Encoder-based locomotive positioning device

A positioning device and encoder technology, which is applied to locomotives, railway signals and safety, etc., can solve problems such as hidden dangers in production safety, difficult installation locations, and errors in locomotive positioning accuracy, so as to ensure smooth progress and avoid potential safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

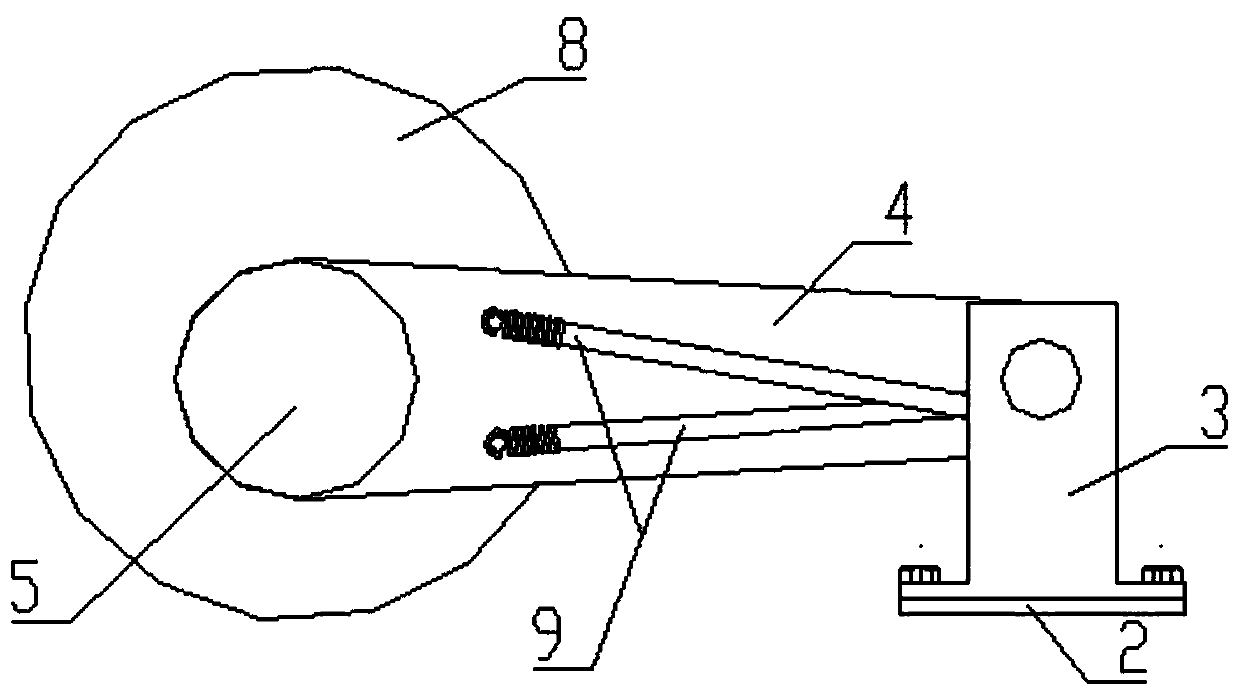

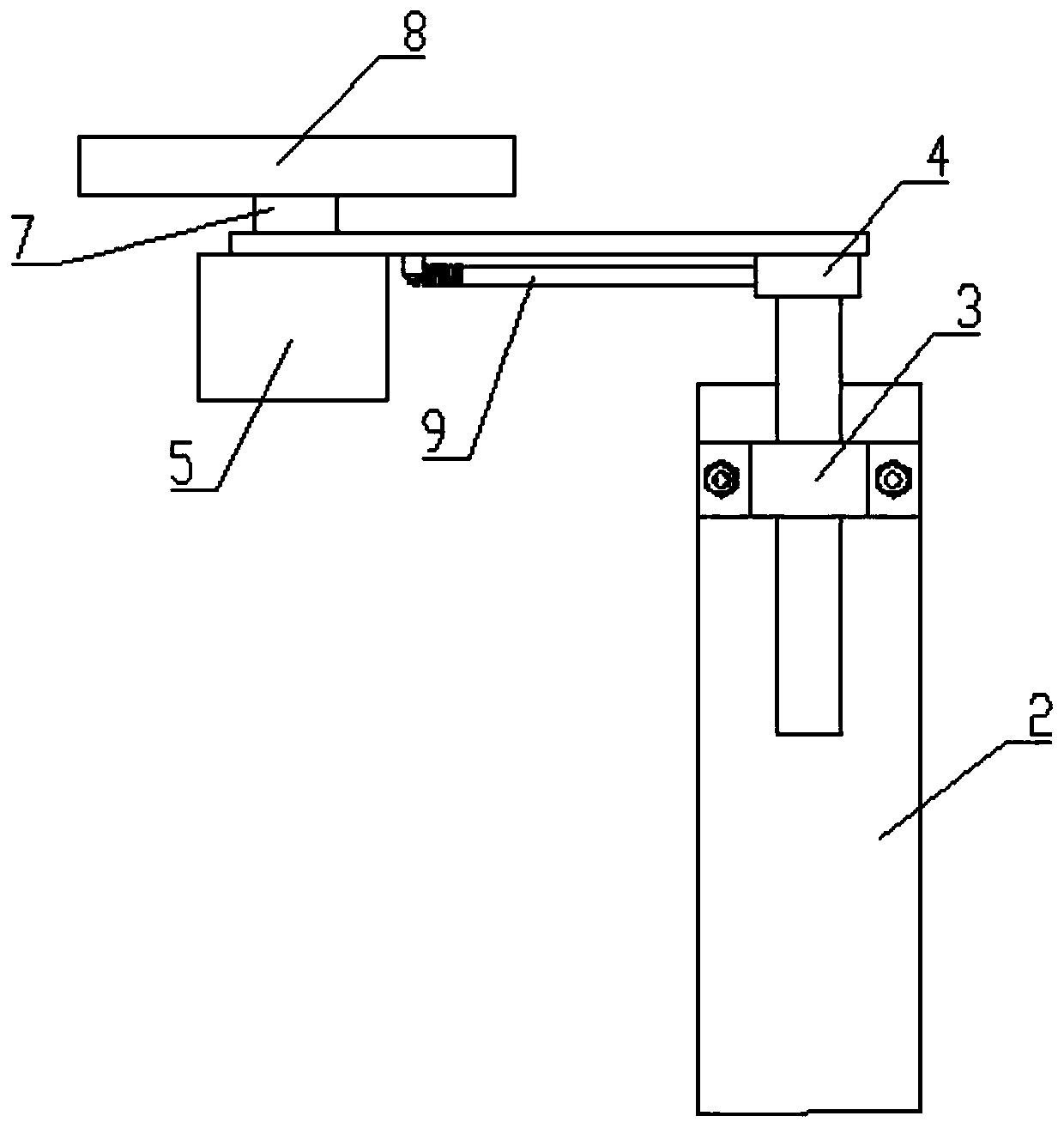

[0017] In the following, the present invention will be further described in detail with reference to the accompanying drawings to facilitate a clearer understanding by those skilled in the art, such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the present invention adopts the following solutions, including:

[0018] The horizontal bracket 2 is installed on the locomotive wheel axle sheath 1. One end of the horizontal bracket is connected to the vertical bracket 3; the swing arm 4 connected to the upper end of the vertical bracket is rotated, and one side of the end of the swing arm is connected to the encoder 5, which is electrically connected The communication cable 6 transmits the data of the encoder to the locomotive controller. The end of the swing arm is rotatably connected to the driven axle 7. One end of the driven axle is matched with the encoder, and the other end of the driven axle is fixed The driven wheel 8 is connected; the end of the swing arm is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com