Realization method for preventing damage of core of cable wire

A realization method and cable technology, applied in the direction of cable installation, dismantling/armored cable equipment, cable installation device, etc., can solve the problems of cable damage, staff difficulty, danger, etc., and achieve the effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

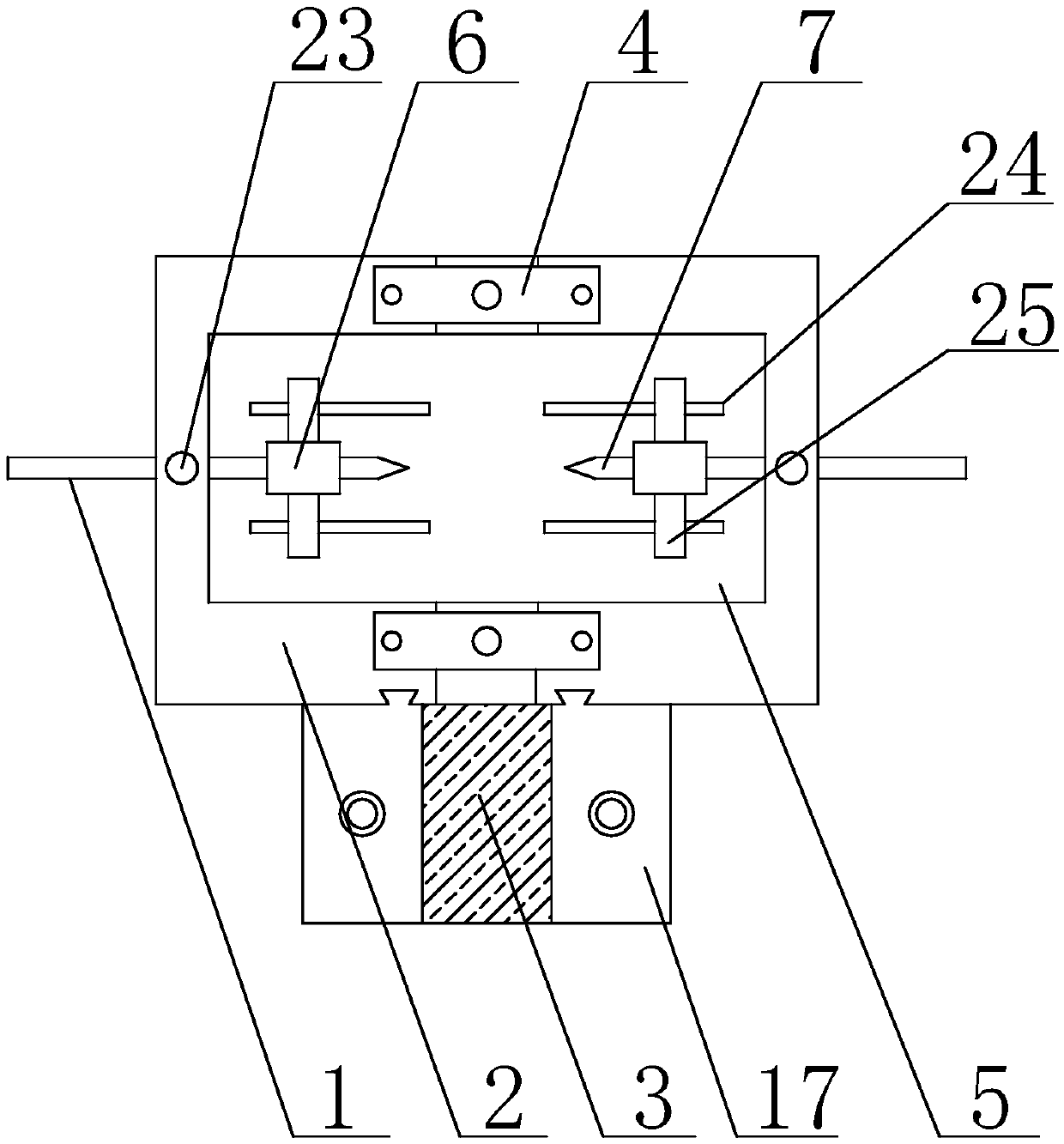

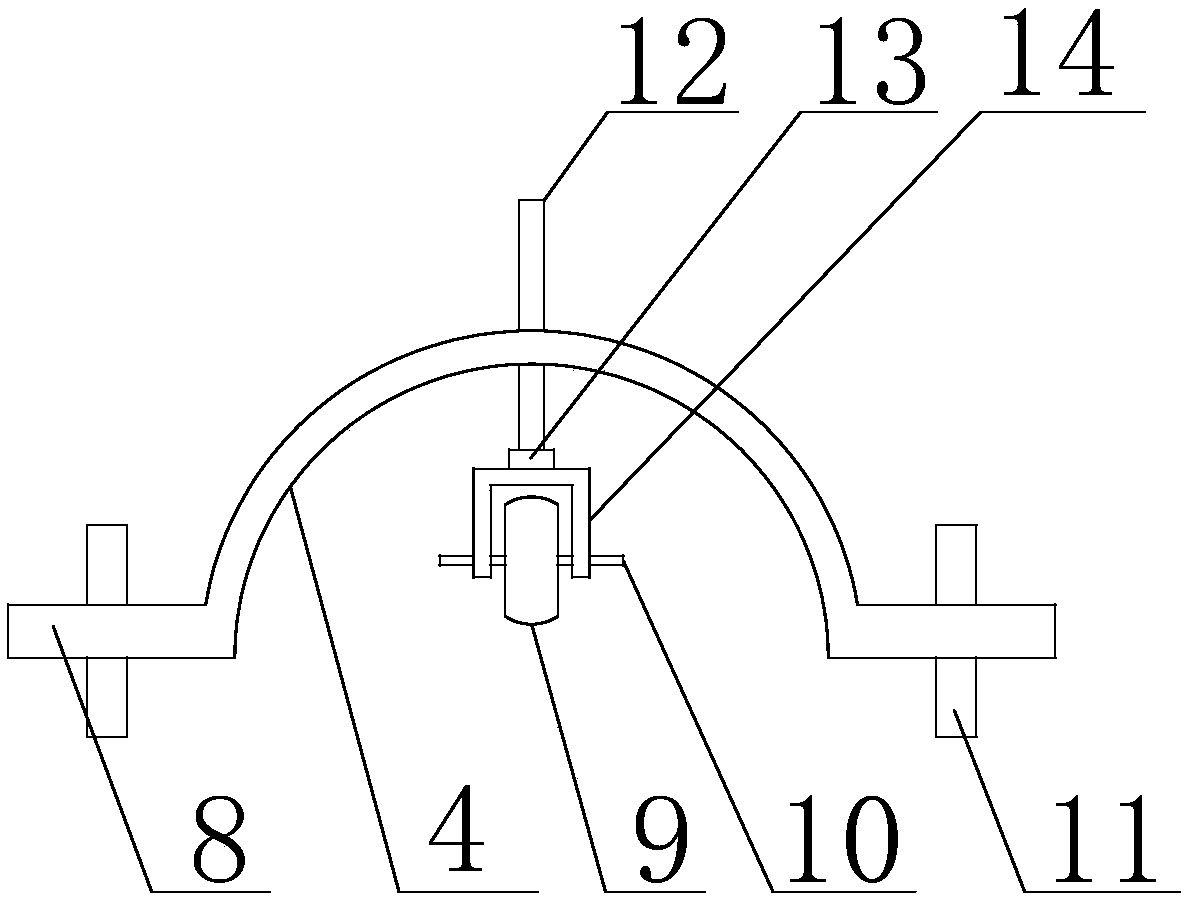

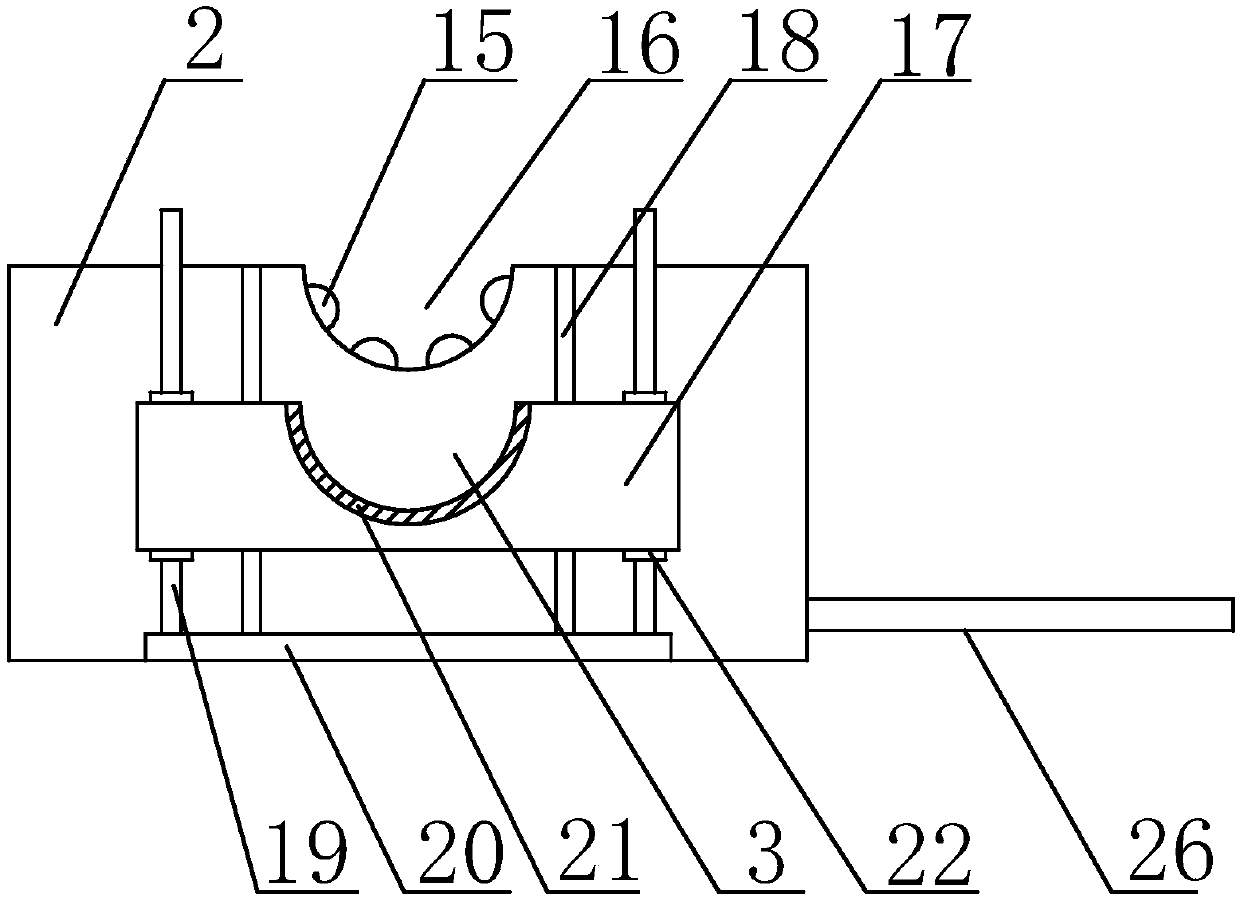

[0027] Such as Figure 1 to Figure 3 As shown, the implementation method of the present invention to prevent damage to the cable wire core includes the following steps: first place the cable to be stripped in the second arc-shaped groove 16 of the support seat 2, rotate the fixing rod 12, and force the roller 9 to The cable is pressed in the second arc-shaped groove 16, and then the movable rod 1 is pushed to force the cutter head 7 to be inserted into the outer skin of the cable, and the adjusting rod 23 is rotated so that the adjusting rod 23 fixes the movable rod 1 on the support base 2 on, and then rotate the stop rod 24 to force the two sides of the cable to be limited by the stop rod 24 to prevent the cable from moving to both sides, and then loosen the fastening ring 22 on the support rod 19 to adjust the movable table 17 height, so that the cable is in the first arc-shaped groove 3, the heating wire in the heating layer 21 is energized, and finally when the cable is pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com