bag reel 14 is rotatably connected on the casing 1, and the shaft end of dry garbage bag reel 14 is connected with first dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com