Processing technology of anti-aging latex mattress

A processing technology and anti-aging technology, applied in the field of mattresses, can solve the problems of latex layer performance decline, reduce original efficacy, poor anti-aging performance, etc., and achieve the effect of prolonging time, correcting bad sleeping posture, and good anti-aging performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

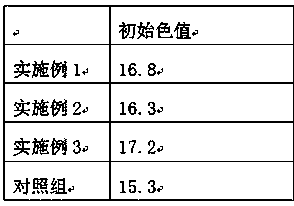

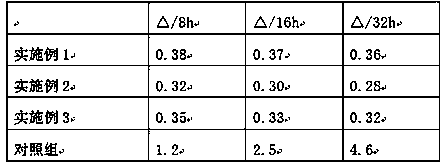

[0020] A kind of aging-resistant latex mattress processing technology, comprises the following steps:

[0021] (1) Preparation of latex layer 2: Add 3% of its mass anionic surfactant to natural latex, stir at 250r / min for 20min at 25°C, and then add 5.5% of natural latex by high-temperature steam fumigation Bamboo charcoal powder, 3% vulcanizing agent, 2% vulcanization accelerator, 1% anti-aging agent, at 30 ℃, stir 30min with 500r / min rotating speed, obtain latex dispersion liquid; The described latex dispersion that obtains The liquid is foamed, and nitrogen is passed into the latex dispersion for foaming, and a curing agent of 5.5% of the latex dispersion quality is added to obtain a foaming material, which is added to the mold and boiled for 55 minutes. Then carry out demoulding, dry and get final product, described anti-aging agent is anti-aging agent 264;

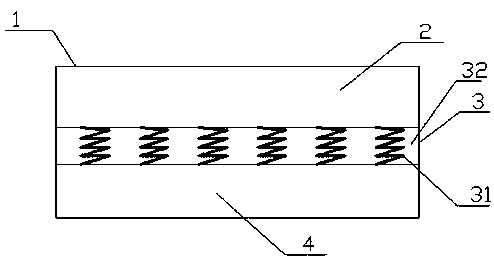

[0022] (2) Preparation of the elastic bamboo charcoal layer 3: the elastic bamboo charcoal layer 3 is composed of ...

Embodiment 2

[0032] A kind of aging-resistant latex mattress processing technology, comprises the following steps:

[0033] (1) Preparation of latex layer 2: Add 5% of its mass anionic surfactant to natural latex, stir at 250r / min for 25min at 30°C, and then add 5.8% of natural latex by high-temperature steam fumigation Bamboo charcoal powder, 4% vulcanizing agent, 3% vulcanization accelerator, 2% anti-aging agent, at 35 ℃, stir 30min with 500r / min rotating speed, obtain latex dispersion liquid; The described latex dispersion that obtains The liquid is foamed, and nitrogen is passed into the latex dispersion for foaming, and a curing agent of 6% of the latex dispersion is added to obtain a foam, which is added to the mold and boiled for 60 minutes. Then carry out demoulding, dry and get final product, described anti-aging agent is anti-aging agent 264;

[0034] (2) Preparation of the elastic bamboo charcoal layer 3: the elastic bamboo charcoal layer 3 is composed of bamboo charcoal powder...

Embodiment 3

[0044] A kind of aging-resistant latex mattress processing technology, comprises the following steps:

[0045] (1) Preparation of latex layer 2: After adding 3-5% of its mass anionic surfactant to the natural latex, stir at 250r / min for 22min at 28°C, and then add high-temperature steam passing through 5.6% of the mass of natural latex Fumigation modified bamboo charcoal powder, 3.5% vulcanizing agent, 2.5% vulcanization accelerator, 1.5% anti-aging agent, at 32°C, stirred for 30min at a speed of 500r / min to obtain a latex dispersion; the obtained The latex dispersion is foamed, and nitrogen is passed into the latex dispersion for foaming, and a curing agent of 5.6% of the latex dispersion quality is added to obtain a foaming material, which is added to the mold and boiled 58min, then carry out demoulding, dry and get final product, described anti-aging agent is anti-aging agent 264;

[0046] (2) Preparation of the elastic bamboo charcoal layer 3: the elastic bamboo charcoal la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com