High-energy beam welding method for dual-metal layered composite board

A high-energy beam welding, bimetallic layered technology, applied in electron beam welding equipment, welding equipment, laser welding equipment and other directions, can solve the problems of affecting the comprehensive performance of joints, serious dilution of composite plates, etc., and achieve a wide range of industrial application prospects and processes. Simple assembly and high joint performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

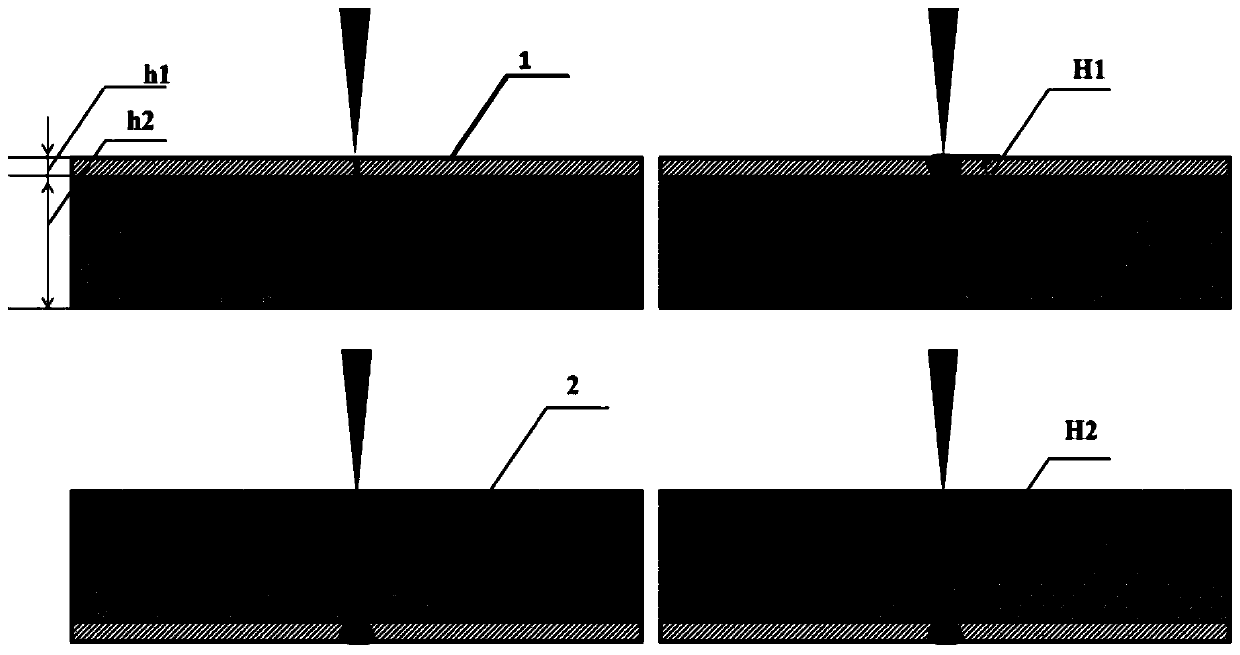

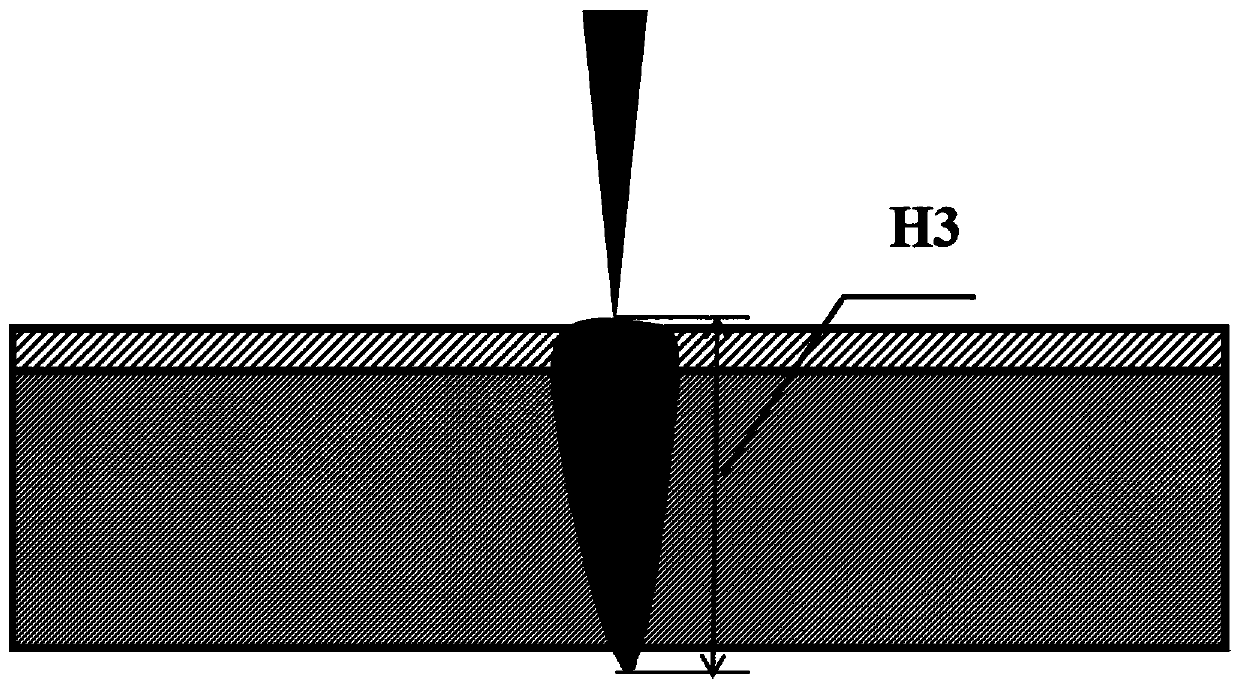

[0027] Such as figure 1 As shown, a kind of 6.0mm thick aluminum-copper bimetallic laminated board is welded by the high energy beam welding method of a kind of bimetallic laminated composite board of the present invention, wherein the thickness h2 of the aluminum substrate is 4.8mm, and the thickness h1 of the copper clad board 1.2mm, the high-energy beam heat source adopts electron beam to carry out welding in the present embodiment, specifically comprises the following steps:

[0028] Step 1: Preparing for High Energy Beam Welding

[0029] Remove the dust and oil on the joint surface of the composite board, and keep the joint surface clean;

[0030] Step 2: Welding of copper composite board in aluminum-copper composite board

[0031] The aluminum-copper composite boards to be welded are tightly butt-jointed, and the side of the doubler board 1 faces the high-energy beam heat source, and then the high-energy beam heat source is used to weld it to realize the welding of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com