Grading grinding and polishing device based on composite gradient elastic small tool

A small tool, lapping and polishing technology, applied in the direction of manufacturing tools, abrasive surface adjustment devices, metal processing equipment, etc., can solve the problems of good processing effect, low processing efficiency and automation, material removal characteristics and unstable surface quality, etc. Achieve the effect of improving the processing effect, improving the processing efficiency and simplifying the residence time and the planning of the processing path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0063] The present invention takes a specific embodiment as follows:

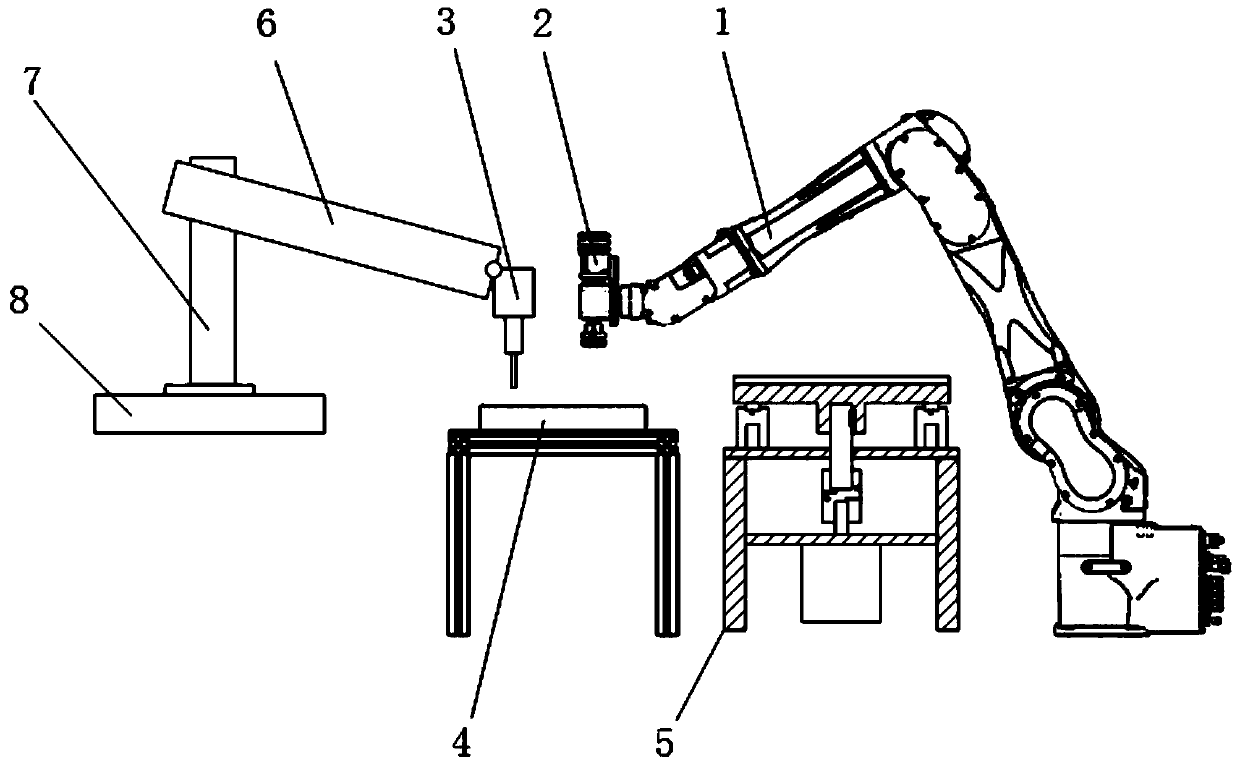

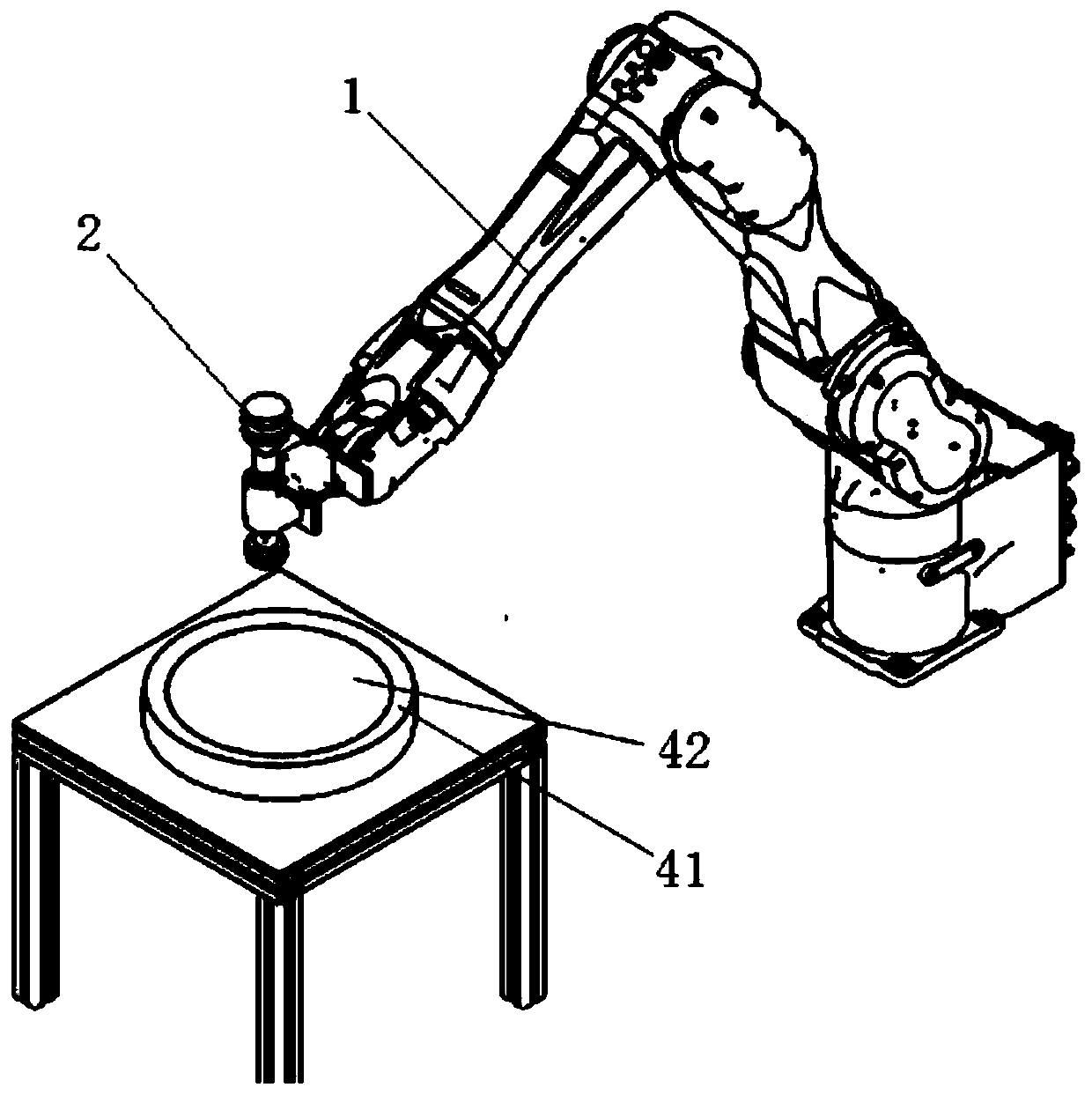

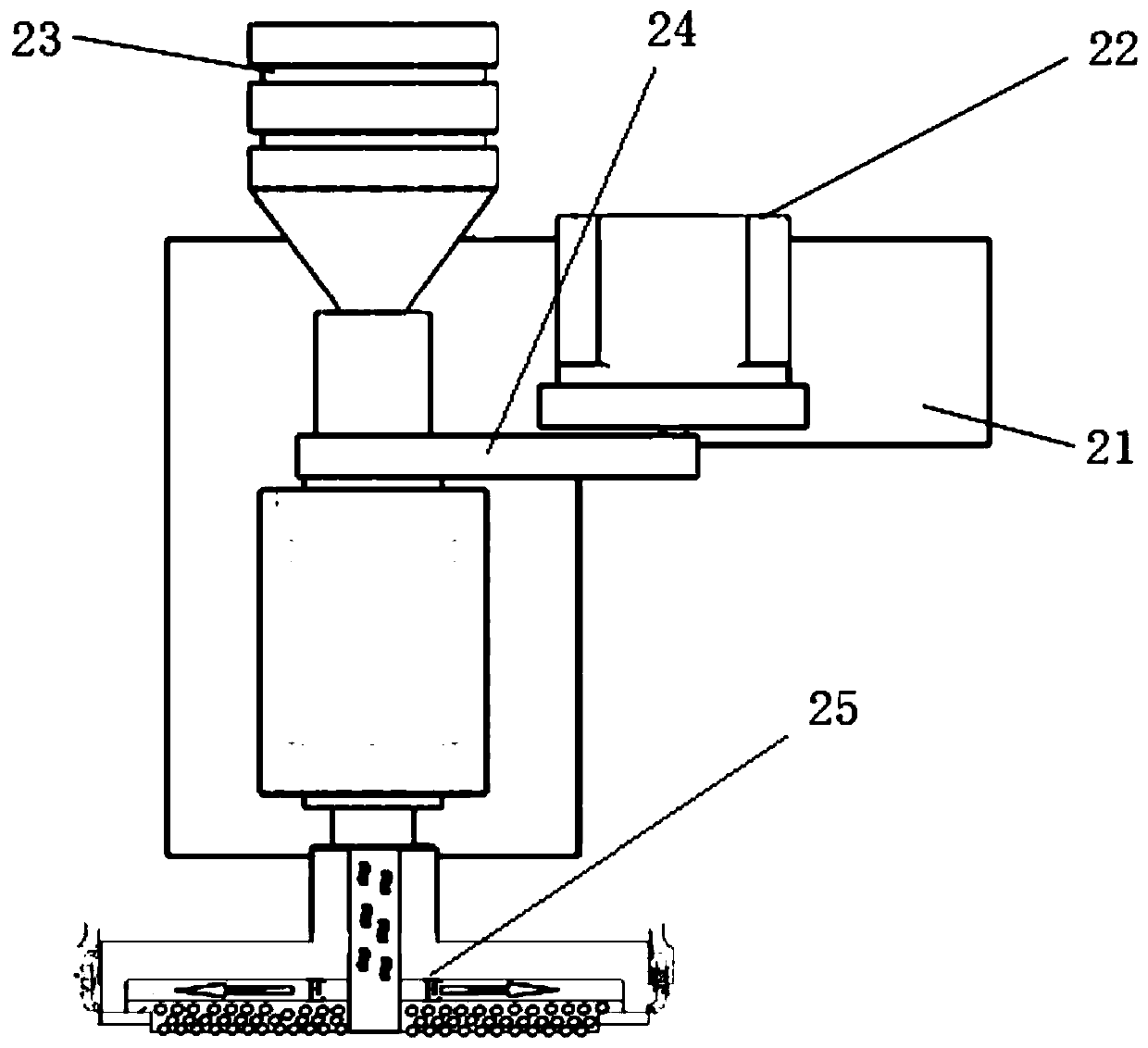

[0064] A graded lapping and polishing device based on a compound gradient elastic small tool, the compound gradient elastic small tool is composed of a rigid layer, a gradient layer and a homogeneous layer. The gradient layer is uniformly mixed with silicone rubber, softener, catalyst and other performance additives and then naturally cured. The preparation method is: weigh 470g of silicone rubber, 48g of softener, and 12g of performance additives. After mixing the above materials, Add the catalyst, mix evenly again, pour into the mold sequentially in the order of 1-3-5 rings and 2-4 rings, the depth of the mold groove is 5 mm, let it naturally ventilate, and obtain a gradient layer after curing for 6 hours; the homogeneous layer is formed by Silicon carbide, silicone rubber, softener, catalyst and other performance additives are evenly mixed, weigh 260g of silicone rubber, weigh 240g of silicon carbide wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com