Novel composite refractory mica tape and manufacturing method thereof

A technology of fire-resistant mica and artificial synthetic mica, which is applied in the field of cables, can solve the problem of no fire-proof cable, etc., and achieve the effects of good fire-resistance performance, reliable fire-proof and insulation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

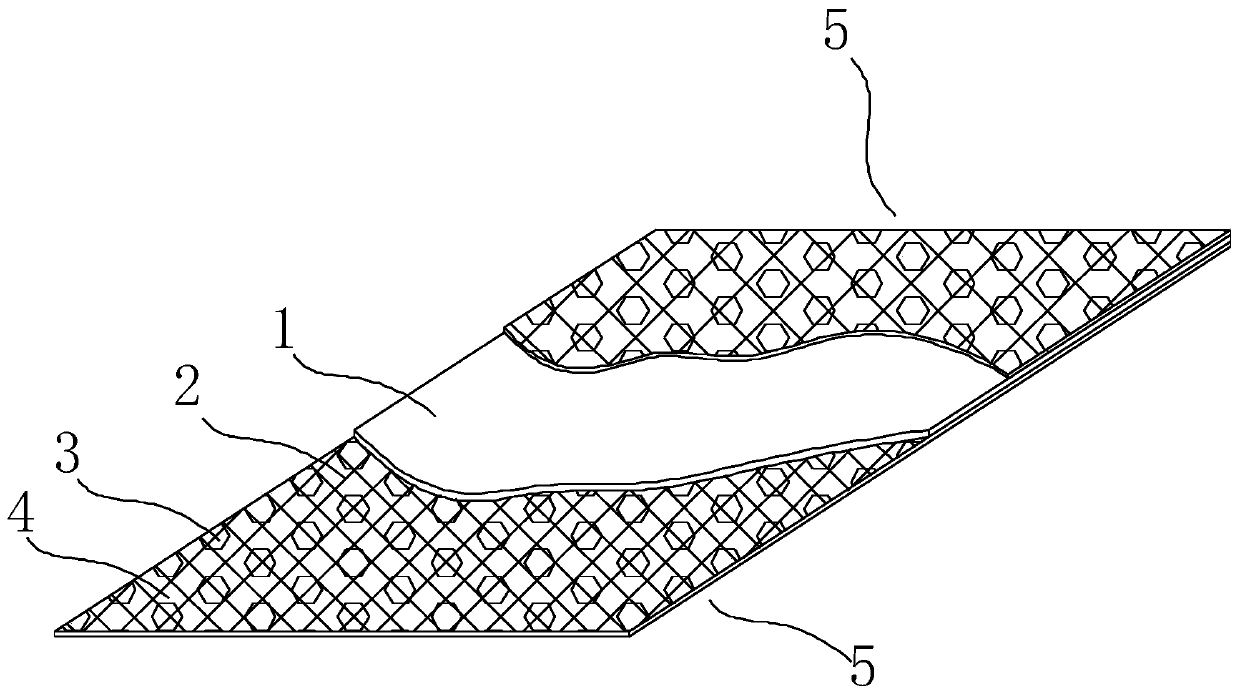

[0031] The thickness of the high-silica glass fiber net 2 is 0.025mm, the mesh number of the high-silica glass fiber net 2 is 200 mesh, the particle diameter of the ceramicized silicone rubber 3 is 0.06mm, and the thickness of the artificial mica paper layer 1 is 0.08mm , the thickness of the silicone resin is 0.02mm.

[0032] Its manufacturing method comprises the following steps:

[0033] includes steps a and b;

[0034] c. Bake the semi-finished product twice successively. The first baking temperature is 100°C, bake for 4 hours, then keep warm for 1.5 hours, and then naturally cool to room temperature, the second baking temperature is 125°C, bake 4 hours, then keep warm for 1.5 hours, then naturally cool to room temperature, and finally obtain the finished product.

Embodiment 2

[0036] The thickness of the high-silica glass fiber net 2 is 0.03mm, the mesh number of the high-silica glass fiber net 2 is 270 mesh, the particle diameter of the ceramicized silicone rubber 3 is 0.07mm, and the thickness of the synthetic mica paper layer 1 is 0.05mm , the thickness of the silicone resin is 0.01mm.

[0037] Its manufacturing method comprises the following steps:

[0038] includes steps a and b;

[0039] c. Bake the semi-finished product twice successively. The first baking temperature is 90°C, bake for 4 hours, then keep warm for 2 hours, and then naturally cool to room temperature, the second baking temperature is 160°C, bake 4 hours, then keep warm for 1.5 hours, then naturally cool to room temperature, and finally obtain the finished product.

Embodiment 3

[0041] The thickness of the high-silica glass fiber net 2 is 0.05mm, the mesh number of the high-silica glass fiber net 2 is 200 mesh, the particle diameter of the ceramicized silicone rubber 3 is 0.07mm, and the thickness of the artificial mica paper layer 1 is 0.10mm , the thickness of the silicone resin is 0.06mm.

[0042] Its manufacturing method comprises the following steps:

[0043] includes steps a and b;

[0044] c. Bake the semi-finished product twice successively. The first baking temperature is 100°C, bake for 4 hours, then keep warm for 2 hours, then cool to room temperature naturally, the second baking temperature is 90°C, bake 4 hours, then keep warm for 1.5 hours, then naturally cool to room temperature, and finally obtain the finished product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com