A method for collecting zinc powder in metallurgical ash

A zinc powder and collection system technology, which is applied in the field of metallurgical solid waste recycling, can solve the problems of direct condensation and collection of zinc powder, high consumption of leaching agents, and little research on methods, so as to improve the utilization rate of raw materials and prevent zinc vapor Loss, effect of improving collection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

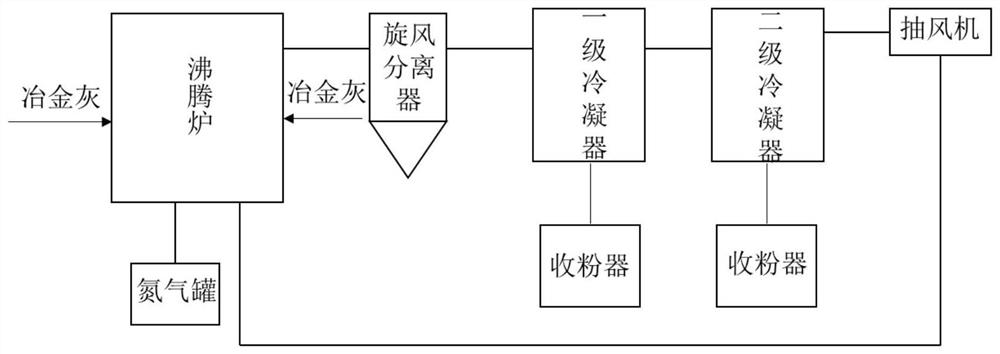

[0041]This embodiment adopts a circulating zinc powder collection system to extract and collect zinc powder in metallurgical ash, including a boiling furnace, a cyclone separator, a primary condenser, a secondary condenser powder collector, a nitrogen tank and an exhaust fan. The cyclone separator is connected with the boiling furnace and the primary condenser, the nitrogen gas in the nitrogen tank is blown from the bottom of the boiling furnace, and the exhaust fan includes two air guide pipes, one is connected with the bottom of the boiling furnace, and the other is connected with the waste gas collection tank, so The nitrogen tank also includes a nitrogen heating device.

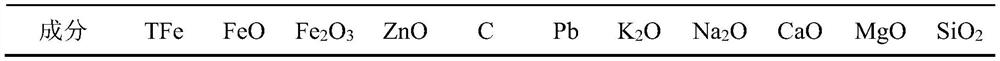

[0042] The raw materials used in this example are metallurgical ash discharged from a steel plant, and the main chemical components of the samples are shown in Table 1.

[0043] Table 1 Mass content of main chemical components of metallurgical ash in a steel plant

[0044]

[0045]

[0046] S1. Wei...

Embodiment 2

[0054] This embodiment uses a circulating zinc powder collection system to extract and collect zinc powder in metallurgical ash, including a boiling furnace, a cyclone, a primary condenser, a secondary condenser powder collector, a nitrogen tank, a vacuum pump, a pressure gauge and Exhaust fan. The cyclone separator is connected with the boiling furnace and the primary condenser, the nitrogen gas in the nitrogen tank is blown from the bottom of the boiling furnace, and the exhaust fan includes two air guide pipes, one is connected with the bottom of the boiling furnace, and the other is connected with the waste gas collection tank, so The nitrogen tank also includes a nitrogen heating device.

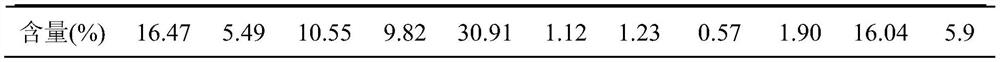

[0055] The raw material used in this example is metallurgical ash discharged from a steel plant, and the main chemical components of the samples are shown in Table 2.

[0056] Table 2 Mass content of main chemical components of metallurgical ash in a steel plant

[0057]

[0058] S...

Embodiment 3-12

[0064] Compared with Example 2, the difference between Examples 3-12 is that the conditions of steps S1 and S2 are as shown in Table 3, and the rest are the same as those of Example 1.

[0065] Table 3 embodiment 3-12 zinc powder collection system conditions

[0066]

[0067] The dezincification rate of metallurgical ash and the purity of zinc powder collected in Examples 3-12 are shown in Table 4. It can be seen that within the conditions specified in the present invention, the dezincification rate and the purity of zinc powder are both high. The high temperature nitrogen temperature has a certain influence on the dezincification rate, but has little effect on the purity of the zinc powder. When the nitrogen temperature decreases, the dezincification rate is slightly lower. This is because the zinc vapor is easier to volatilize and remove under sufficient vapor pressure, and the nitrogen temperature When the heating rate of the boiling furnace is increased, the dezincifica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com