High-precision infrared radiation measuring method

A technology of infrared radiation and measurement method, applied in the field of infrared system radiation measurement, can solve the problems of low calibration data accuracy, large radiation calibration workload, poor measurement accuracy, etc., and achieve the effect of improving the system radiation measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

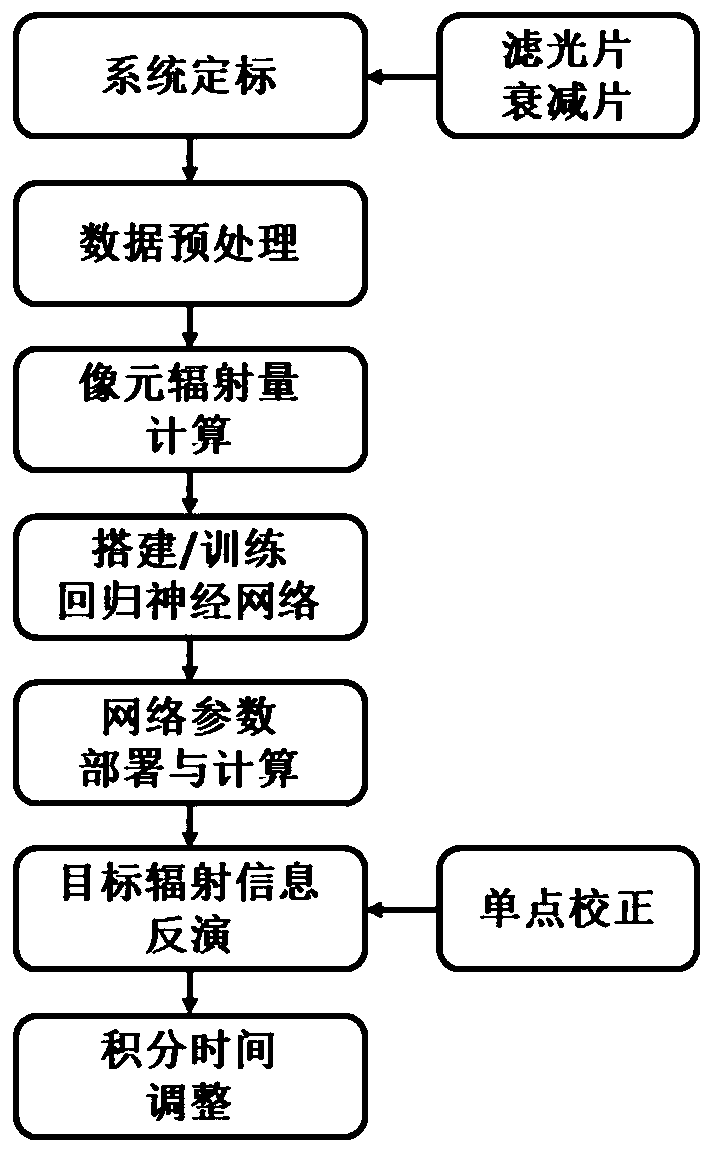

[0064] Such as figure 1 Shown, a kind of high-precision infrared radiation measuring method of the present invention, concrete steps are as follows:

[0065] Step A, system calibration: Calibrate the working point at multiple attenuation slices, integration time, and blackbody temperature points in the system, and obtain multiple frames of raw data of image grayscale response changing with integration time and blackbody temperature.

[0066] Step B, data preprocessing: performing average denoising and blind element replacement preprocessing on the multi-frame raw data of each working point. The effect picture after average denoising and blind element processing in this embodiment is as follows figure 2 shown;

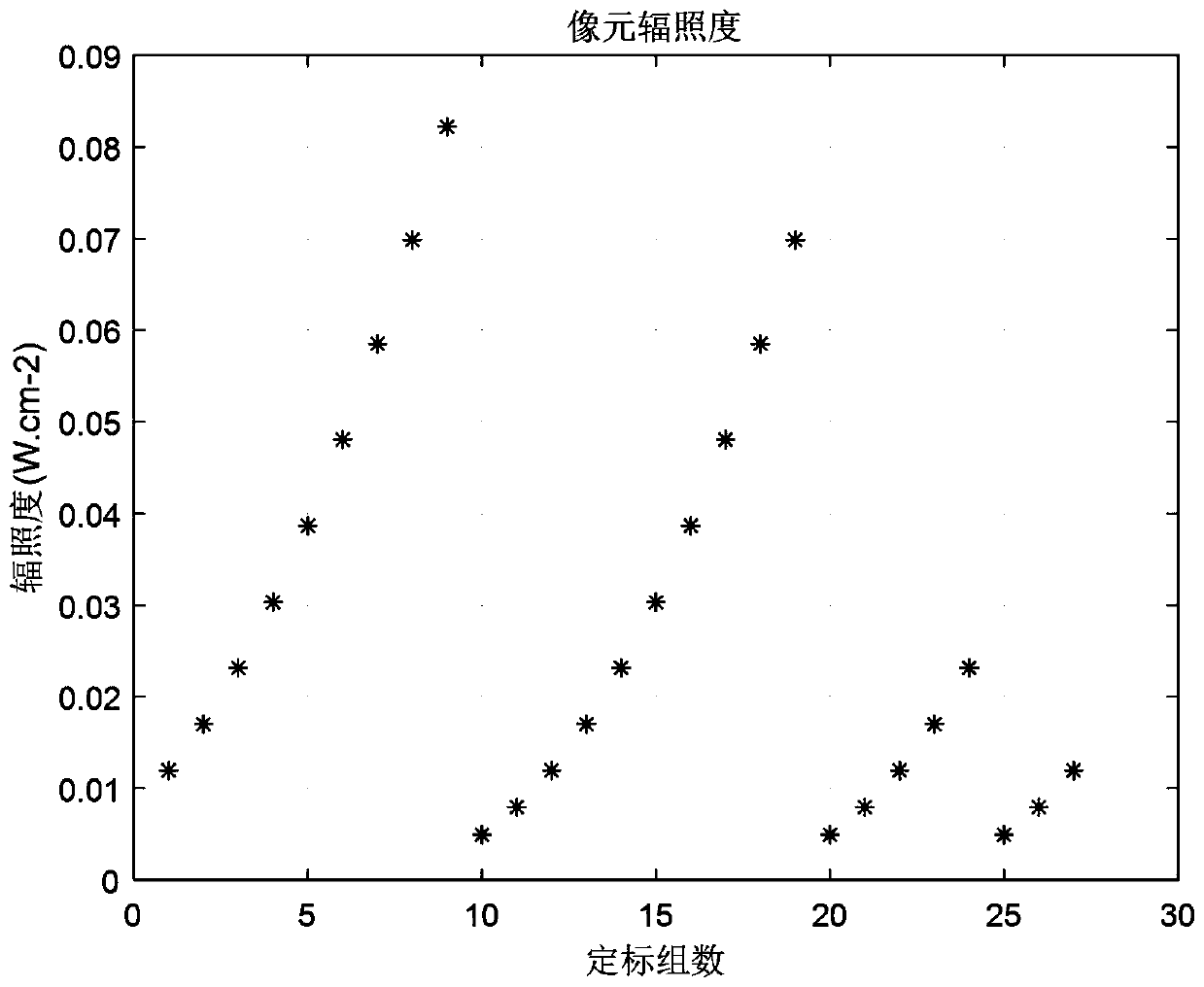

[0067] Step C, calculation of pixel irradiance: taking the pixel irradiance as an example, according to the Planck blackbody radiation form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com