Petrochemical equipment process safety risk analysis and management system

A technology of risk analysis and process safety, applied in manufacturing computing systems, data processing applications, instruments, etc., can solve problems such as irregular use of HAZOP, long HALOPA analysis cycle, lack of field experience, etc., to reduce hidden risks and production losses, Improvement of completeness and efficiency of analysis objects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings and examples, so as to fully understand and implement the process of how to apply technical means to solve technical problems and achieve technical effects in the present invention. It should be noted that, as long as there is no conflict, each embodiment and each feature in each embodiment of the present invention can be combined with each other, and the formed technical solutions are all within the protection scope of the present invention.

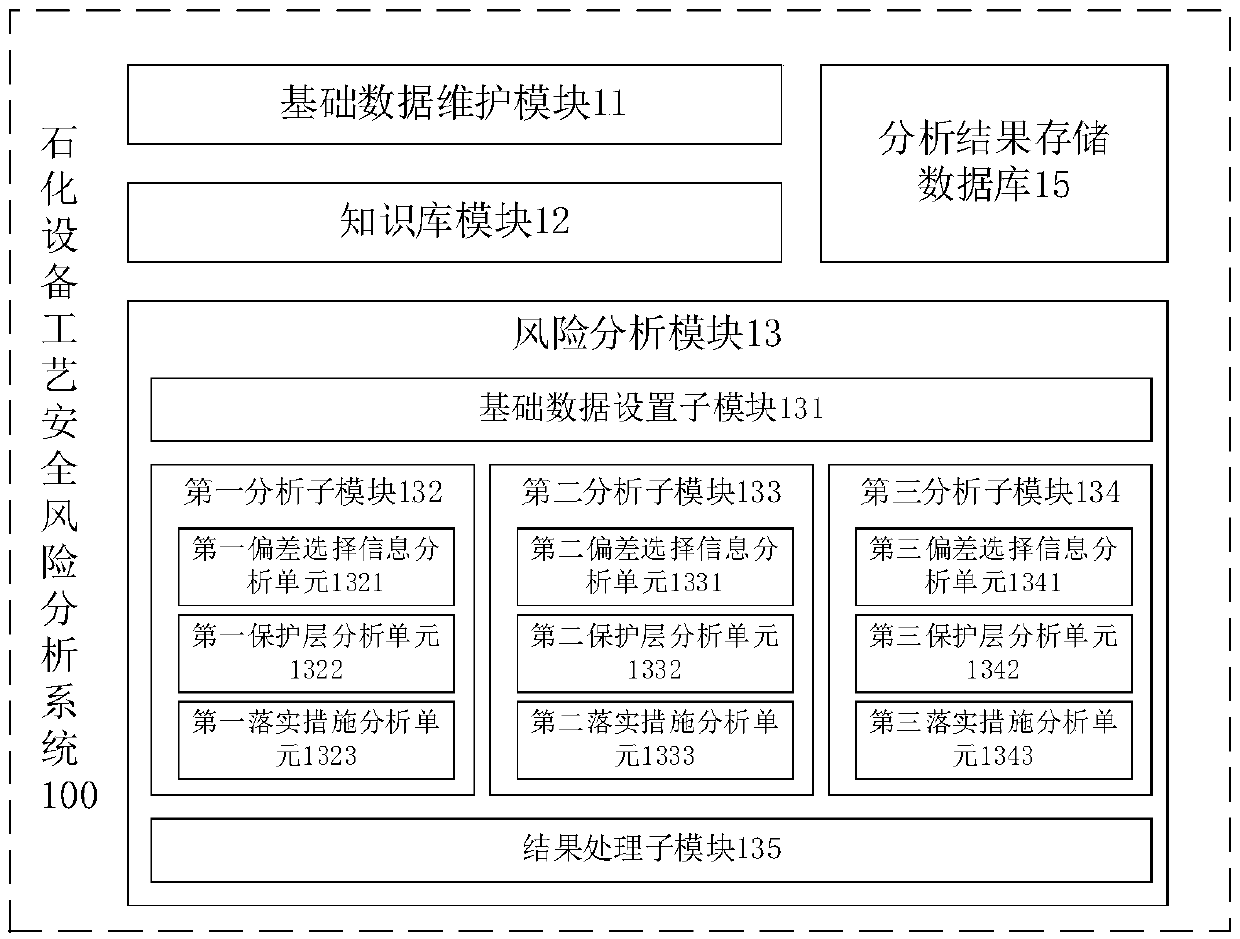

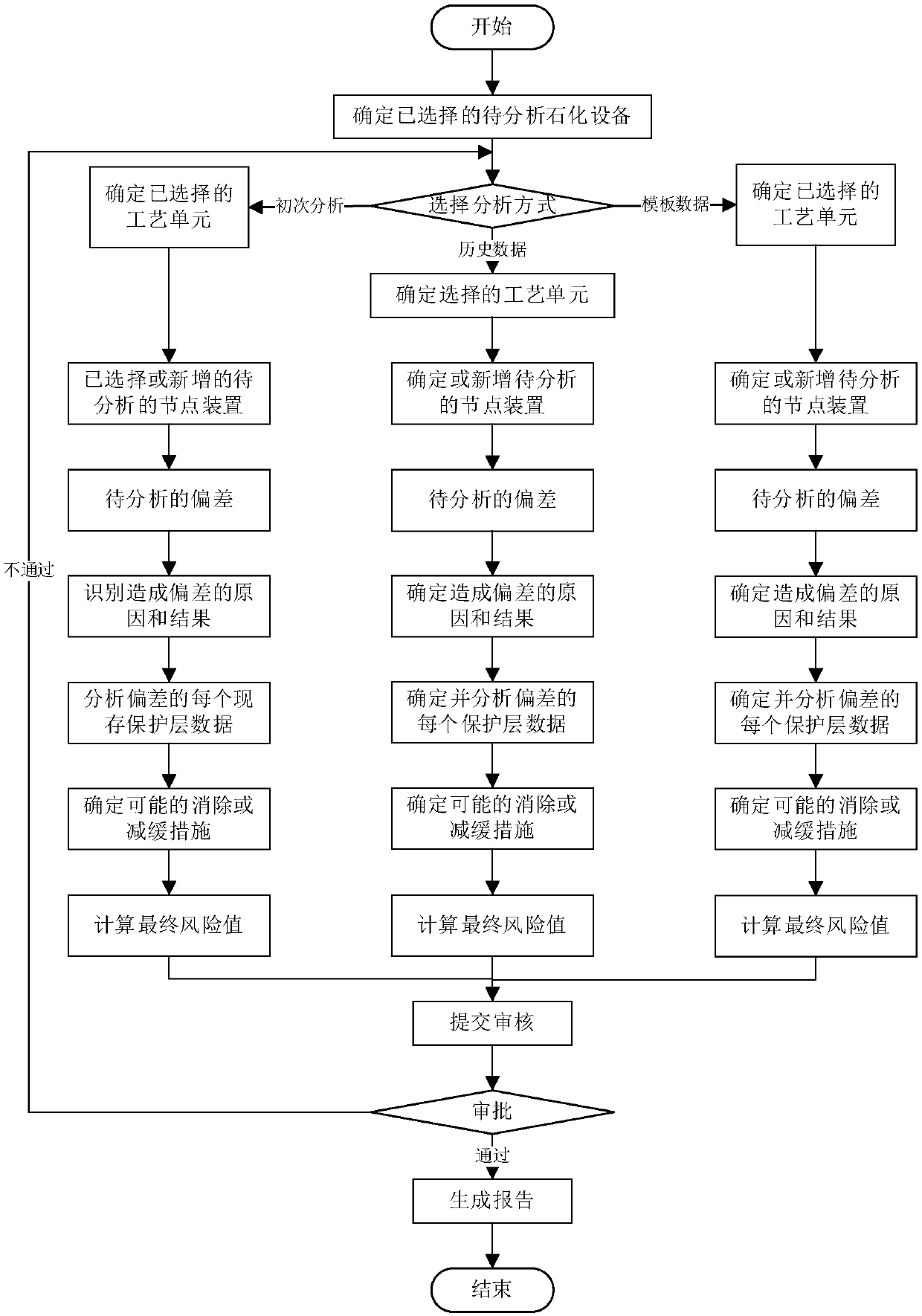

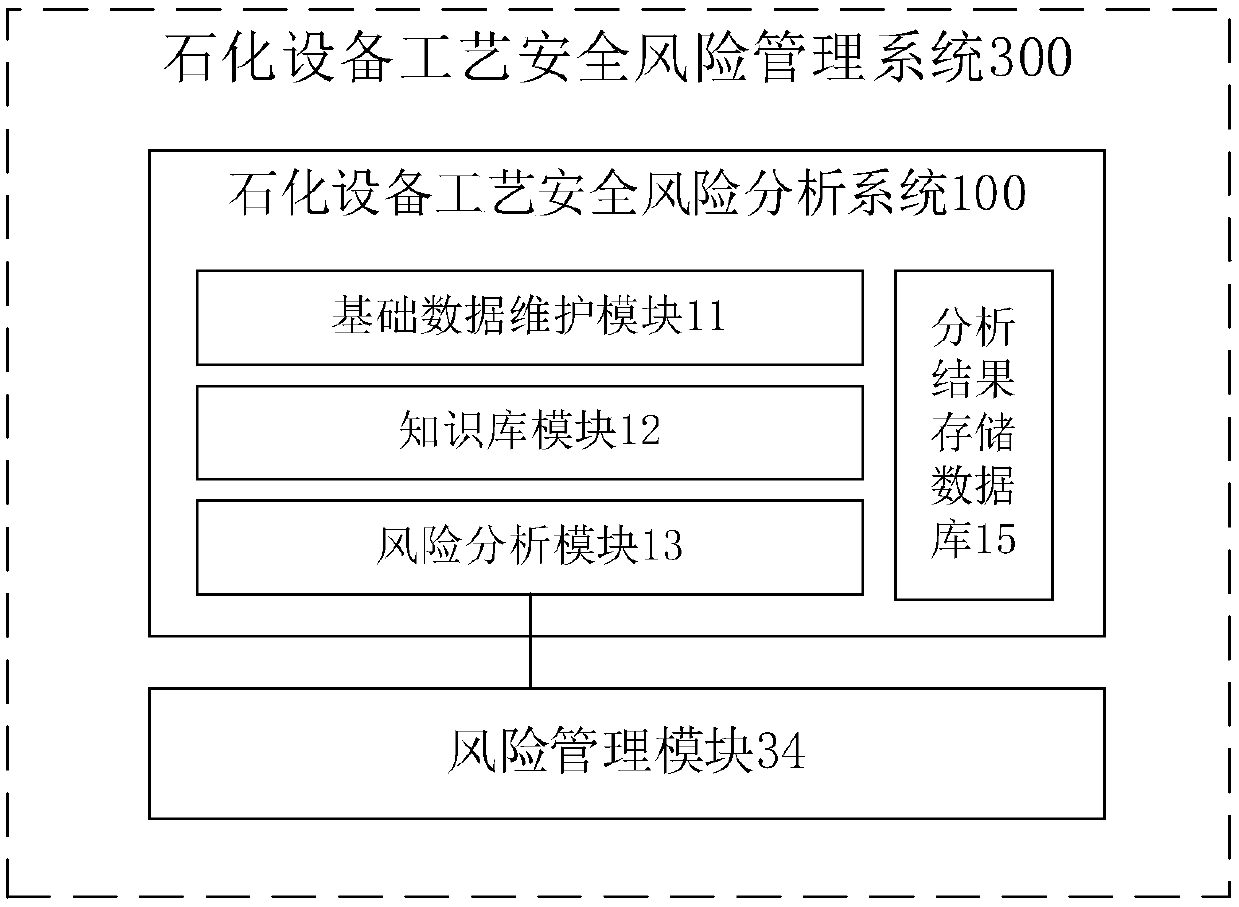

[0025]This application proposes a process safety risk analysis and management system for petrochemical equipment. This method combines traditional risk analysis methods such as HAZOP and LOPA, based on parameters such as the frequency of dangerous events, dangerous equipment, existing safety measures, and application of protection layers, and uses the system's built-in risk assessment model and risk matrix to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com