Deep city sludge dehydration curing method

A solidification method and deep dehydration technology, applied in chemical instruments and methods, water/sludge/sewage treatment, sludge treatment, etc., can solve the problem of affecting system processing efficiency, large wear of pumps and pipelines, increased cost and land occupation, etc. problems, to achieve the effect of reducing environmental pollution, strong reliability, and good dehydration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

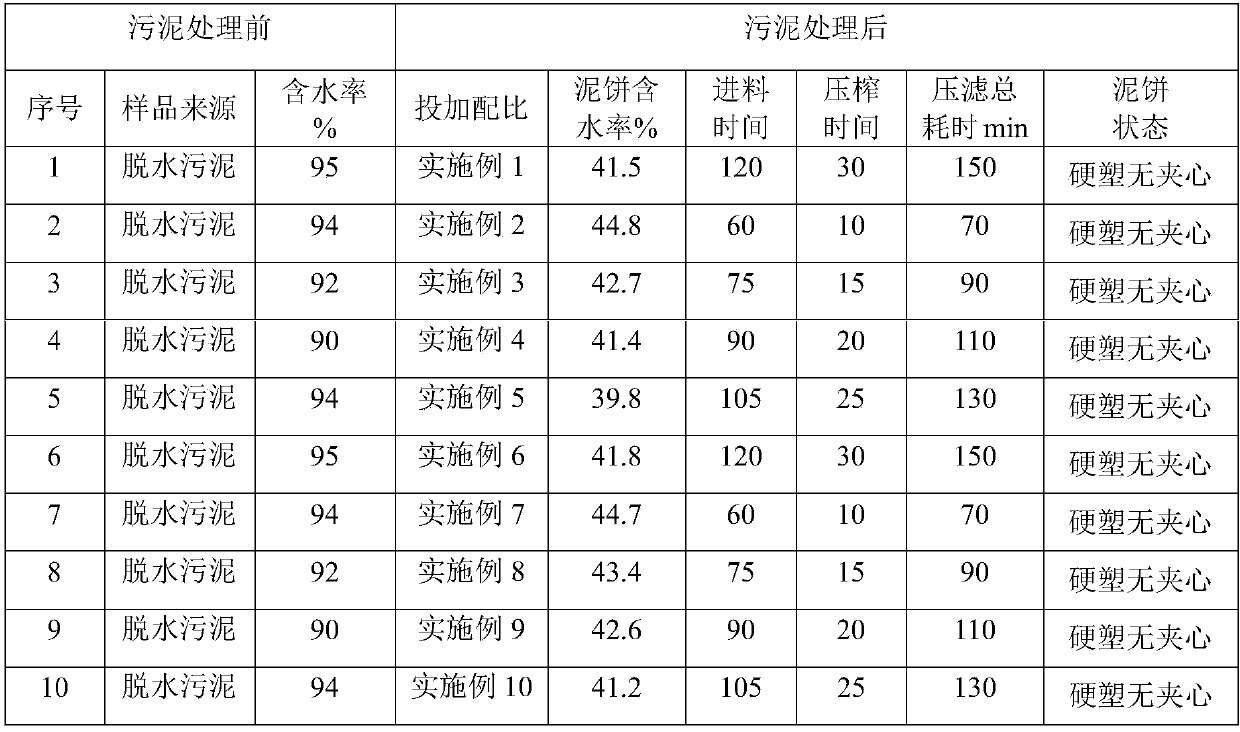

Examples

Embodiment 1

[0050] The municipal sludge deep dehydration solidifying agent and its dehydration solidification method of the present embodiment are carried out according to the following steps:

[0051] 1) Sludge from a sewage plant (dewatered sludge from preliminary dehydration treatment) is pumped into a sludge mixing agitator through a delivery pump, water is added to adjust the moisture content of the sludge to 95%, and the sludge is mixed evenly;

[0052] 2) Mix quicklime with 15% dry sludge content and fly ash with 15% dry sludge content, add water to make a slurry, put the above slurry into a sludge mixing mixer, and stir evenly; then put Add water to iron salt in a ratio of 1:1 to 2 to make a solution, put the iron salt solution into a mixing agitator, and stir evenly. The iron salt is ferric chloride, and the dosage accounts for 5% of the absolute dry sludge. %;

[0053] 3) Put the conditioned sludge into the plate and frame filter press through the feed pump (piston pump) for de...

Embodiment 2

[0055] The municipal sludge deep dehydration solidifying agent and its dehydration solidification method of the present embodiment are carried out according to the following steps:

[0056] 1) Sludge from a sewage plant (dewatered sludge from preliminary dehydration treatment) is pumped into a sludge mixing agitator through a delivery pump, water is added to adjust the moisture content of the sludge to 94%, and the sludge is stirred evenly;

[0057] 2) Mix quicklime with 25% dry sludge content and fly ash with 12.5% dry sludge content, add water to make a slurry, put the above slurry into a sludge mixing mixer, and stir evenly; then put Add water to iron salt in a ratio of 1:1 to 2 to make a solution, put the iron salt solution into a mixing agitator, and stir evenly. The iron salt is ferric sulfate, and the dosage accounts for 3% of the absolute dry sludge amount;

[0058] 3) Put the conditioned sludge into the plate and frame filter press through the feed pump (piston pump...

Embodiment 3

[0060] The municipal sludge deep dehydration solidifying agent and its dehydration solidification method of the present embodiment are carried out according to the following steps:

[0061] 1) Sludge from a sewage plant (dewatered sludge from preliminary dehydration treatment) is pumped into a sludge mixing agitator through a delivery pump, water is added to adjust the moisture content of the sludge to 92%, and the mixture is stirred;

[0062] 2) Mix quicklime with 30% dry sludge content and fly ash with 10% dry sludge content, add water to make a slurry, put the above slurry into a sludge mixing mixer, and stir evenly; then put Iron salt is prepared by adding water in a ratio of 1:1 to 2 to make a solution, put the iron salt solution into a mixing agitator, and stir evenly. The iron salt is a mixed iron salt of ferric sulfate and polyferric sulfate, and the dosage is absolutely 1% of the dry sludge volume;

[0063] 3) Put the conditioned sludge into the plate and frame filte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com