Residual current mutual inductor and assembling technology thereof

A residual current and assembly process technology, applied in the field of transformers, can solve the problems of transformer performance degradation, performance degradation, and complicated installation, and achieve the effect of convenient later transformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

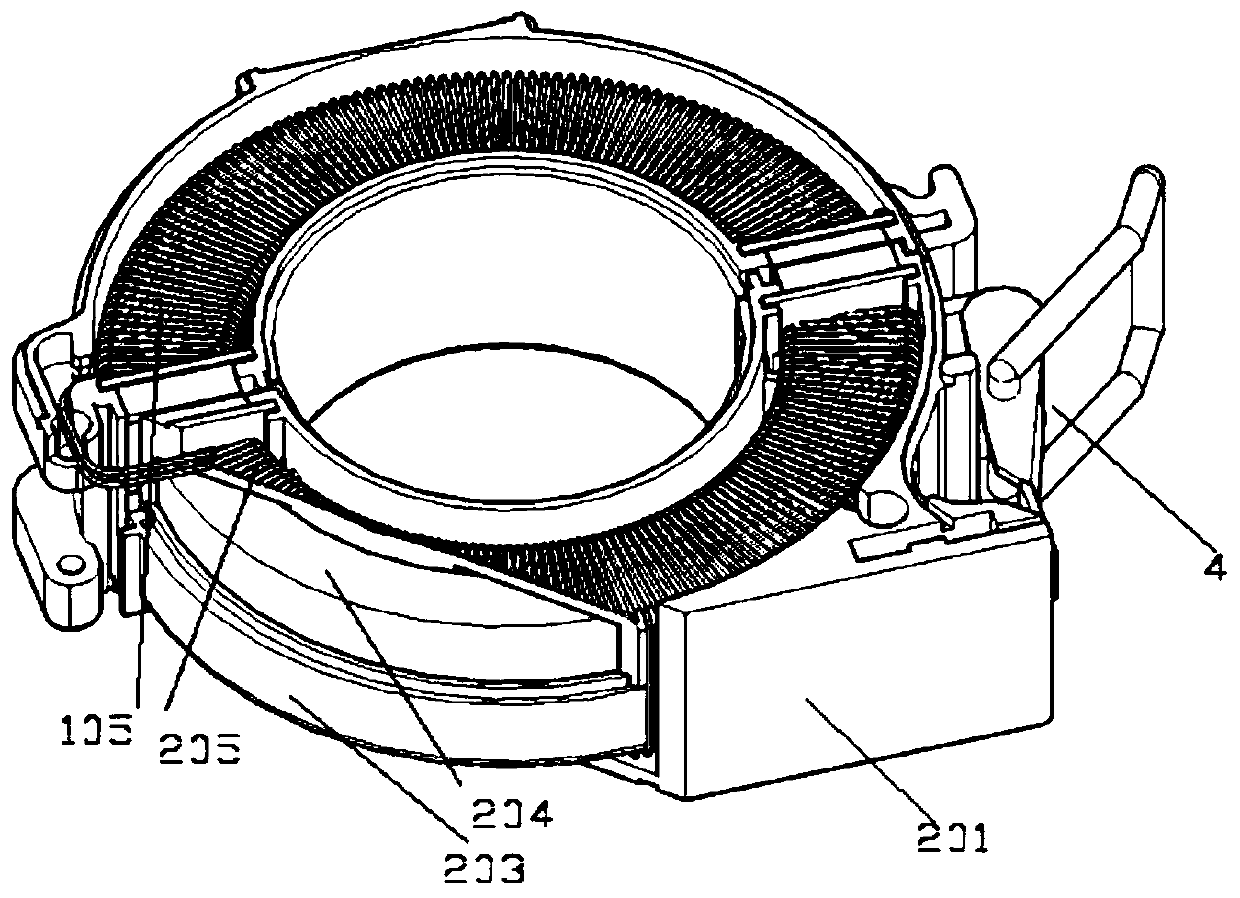

[0035] see Figure 1-19 , a residual current transformer related to the present invention, the residual current transformer includes an upper half ring 1 and a lower half ring 2, the left end of the upper half ring 1 and the left end of the lower half ring 2 are connected through a pin shaft 3 Hinged, the right end of the upper half ring 1 is connected with the right end of the lower half ring 2 through a buckle 4;

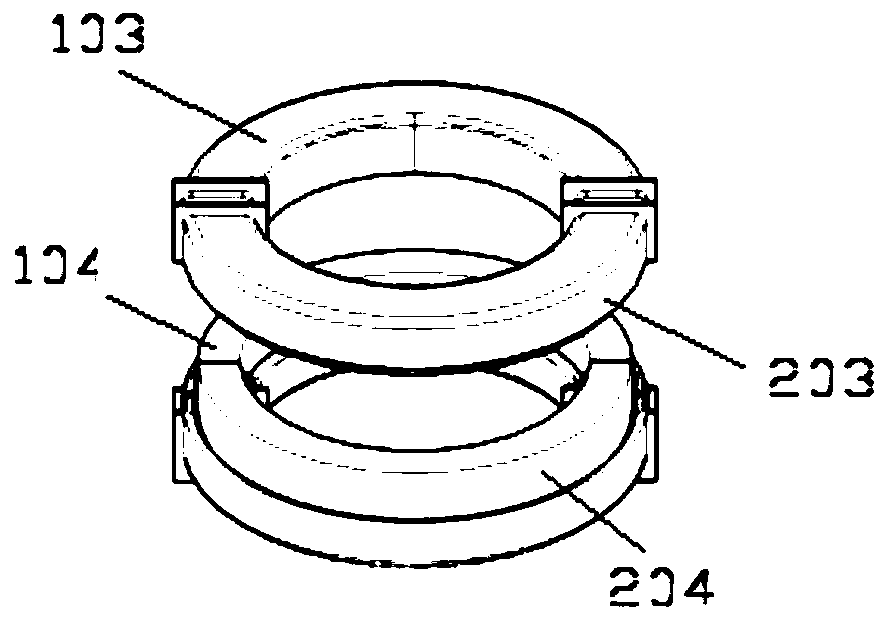

[0036] The upper half ring 1 includes an upper iron core assembly 102 installed in the upper casing 101, and the upper iron core assembly 102 includes an upper half iron core 104 installed in an upper frame 103, on which the upper frame 103 Wound with an upper winding group 105;

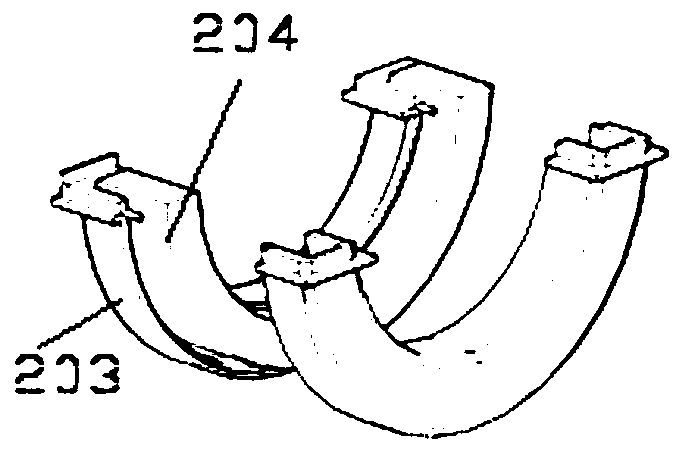

[0037] The lower half ring 2 includes a lower iron core assembly 202 installed in the lower casing 201, and the lower iron core assembly 202 includes a lower half iron core 204 installed in the lower frame 203, on which the lower frame 203 The lower winding group 105 is wound; and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com