A multi-station fixture for PCB board welding

A PCB board and multi-station technology, applied in the field of tooling and fixtures, can solve problems such as easy shaking of PCB boards during processing, cumbersome process of replacing PCB boards, wrong soldering of component pins, etc., to shorten the clamping time and increase the unit The amount of workpieces processed each time, the effect of accurate and reliable processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

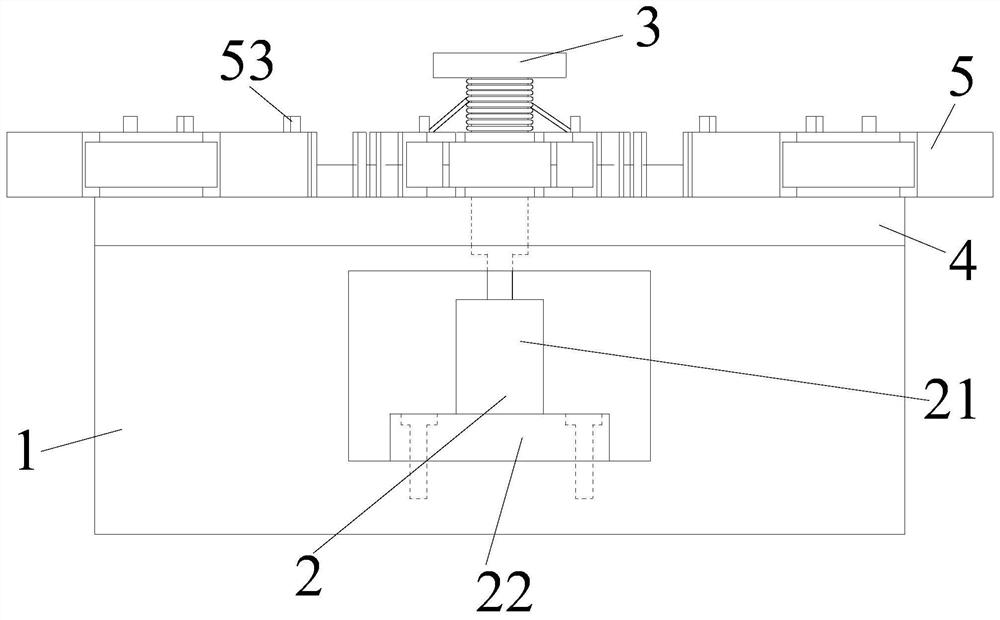

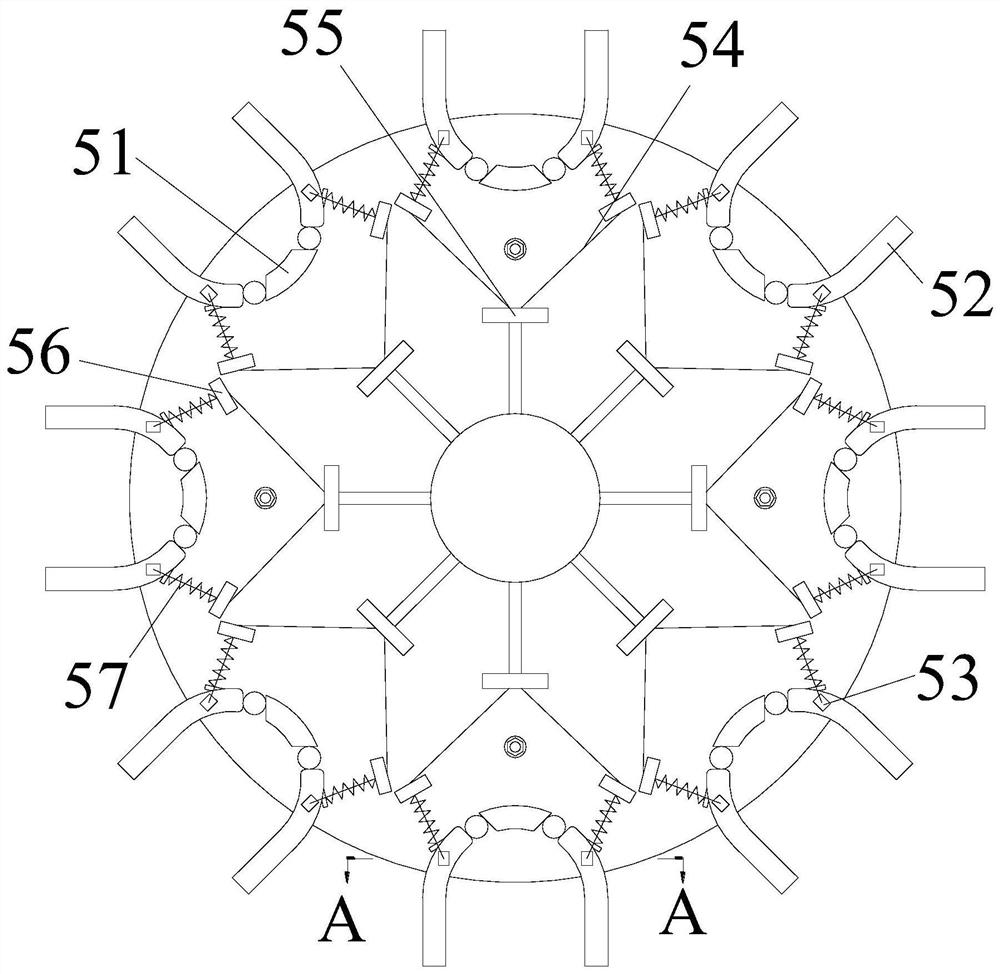

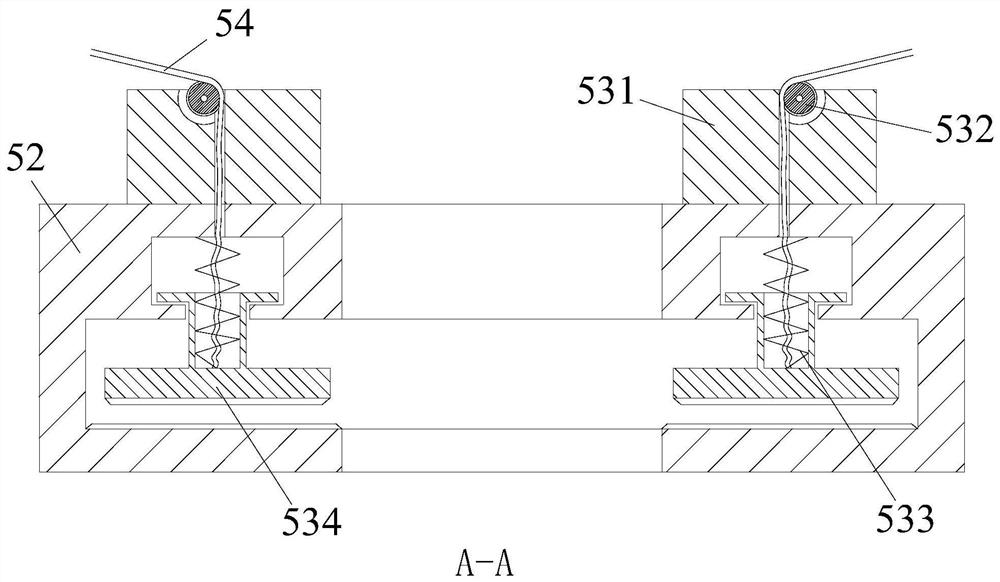

[0028] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the following combination Figure 1 to Figure 7 , to further elaborate the present invention.

[0029] A multi-station fixture for PCB board welding, comprising a workbench 1, a drive device 2, a rotating shaft 3, a mounting plate 4 and a clamping device 5, a drive device 2 is installed inside the workbench 1, and a drive device 2 is installed on the upper end of the drive device 2 The rotating shaft 3 and the upper end of the workbench 1 are equipped with a mounting plate 4, and the mounting plate 4 is evenly arranged with a clamping device 5 along its circumference; wherein:

[0030] The clamping device 5 includes a clamping seat 51, two clamping arms 52, two clamping mechanisms 53, two wire ropes 54, a converging mechanism 55, two steering mechanisms 56 and two compression springs 57, clamping The seat 51 is welded on the outside of the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com