A dynamic mooring system for docks

A dynamic system and dock technology, applied in the direction of ships, etc., can solve the problems of cable grinding and uneven force on mooring cables, and achieve the effect of reducing operation and labor intensity, optimizing the force of mooring cables, and reducing wear and tear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

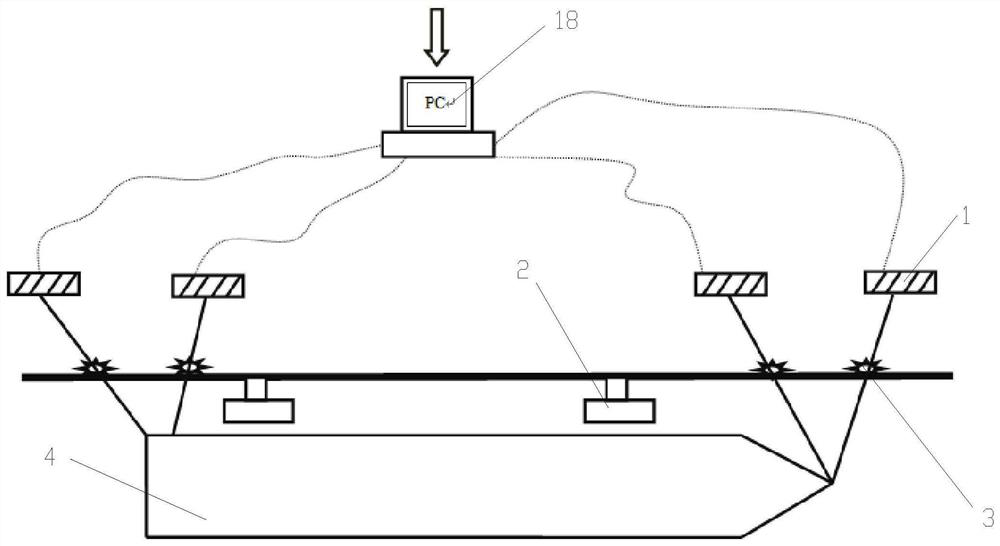

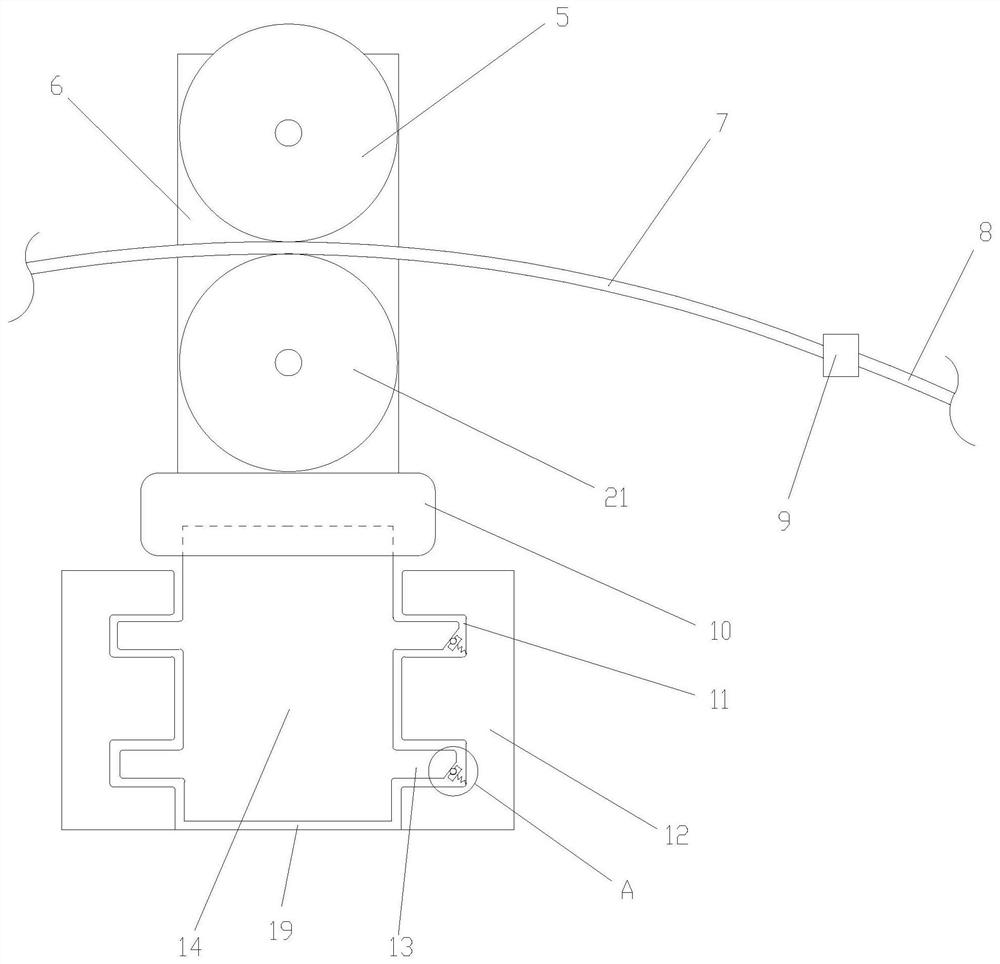

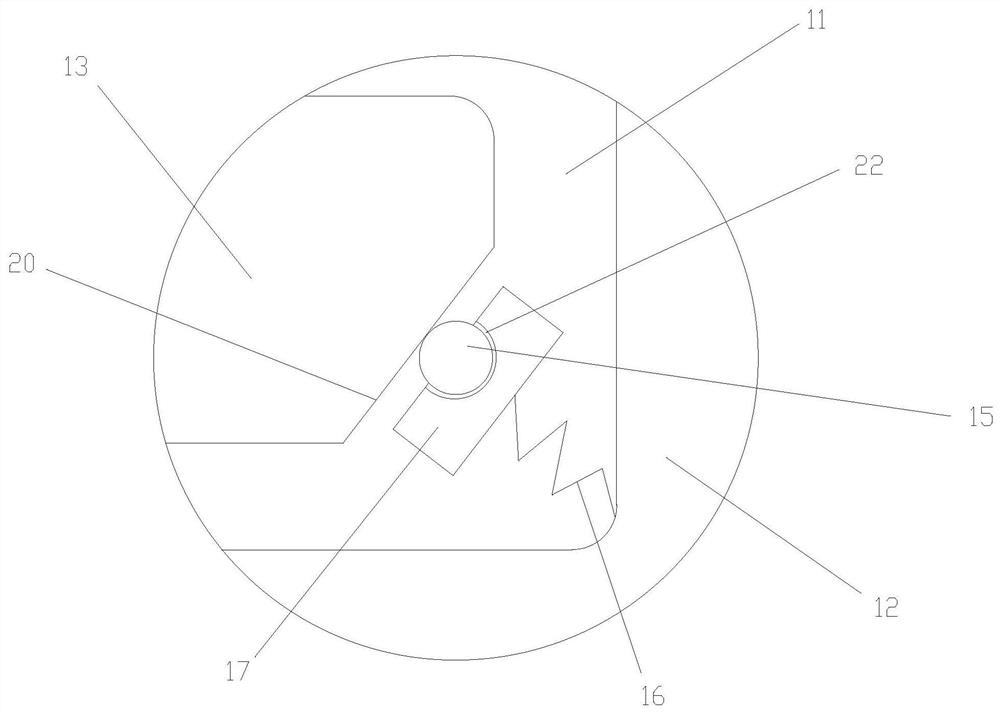

[0026] Such as figure 1 , 2As shown, a dynamic mooring system for a wharf includes a special mooring device 3 and an automatic cable winch 1 connected to a computer control system 18. The automatic cable winch 1 is controlled by a computer control system 18, and the computer control system 18 controls The mooring force is set according to the coastal conditions and the situation of the ship 4, and the tension of the automatic cable winch 1 is adjusted. The special mooring device 3 includes a base 12 arranged on the wharf. The base 12 is arranged horizontally parallel to the front edge of the wharf. 12 is provided with a chute 19, the chute 19 is slidably connected with a sliding core 14, the sliding core 14 can slide in the chute 19, the number of sliding cores 14 is multiple, arranged according to actual needs, the top of the sliding core 14 rotates Connected with a steering seat 10, the steering seat 10 can rotate on the top of the sliding core 14, the steering seat 10 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com