Catalytic combustion all-in-one machine

A catalytic combustion, all-in-one technology, applied in the combustion method, combustion type, incinerator and other directions, can solve the problems of high cost and complex structure of the catalytic combustion device, and achieve the effects of low manufacturing and processing cost, easy handling and installation, and improved efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

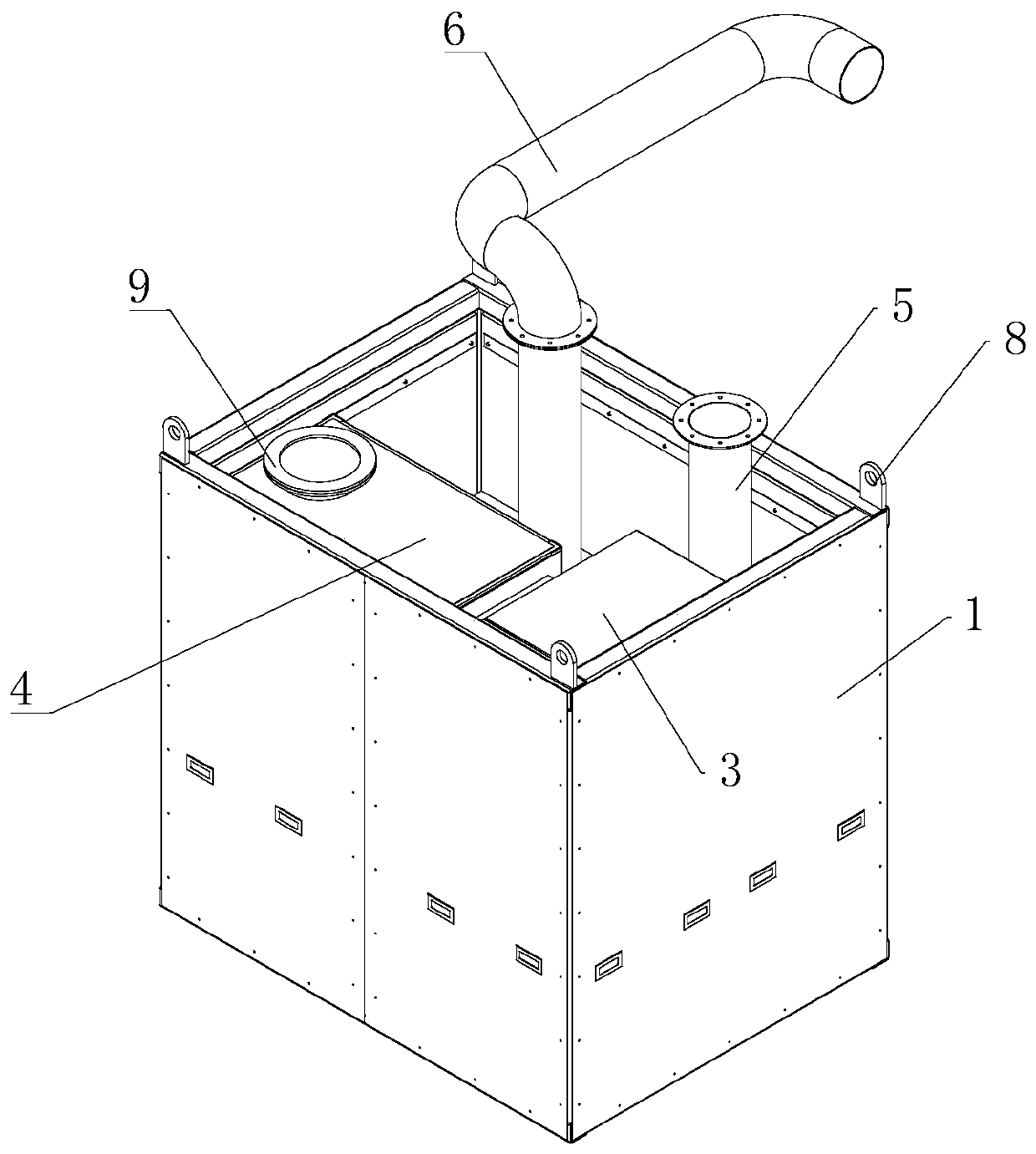

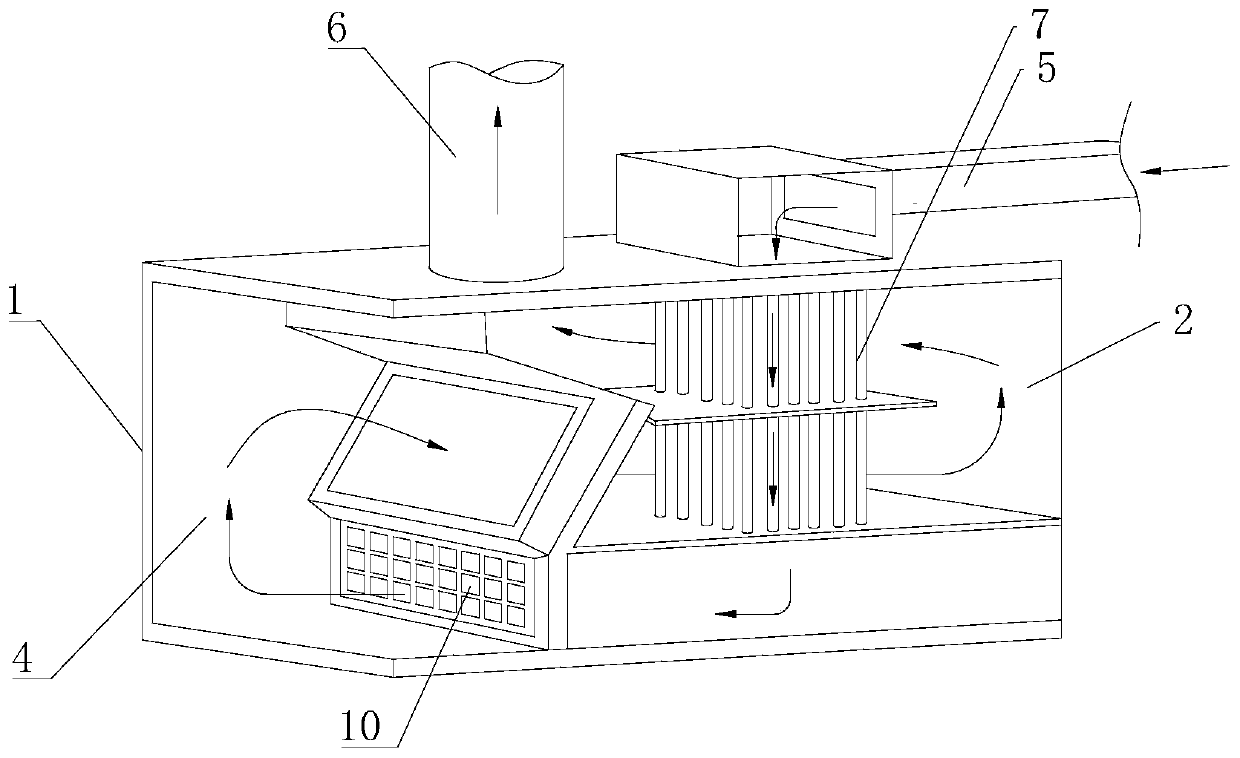

[0031] Such as figure 1 with figure 2 As shown, they are the structural diagram and schematic diagram of the catalytic combustion integrated machine of the present invention, respectively. The integrated machine first includes a body shell 1, and a body heat exchange chamber 2, an electric heating chamber 3, and a catalytic combustion chamber 4 are arranged inside the body shell 1. , and the exhaust gas inlet 5 and the gas outlet 6 are also connected to the body shell 1 at the same time. The basic working principle of this all-in-one machine is: the exhaust gas to be treated enters from the exhaust gas inlet 5, and then passes through the body heat exchange chamber 2 and the electric heating chamber 3 in turn, and the exhaust gas in the body heat exchange chamber 2 and electric heating chamber 3 can absorb heat to achieve Preheat, increase its temperature, and prepare for the subsequent catalytic combustion. After that, the waste gas enters the catalytic combustion chamber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com